Patents

Literature

35results about How to "Realize civilized production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

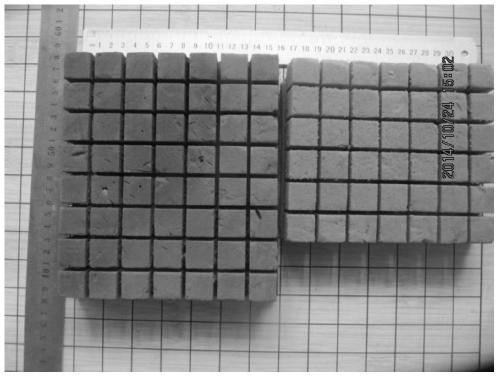

Degradable foam composition for seedling raising or flower arrangement, and manufacturing method and application thereof

The invention relates to the field of plant cultivation media, and particularly provides a degradable foam composition for seedling raising or flower arrangement. The degradable foam composition for seedling raising or flower arrangement is prepared from the following raw materials: phenol and polyformaldehyde in a mole ratio of 1:(1.4-2.5), water (24mL for every mole of phenol), urea (accounting for 10-25 wt% of the phenol), pulp board (accounting for 6-15 wt% of the phenol), starch (accounting for 6-15 wt% of the phenol), and 10 wt% polyvinyl alcohol (accounting for 2-15 wt% of the phenol). The invention also provides a preparation method and application of the degradable foam composition for seedling raising or flower arrangement. The reaction speed of the preparation method is greatly higher than that of the traditional method, and no wastewater is generated in the whole process. The free formaldehyde content and free phenol content of the prepared product are lower than the national standard, so the product is completely harmless; and the seedling raising container or flower mud prepared from the degradable foam composition is suitable for demands of plants for physical properties of the nutrient and medium.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

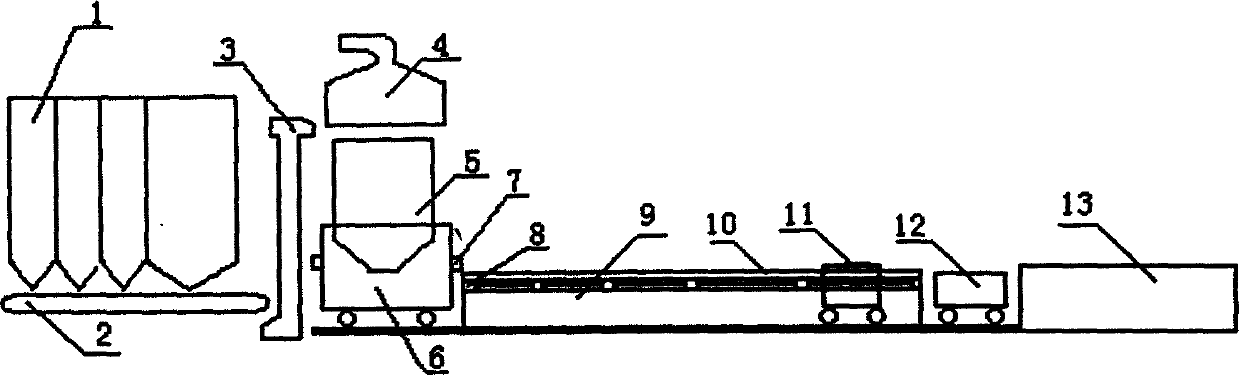

Multifunctional production line of light gypsum panel

InactiveCN1583382ASolve pollutionThe problem of dust prevention is prominentMixing operation control apparatusCeramic shaping apparatusGypsum blockManufacturing line

A mechanized production line features that regulating the shape and sizes of mould on its shaping platform can produce different light gypsum plates, such as 3D reinforcing gypsum plate, dual-fibre reinforced gypsum plate, building gypsum block and reinforced insulating gypsum plate.

