Low-floor railway vehicle bogie

A rail vehicle and bogie technology, which is applied in the direction of the bogie, the device for lateral relative movement between the chassis and the bogie, and the components of the railway car body. , Super statically indeterminate bearing unevenness and other problems, to improve the overall bearing state, reduce stress, and improve the effect of stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

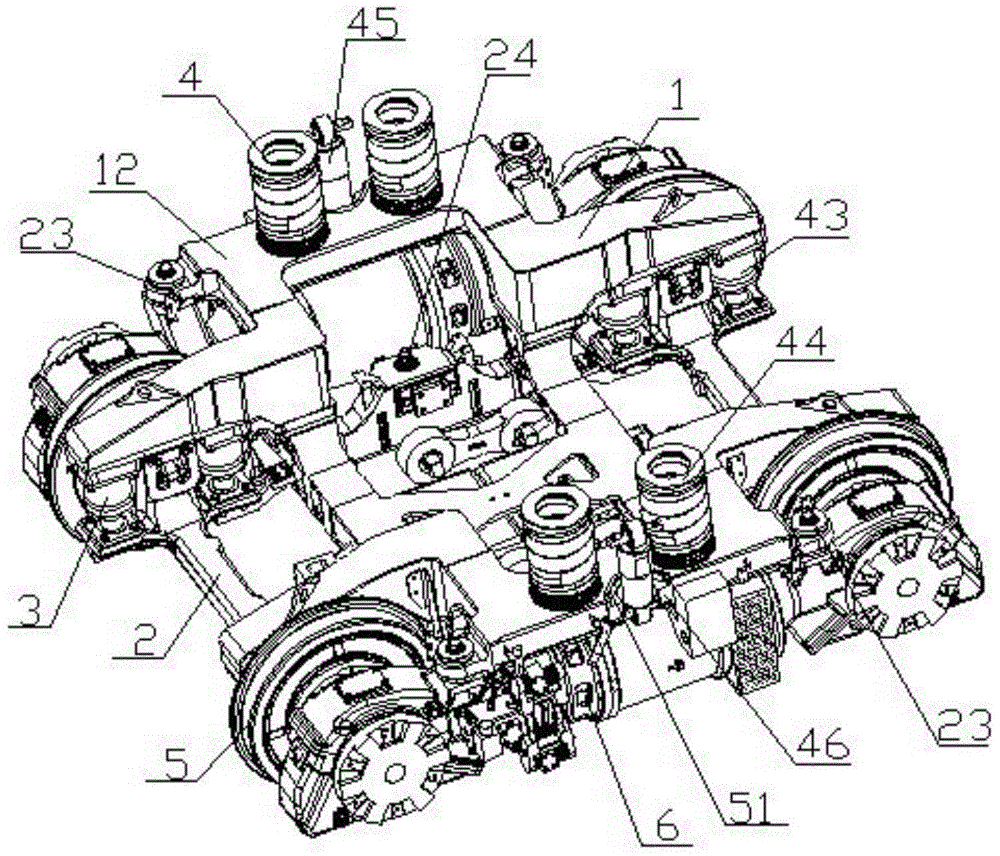

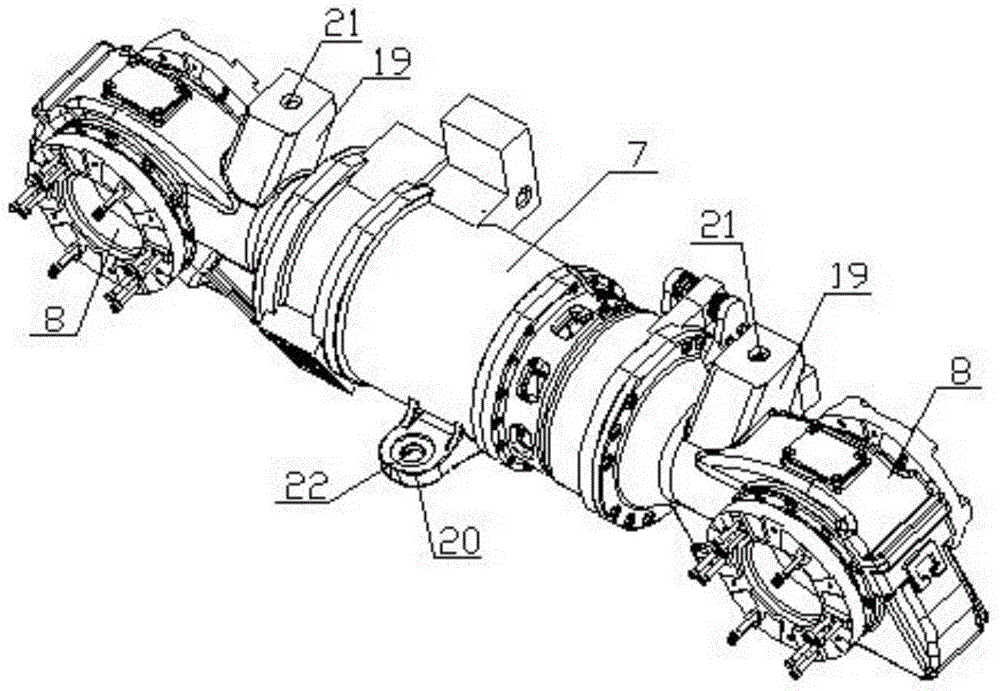

[0029] Such as figure 1 As shown, the present invention provides a low-floor rail vehicle bogie, which includes a frame 1, an axle bridge 2, a primary suspension 3, a secondary suspension 4, a wheel 5, and a motor