OPGW optical fiber dual-stress accelerated life comprehensive evaluation method

A technology for accelerated life and comprehensive evaluation, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficulty in obtaining failure data, complex failure mechanisms, and few failure samples, and achieve a simple test implementation process and avoidance. The effect of large sample size and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

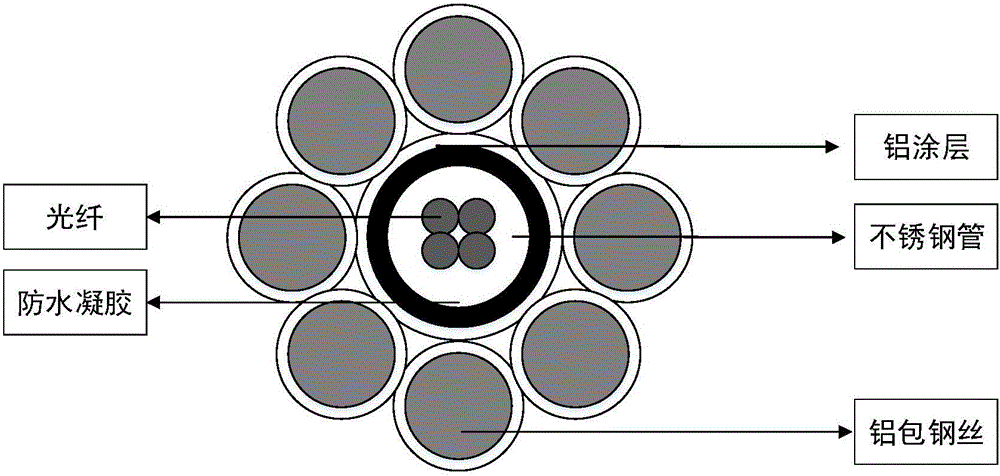

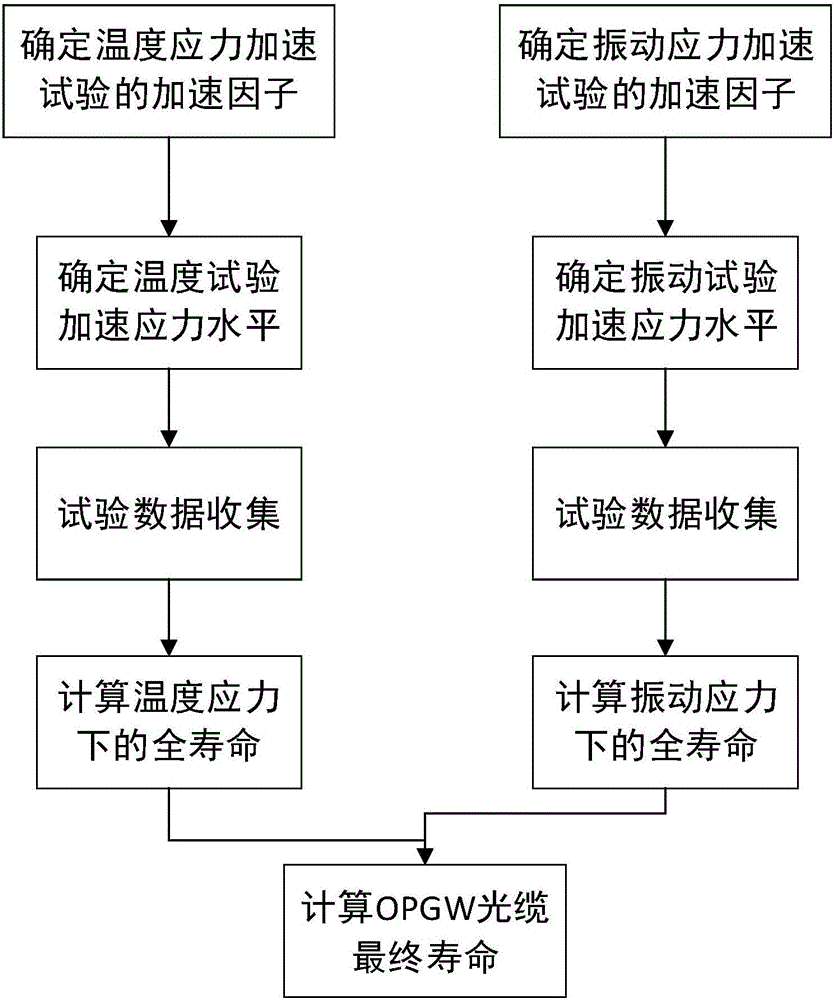

[0028] The present invention takes the OPGW optical cable as the object, and its relevant description is shown in the accompanying drawings and technical solutions. Flowchart of dual stress accelerated life comprehensive evaluation of OPGW optical cable, such as figure 1 shown. The OPGW optical cable dual-stress accelerated life comprehensive evaluation method is used to evaluate its reliable life. Based on the idea of cumulative damage, according to the working characteristics of the OPGW optical cable, the working cycle is carried out under the conditions of accelerated temperature stress and accelerated vibration stress. Under the conditions of the failure mechanism, the failure process is accelerated, the life under normal stress is further extrapolated, and it has good adaptability to the OPGW optical cable with complex composition and failure mechanism.

[0029] This method is aimed at the main stress damage types suffered by the OPGW optical cable in the working envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com