Owner:北京清华建筑工程咨询公司

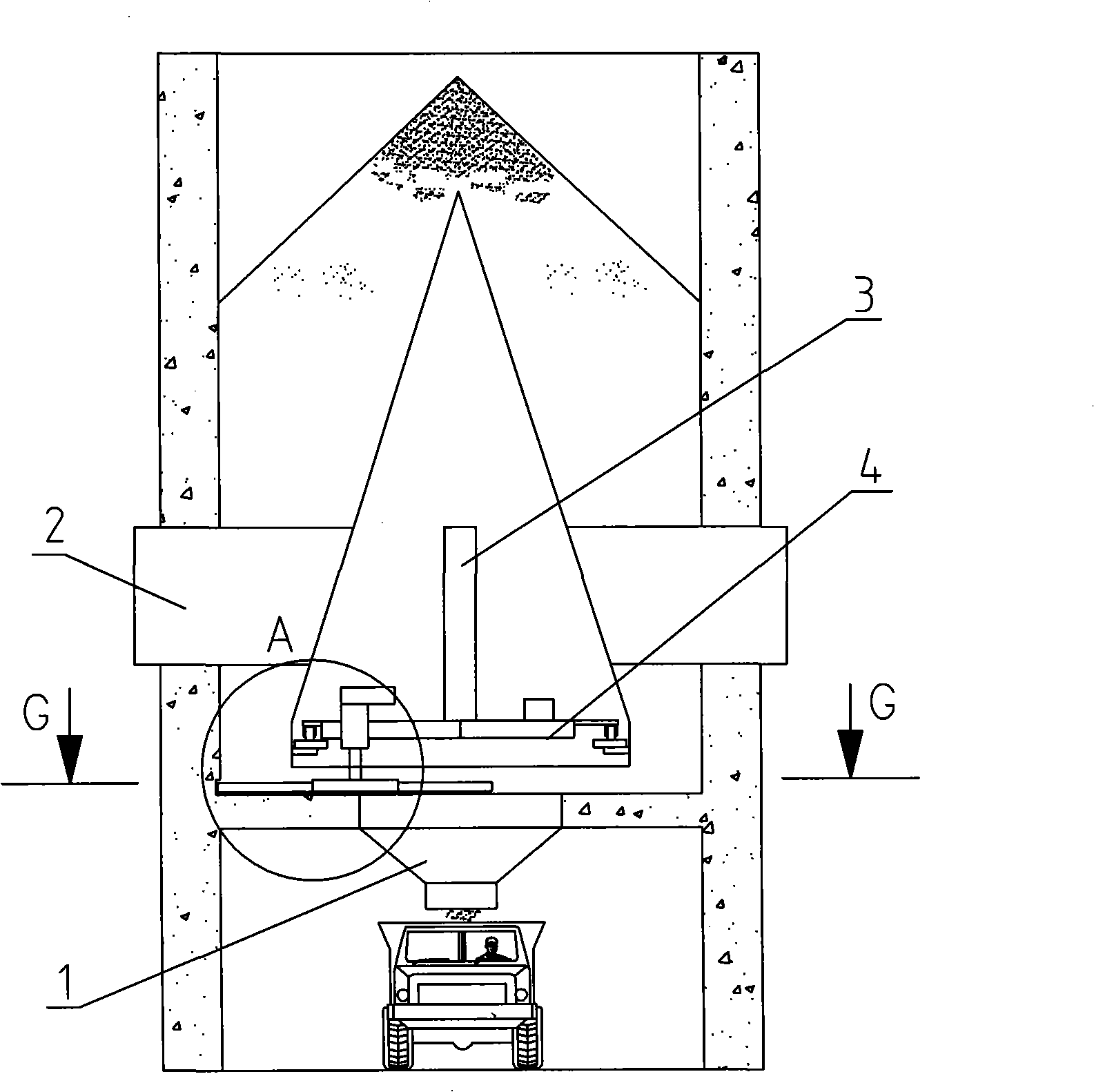

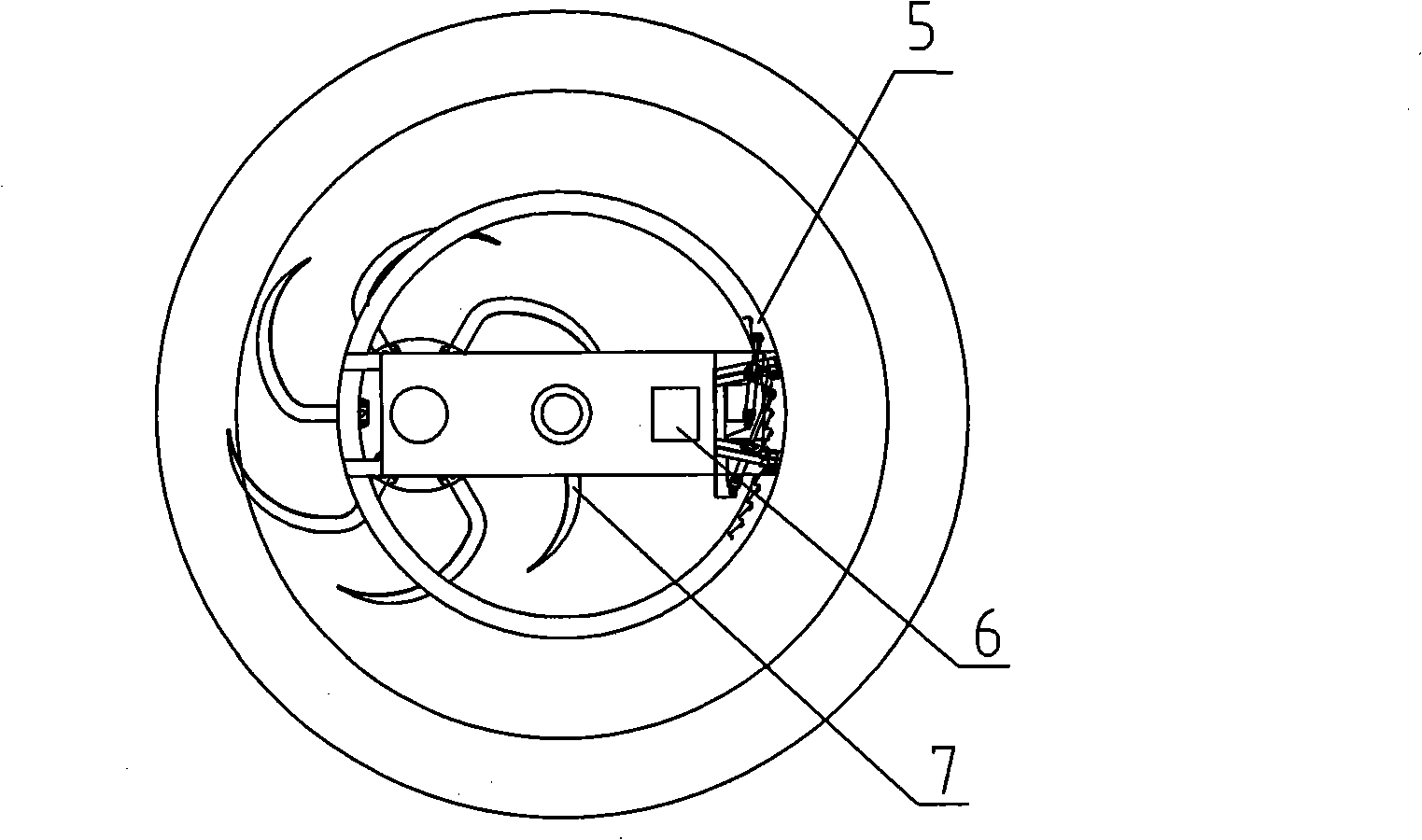

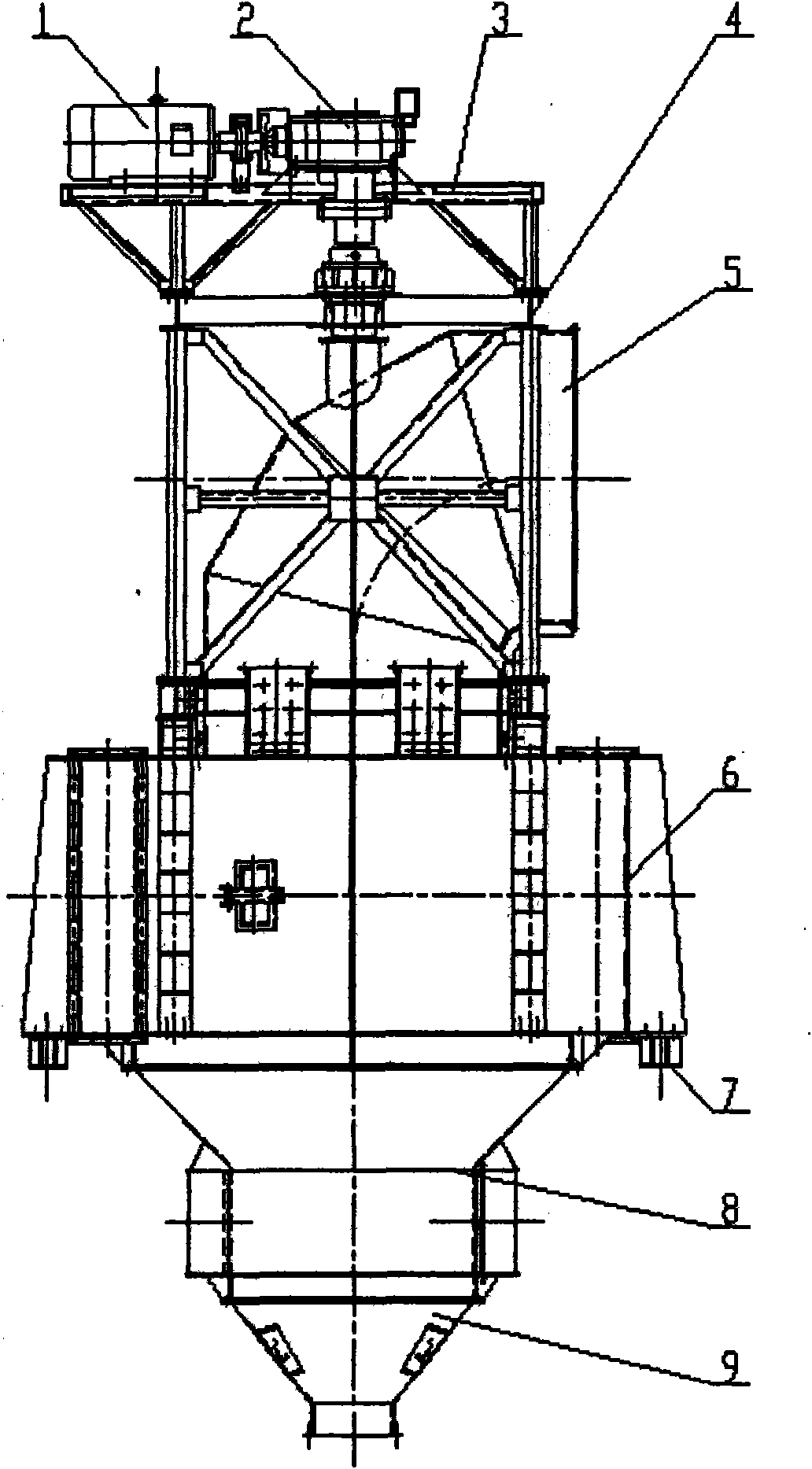

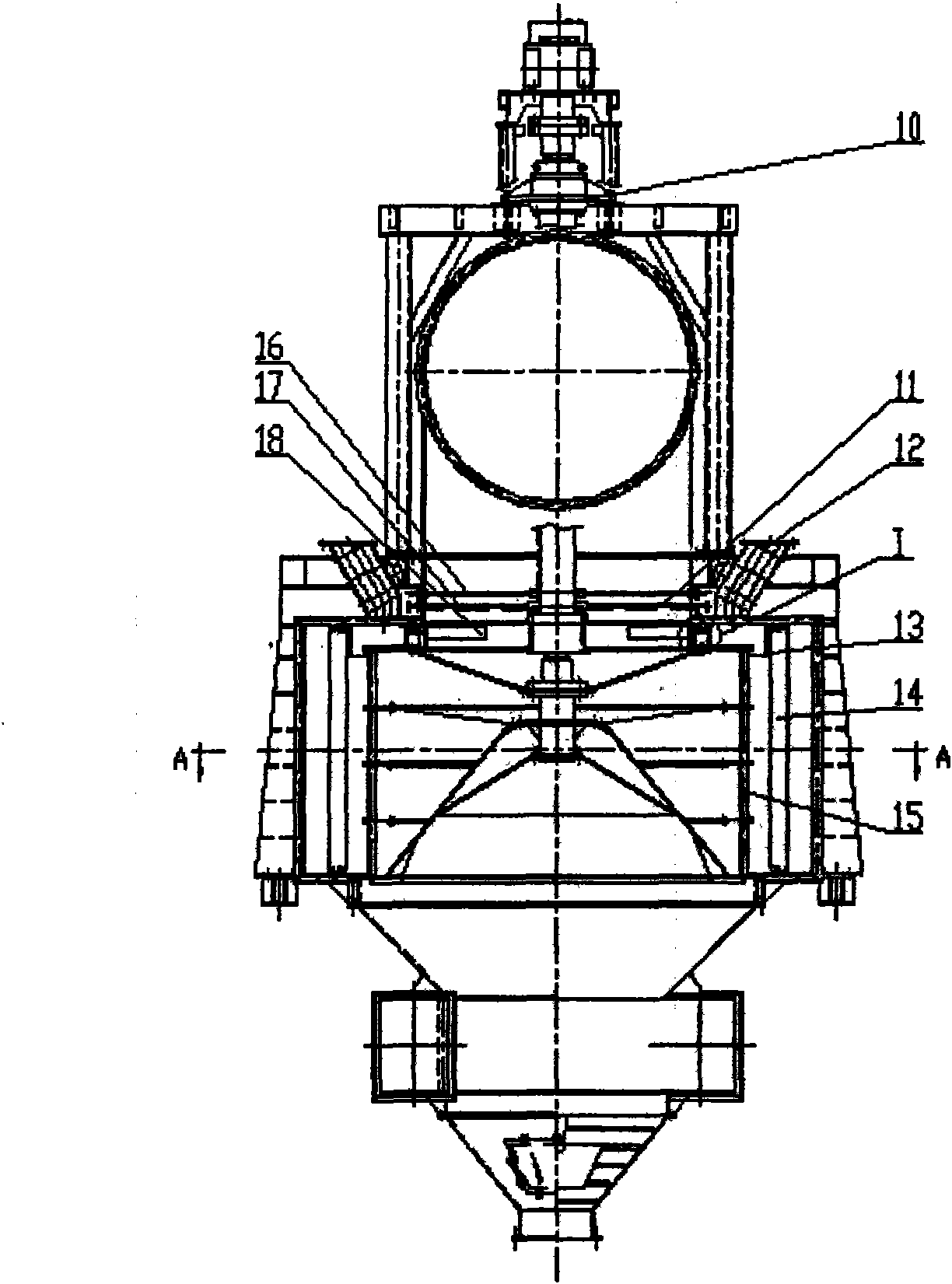

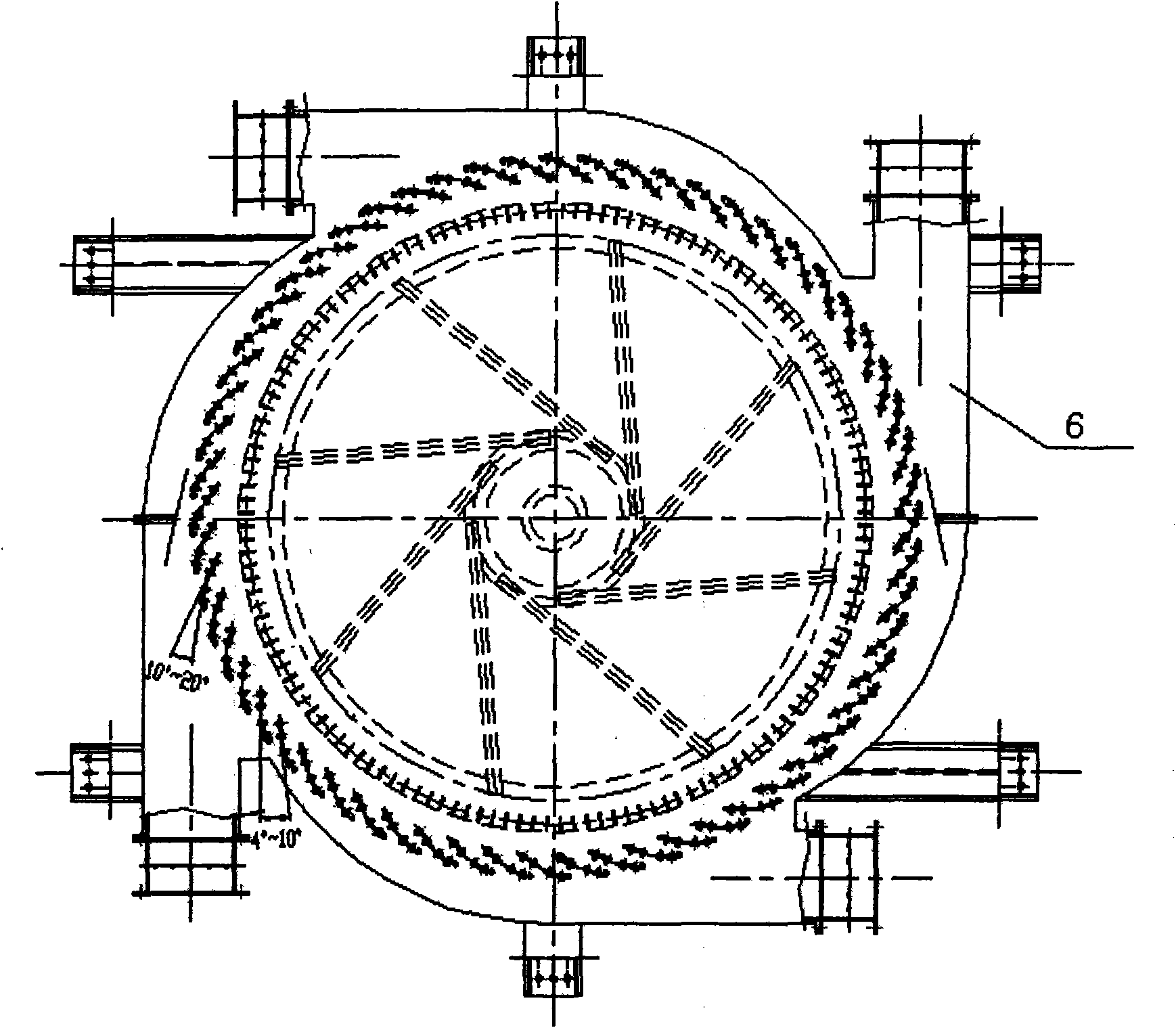

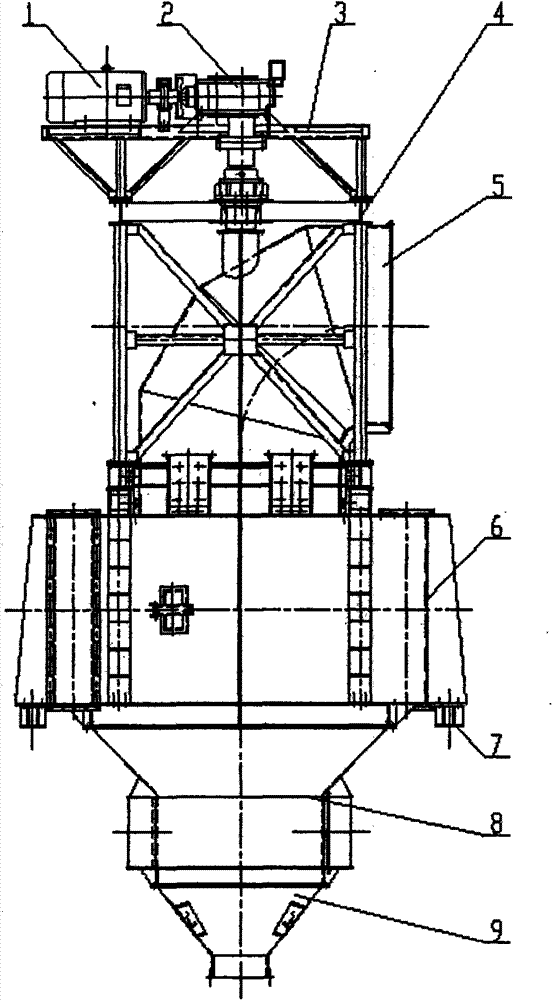

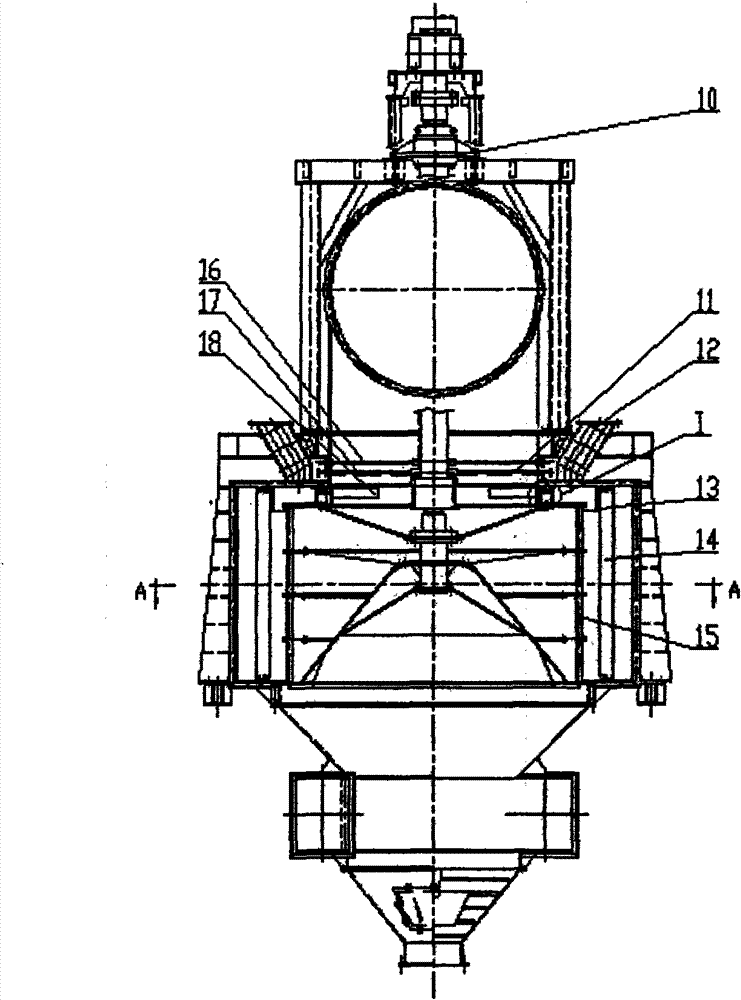

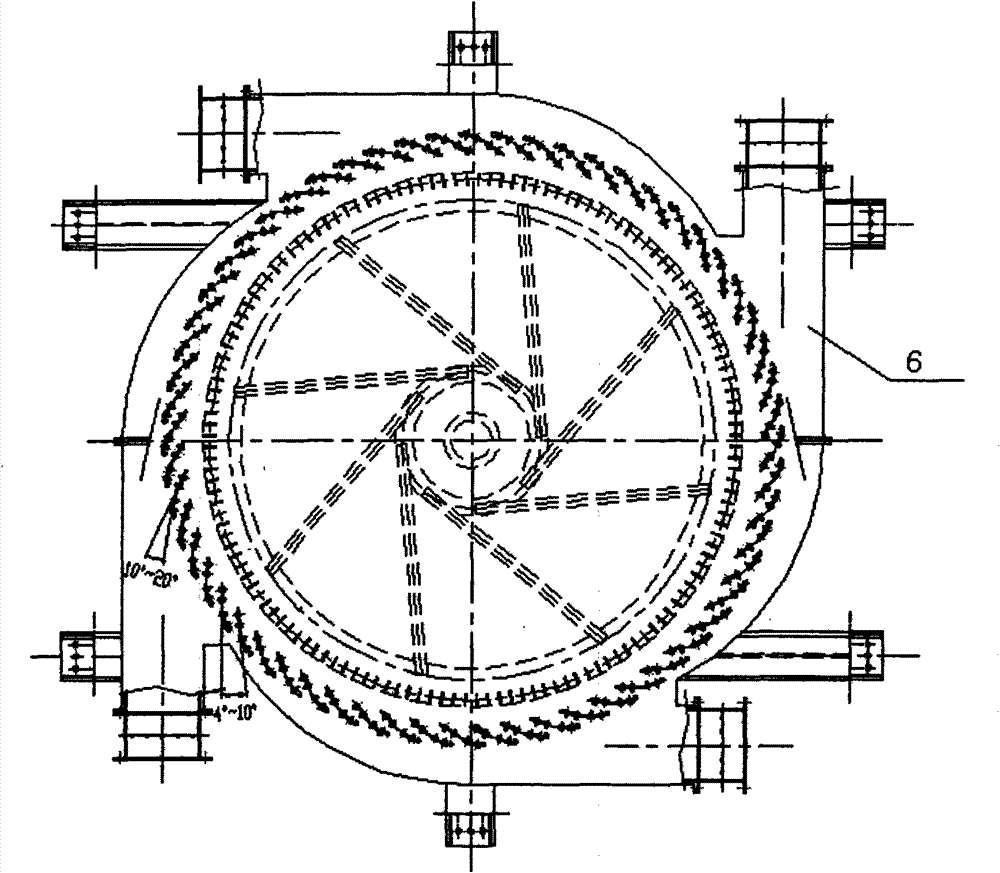

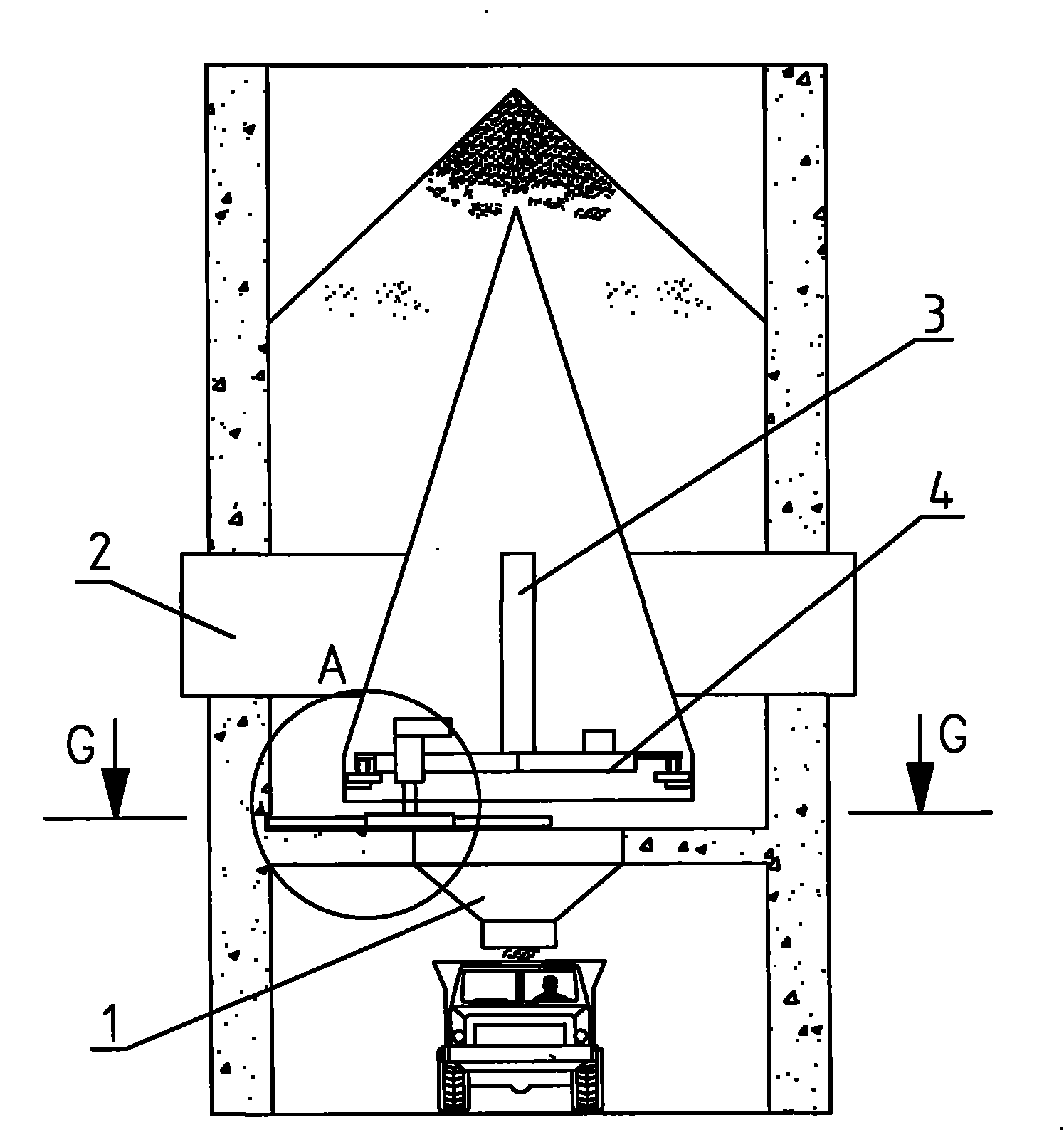

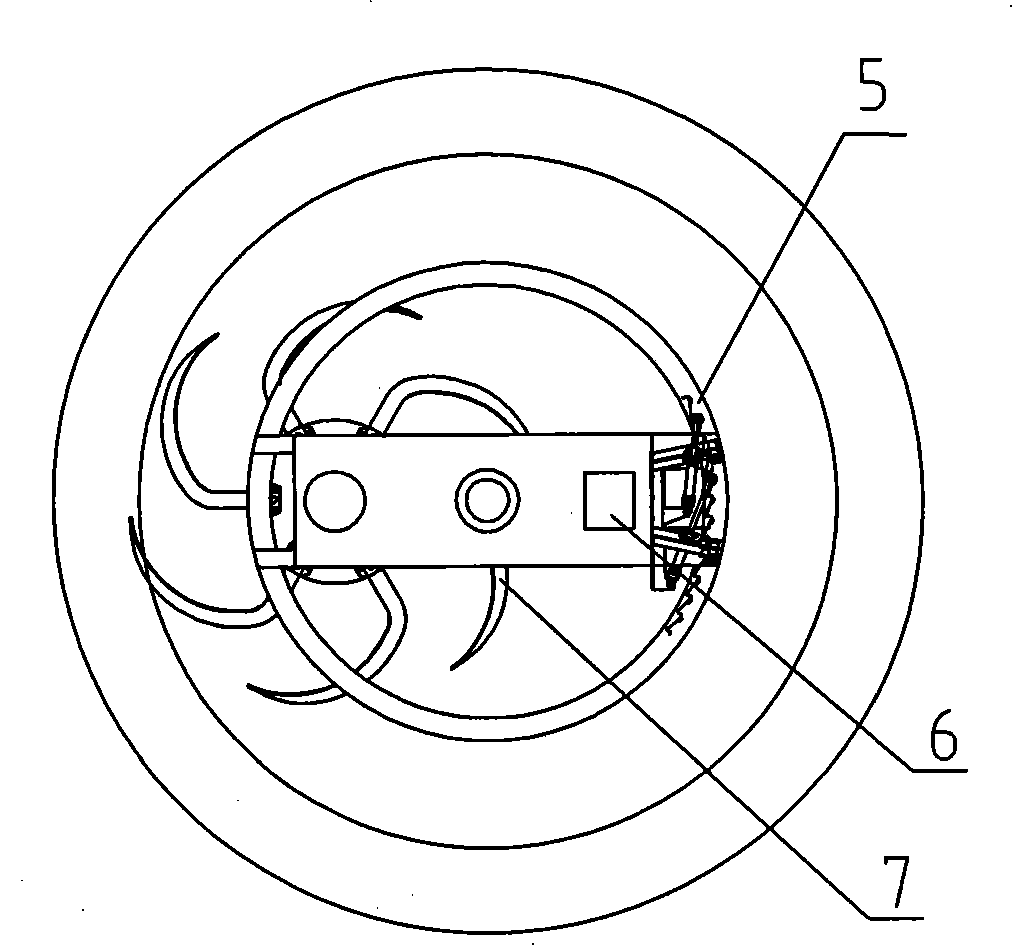

Bulk material silo cutter tooth unloader

