Resin dissolved solution of resin diamond wire and broken-wire connecting method of resin diamond wire

A technology of resin diamond wire and resin solution, applied in chemical instruments and methods, metal sawing equipment, metal processing equipment, etc., can solve problems such as poor finished products and increased costs, and achieve the effect of reducing processing costs and meeting cutting needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

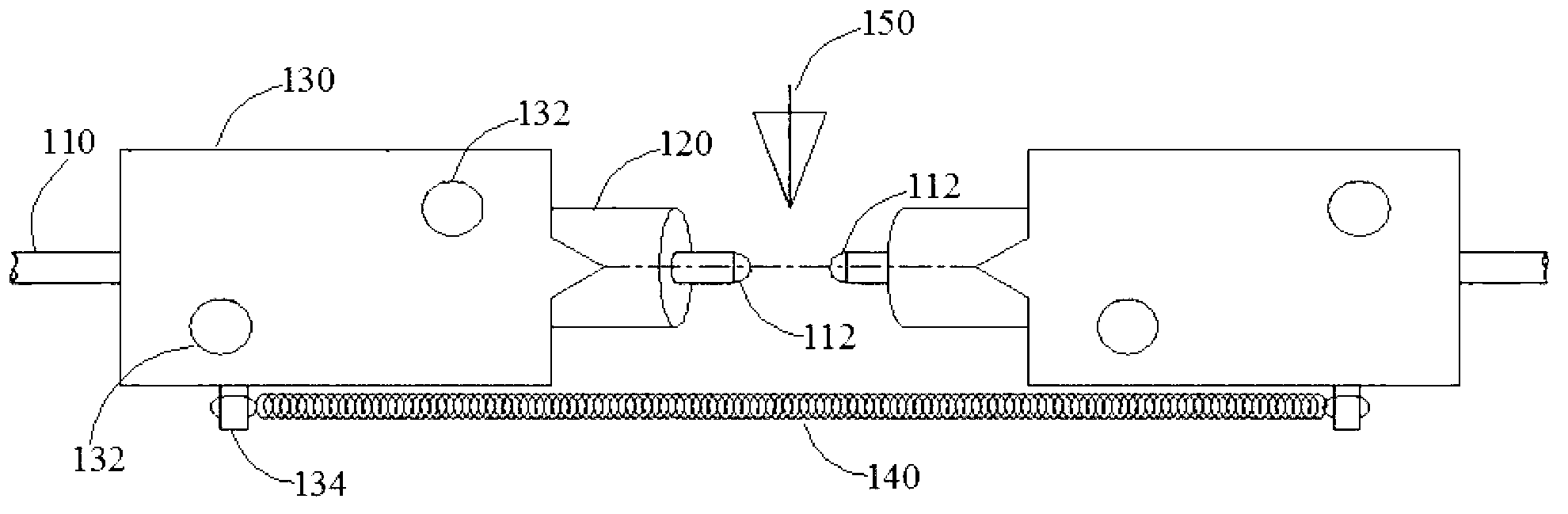

Method used

Image

Examples

Embodiment 1

[0052] 1) Clean the broken ends of the two resin diamond wires.

[0053] 2) Dip the broken end of the resin diamond wire after cleaning into the above-mentioned resin solution of the resin diamond wire to dissolve. The dissolution time is 30 seconds, and the temperature of the resin solution of the resin diamond wire is 90 degrees Celsius.

[0054] Wherein, the mass percentages of each component in the resin solution of resin diamond wire are respectively:

[0055] The dissolving agent is 10% by mass of potassium hydroxide solution, the detergent is 40% by mass of ethanol solution, the solubilizer is 2% by mass of sodium oleate solution, and the balance is water.

[0056] 3) Clean and dry the broken end of the dissolved resin diamond wire;

[0057] 4) Weld the broken ends of the two dried resin diamond wires together.

