ADSS optical cable air-connection box

A splice box, optical cable technology, applied in the field of ADSS optical cable installation, can solve the problem of inability to complete the mechanical connection of two optical cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

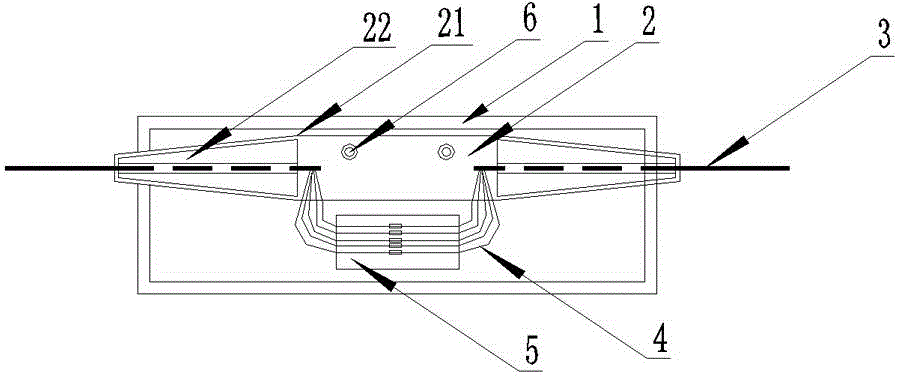

[0023] When the gear distance is between 100m and 300m, the force receiving body 2 includes an outer shell 21 and a shuttle-shaped clamp 22. The outer shell 21 is a hollow shell with a columnar structure in the middle and symmetrical tapered ends at both ends. , the shuttle-shaped clamp 22 is two and symmetrically arranged in the tapered cavity of the outer shell, its structure is compatible with the tapered cavity, the shuttle-shaped clamp 22 is composed of several shuttle-shaped bodies, so The shuttle-shaped bodies are evenly distributed around the central axis of the outer casing 21 to form an optical cable channel, gaps are left between the shuttle-shaped bodies, and wear-resistant bushings are provided on the inner surface of the optical cable channel.

[0024] Preferably, the outer casing 21 is made of high-strength aluminum alloy, and the shuttle clamp 22 is made of weather-resistant engineering plastics.

[0025] After the optical cable 3 penetrates, the shuttle clamp ...

Embodiment 2

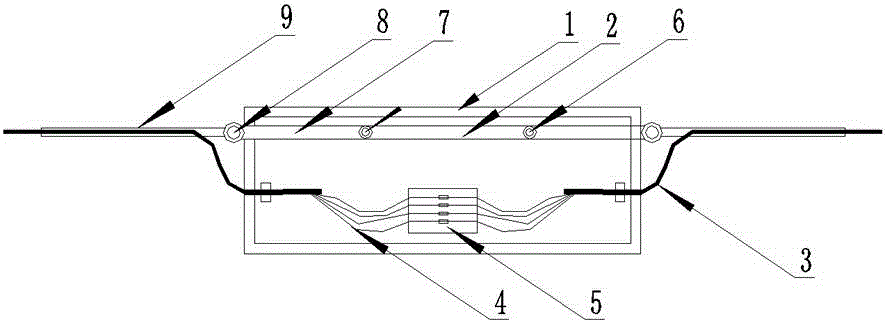

[0027] When the gear distance is greater than 300 meters, the stressed body 2 includes a rod body 7, a circular hanging ring 8 and a pre-twisted wire 9. The rod body 7 is a rod-shaped structure, and its two ends extend to the outside of the box body 1. The circular hanging rings 8 are arranged symmetrically at both ends of the rod body 7, and are respectively movably connected with the pre-twisted wires 9, and the pre-twisted wires 9 hold the terminals of the two optical cables 3 respectively.

[0028] Preferably, the rod body 7 is made of high-strength aluminum alloy.

[0029] During use, two pre-twisted wires 9 are respectively held to hold two optical cables 3, and then the pre-twisted wires 9 are hung on the circular hanging ring 8, so that the left and right two optical cables 3 are connected through the rod body 7, thereby realizing Stress; Wherein, the pre-twisted wire 9 can select different models according to the gauge distance and the outer diameter of the optical ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com