Trailer bogie framework for standard EMU (Electric Multiple Units)

A technology of EMUs and bogies, which is applied in the field of trailer frames, can solve the problems of high stress and low stress in the connection area between the brake mounting seat and the beam, and achieve the effects of improving the overall strength, improving the stress level, and reducing the torsional condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

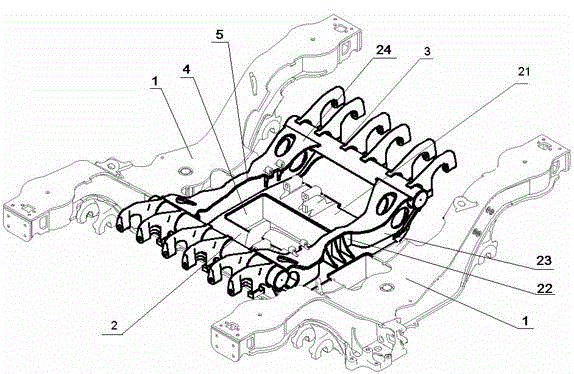

[0009] refer to figure 1 , the main body is composed of two side beams 1, a cross beam 2 and two brake beams 3, the side beams and the main body of the cross beam are both box-type welded structures, and are connected by plug-in connection to reduce the geometric change of the section; the side beams Various mounting seats are welded on the beam and the beam respectively. The upper cover plate 21 of the cross beam, the inner vertical plate 22 of the brake beam, the outer vertical plate 23 and the upper cover plate 24 of the brake beam form a box-shaped structure in the connection area, so as to realize the transition connection between the brake beam 3 and the cross beam 2, thereby increasing the The loaded section of this connection area (increasing the stressed section at the root of the cantilever structure) improves its stress level to improve the reliability of this area. The brake beam inner vertical plate 22 and the upper cover plate 24 are designed as an integrated st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com