The invention relates to a cutter teeth discharging machine of a bulk material silo, which is characterized in that: a slewer is arranged right above a discharging hopper on the bottom of the silo; the slewer is a slewing tray frame slewing around a central shaft; one side of the edge of the slewing disk is provided with a set of hydraulic driving system while the other side thereof is provided with a rotary cutterhead with a speed reduction motor; the cutterhead is provided with one to six cutter teeth and the working surface of the cutter teeth is provided with scrapers; an decompression cone which is used for preventing the material from arching and is supported on the wall of the silo is arranged in the silo right above the slewer. By adopting the discharging machine, whether single-cutter discharging or multi-cutter discharging is adopted can be determined according to storage amount of the bulk material and the size of the silo. The discharging machine has the advantages of flexible layout position of the silo, small labor load for maintenance and environmental protection.

Owner:SINOFINN NEW ENERGY INVESTMENT

Decaisnea insignis seed oil extraction method

InactiveCN103710138AReduce wearFast penetrationFatty-oils/fats productionEngineeringOrganic chemistry

The invention provides a decaisnea insignis seed oil extraction method, wherein the decaisnea insignis seed raw material utilization rate is high, and the extracted decaisnea insignis seed oil has high purity. The extraction method comprises: adopting decaisnea insignis seed as a raw material, carrying out drying, shelling, peeling and crushing on the decaisnea insignis seed, rolling the crushed decaisnea insignis seed, adding water to the obtained rolled billet, steaming, frying until achieving a drying state, and carrying out pressure increase squeezing, precipitation and filtration to obtain the decaisnea insignis seed oil. According to the present invention, the two-stage pressure increase technology is adopted, pre-squeezing is performed under the relatively low pressure, the pressure is increased after completing the pre-squeezing to make the oil yield of the oil material be rapidly increased, and the oil residue rate of the cake meal is reduced, wherein the oil residue of the cake being subjected to two-stage squeezing is less than 3%.

