Production method for producing shock toughness of pipe coupling material of hot rolled oil well

A technology of impact toughness and production method, applied in the direction of metal rolling, etc., to achieve the effect of excellent toughness, refinement of grains, and inhibition of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

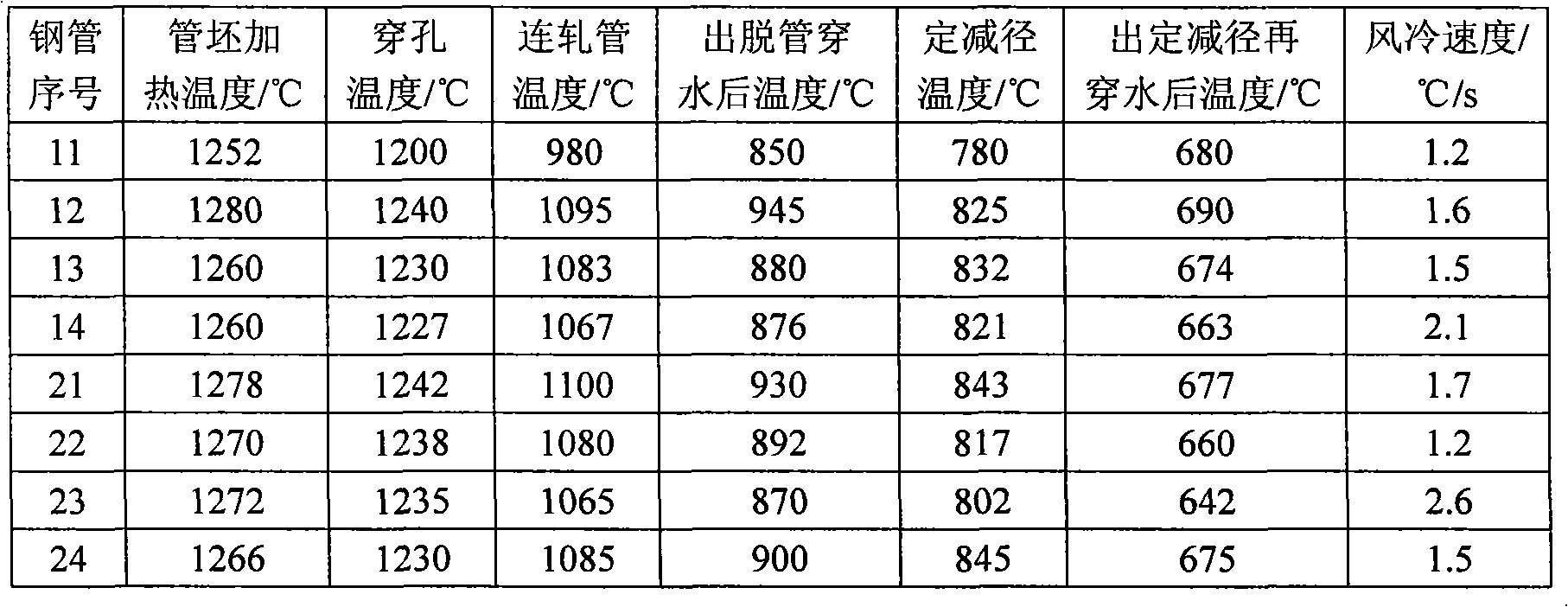

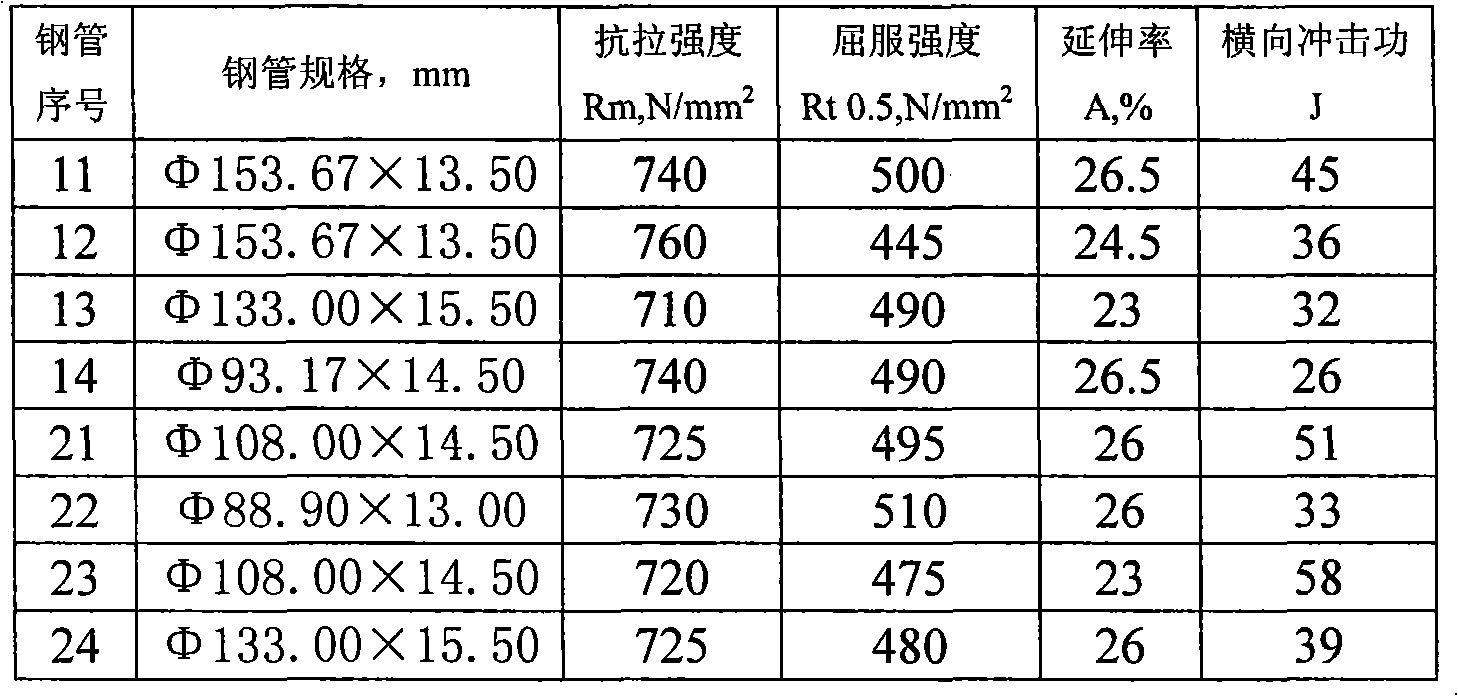

[0013] The weight percentage of a chemical composition is: C: 0.24% ~ 0.40%, Si: 0.17% ~ 0.60%, Mn: 1.30% ~ 1.70%, P≤0.025%, S≤0.010%, Ti: 0.010% ~ 0.030% , N≤0.008%; the balance is iron and unavoidable impurities. The specifications are: Φ153.67×13.50mm, Φ127×13.50mm, Φ88.9×13mm, Φ93.17×14.5mm, Φ108×14.50mm, Φ133×15.50mm oil well pipe coupling materials as an example.

[0014] During the implementation process, the tube blank of the above-mentioned composition steel is heated to 1250°C-1280°C, and kept for 2h-3h; the tube blank is pierced into a capillary tube at 1200°C-1250°C; The steel pipes after continuous rolling and stripping are rapidly cooled to a certain temperature above Ar3 (850°C-950°C); after rapid cooling, the average temperature of the steel pipes in the traverse chain is 15s-30s; (750°C~850°C) directly into the sizing machine to ensure final rolling in the metastable austenite zone not lower than Ar3; after sizing and final rolling, spray water or steam mist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com