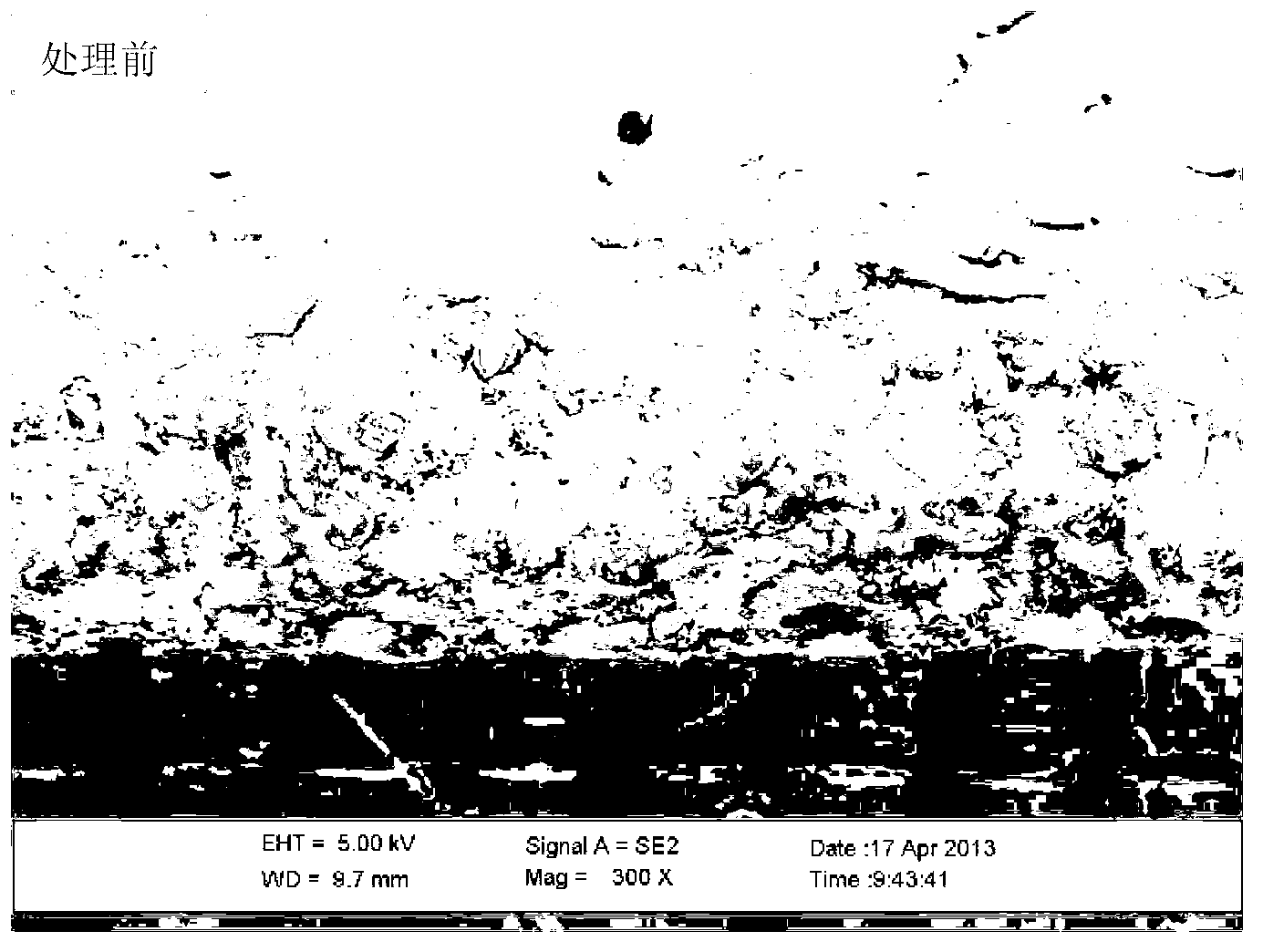

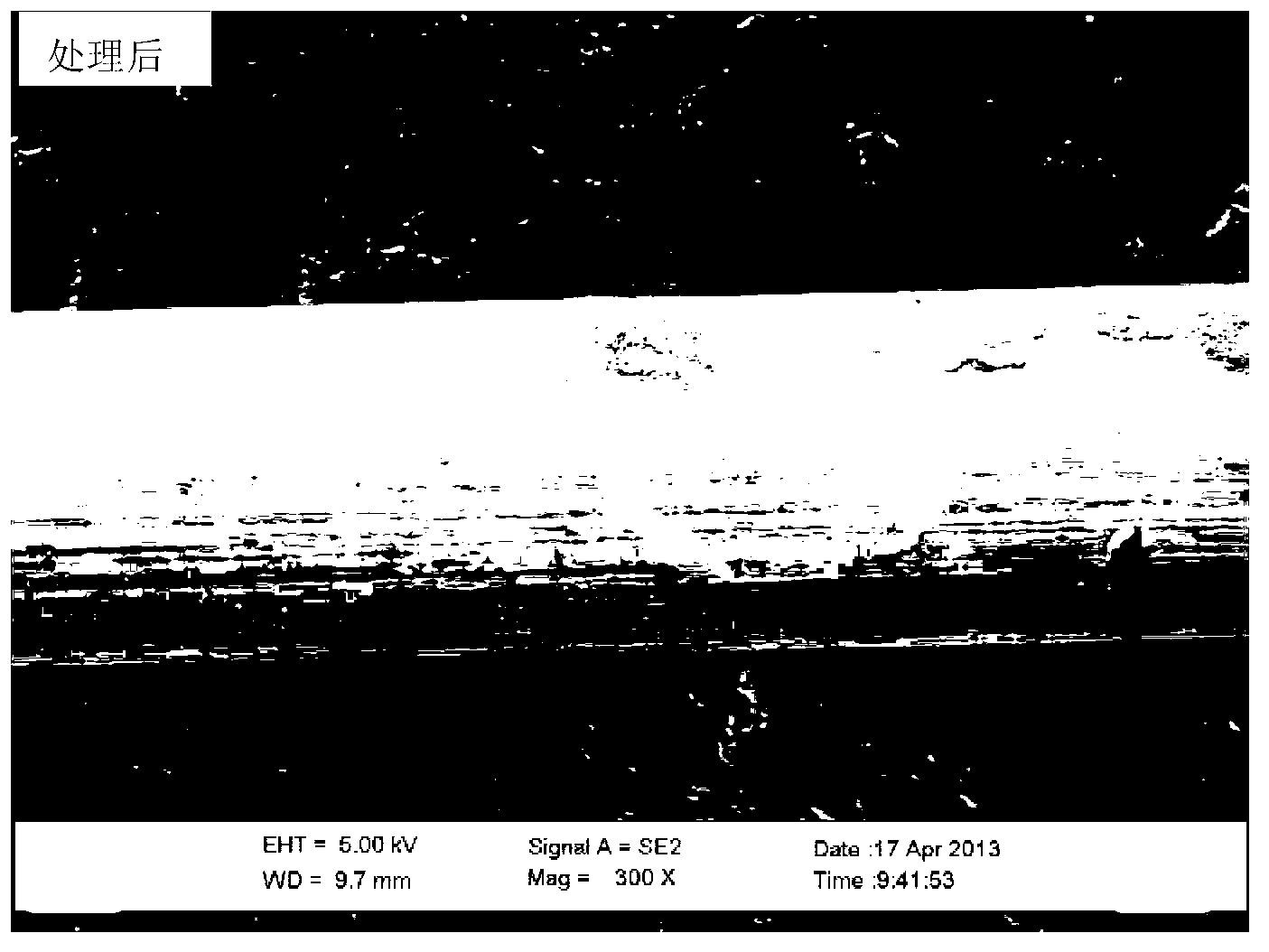

[0058] Please refer to figure 2 , this figure shows the original state diagram before the resin diamond wire resin layer is dissolved, using the resin solu...

Embodiment 2

[0061] 1) Clean the broken ends of the two resin diamond wires.

[0062] 2) Dip the broken end of the resin diamond wire after cleaning into the above-mentioned resin solution of the resin diamond wire to dissolve, the dissolution time is 60 seconds, and the temperature of the resin solution of the resin diamond wire is 70 degrees Celsius.

[0063] Wherein, the mass percentages of each component in the resin solution of resin diamond wire are respectively:

[0064] The dissolving agent is 50% by mass sodium hydroxide solution, the detergent is 30% by mass isopropanol solution, the solubilizer is 5% by mass polyoxyethylene lauryl ether solution, and the balance is water.

[0065] 3) Clean and dry the broken end of the dissolved resin diamond wire;

[0066] 4) Weld the broken ends of the two dried resin diamond wires together.

[0067] The wire saw obtained after welding by the resin diamond wire broken wire connection method is subjected to a tension test after annealing and ...

Embodiment 3

[0069] 1) Clean the broken ends of the two resin diamond wires.

[0070] 2) Dip the broken end of the resin diamond wire after cleaning into the above-mentioned resin solution of the resin diamond wire to dissolve. The dissolution time is 300 seconds, and the temperature of the resin solution of the resin diamond wire is 30 degrees Celsius.

[0071] Wherein, the mass percentages of each component in the resin solution of resin diamond wire are respectively:

[0072] The dissolving agent is 0.05% by mass percentage of calcium hydroxide solution and 30% sodium hydroxide solution, the detergent is 30% by mass percentage of ethanol solution and 5% isopropanol solution, and the solubilizer is 2% by mass percentage of Polyoxyethylene fatty alcohol solution, the balance is water.

[0073] 3) Clean and dry the broken end of the dissolved resin diamond wire;

[0074] 4) Weld the broken ends of the two dried resin diamond wires together.

[0075] The wire saw obtained after welding b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com