gear box 6. There are two motor gearbox components 6 which are respectively hung on the outside of both sides of frame 1, such as image 3 As shown, the motor gearbox composition 6 includes a traction motor 7 in the middle and gearboxes 8 at both ends. One traction motor 7 drives two gearboxes 8 at the same time, the wheels 5 are four independent wheels, and the four gearboxes 8 drive four respectively. The wheel 5 rotates.

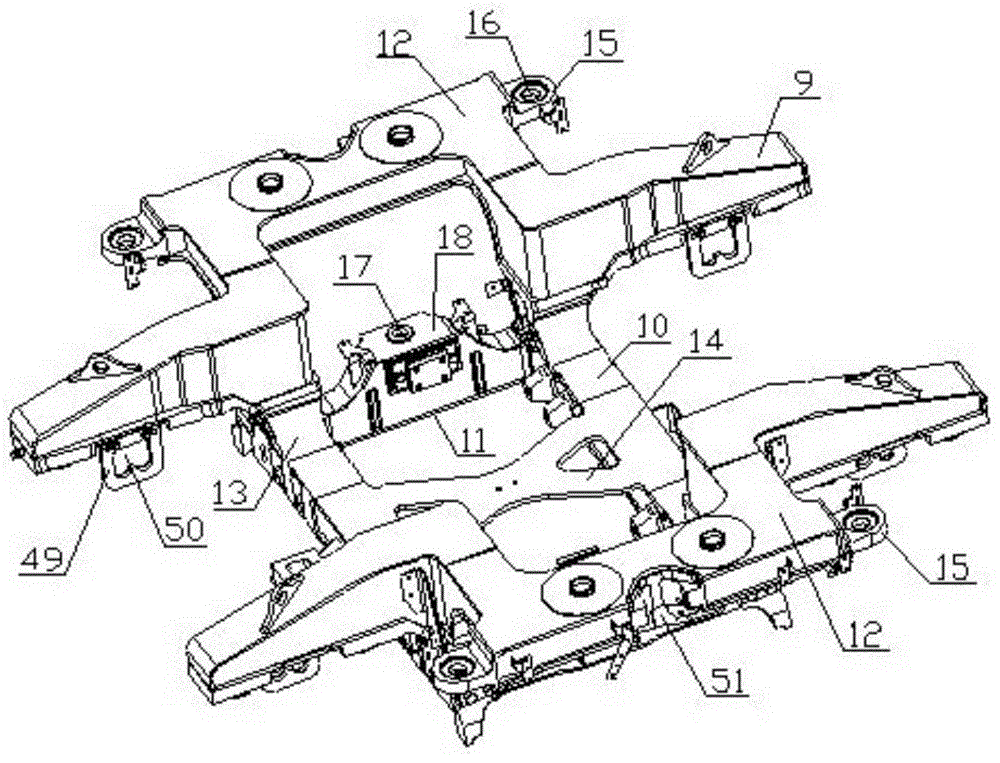

[0030] Such as figure 1 with figure 2 As shown, the frame 1 includes two side beams 9, two cross beams 10, and two longitudinal beams 11. The center of the two side beams 9 respectively protrudes out of a cantilever bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com