Owner:ANKANG AGRI SCI RES INST

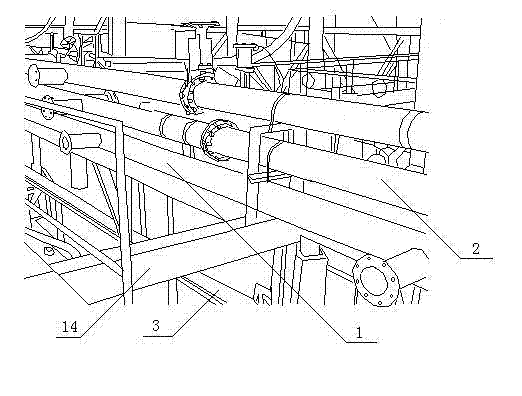

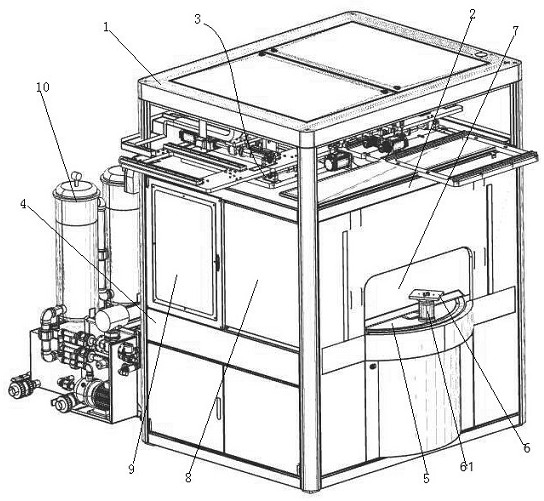

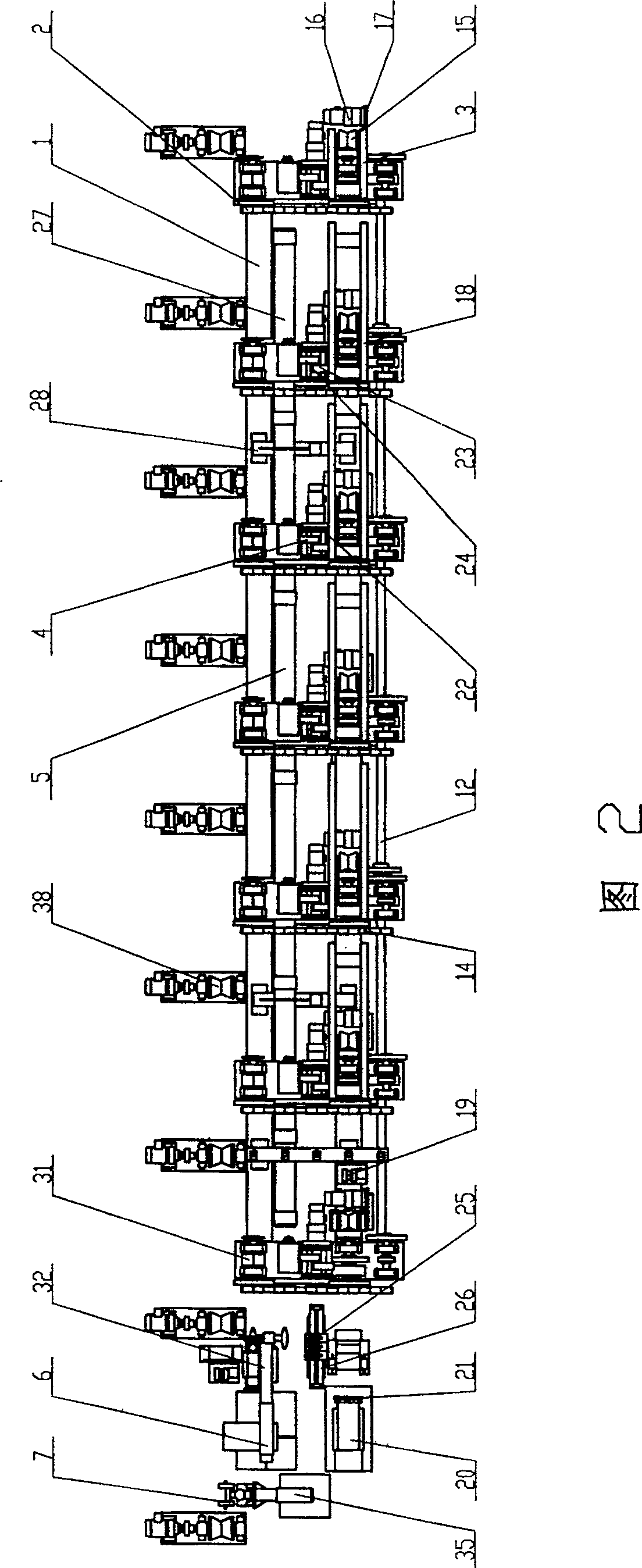

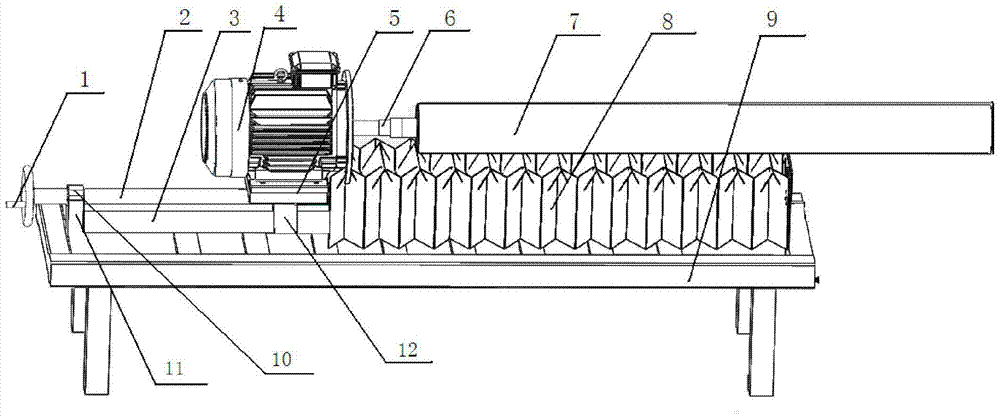

Punched seam sleeve cleaning machine

ActiveCN104550138AImprove working environmentReduce labor intensityHollow article cleaningEngineeringDrive motor

The utility model discloses a punched seam sleeve cleaning machine, comprising a frame; a plurality of support rollers linearly arranged on the frame and used for bearing a punched seam sleeve; a rotation mechanism arranged on the frame and used for driving the punched seam sleeve to rotate; a rotation driving motor fixed on the frame and used for driving the rotation mechanism to rotate; a traveling mechanism arranged on the frame and moving on the frame along the axis direction of the punched seam sleeve; and a wheel brush cleaning mechanism arranged on the traveling mechanism and moving along with the traveling mechanism; the wheel brush cleaning mechanism comprises a cleaning wheel brush and a cleaning motor for driving the cleaning wheel brush to rotate; the cleaning wheel brush is rotated under the driving of the cleaning motor and contacts with the punched seam sleeve to be cleaned. The punched seam sleeve cleaning machine has the characteristics of high efficiency and good cleaning quality.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

Wire hanging rack for vehicle denso production open wire machine

InactiveCN101488649AMeet work speed requirementsConvenience to workLine/current collector detailsCable installation apparatusProduct typeHigh density

The invention discloses a wire-hanging frame of wire openers for vehicular electric fitting production, which is provided with a frame and a wire-hanging structure of the wire-hanging frame (1) and characterized in that the wire-hanging structure is a wire-hanging rod (2) horizontally arranged and the wire-hanging rod (2) is fixedly arranged on the frame of the wire-hanging frame (1). By adopting the wire-hanging frame provided by the technical proposal, enough frame positions are ensured to fully satisfy the working speed requirements of efficient fully-automatic wire openers, a clean and orderly production field and civilized production are realized by hanging wires according to different product types, convenience is brought to operators to put on semi-finished products on shelves by classification, and the work of the workers is more convenient and the working platform becomes more humanized thanks to the added bedplates of the high density plates .

Owner:WUHU TIANHAI ELECTRIC FITTING

Low-resistance and high-efficiency powder concentrator

InactiveCN101653764AImprove powder selection efficiencyIncrease productionEngine sealsGas current separationLarge sizeMachining

The invention discloses a low-resistance and high-efficient powder concentrator which is a novel low-resistance and high-efficiency powder concentrator that is formed by scientifically combining two classification mechanisms together according to vortex classification and inertia centrifugal classification principles on the basis of comprehensively absorbing a classification principle of a third-generation high-efficient powder concentrator in the world and further carrying out improvement and development. The invention has high powder-concentration efficiency, reliable rotor seal, simple structure, small device size, light weight and flexible arrangement, can improve the yield of a mill by a large margin, does not need large-size castings or machining and is convenient for mounting and maintaining.

Owner:HEFEI CEMENT RES DESIGN INST

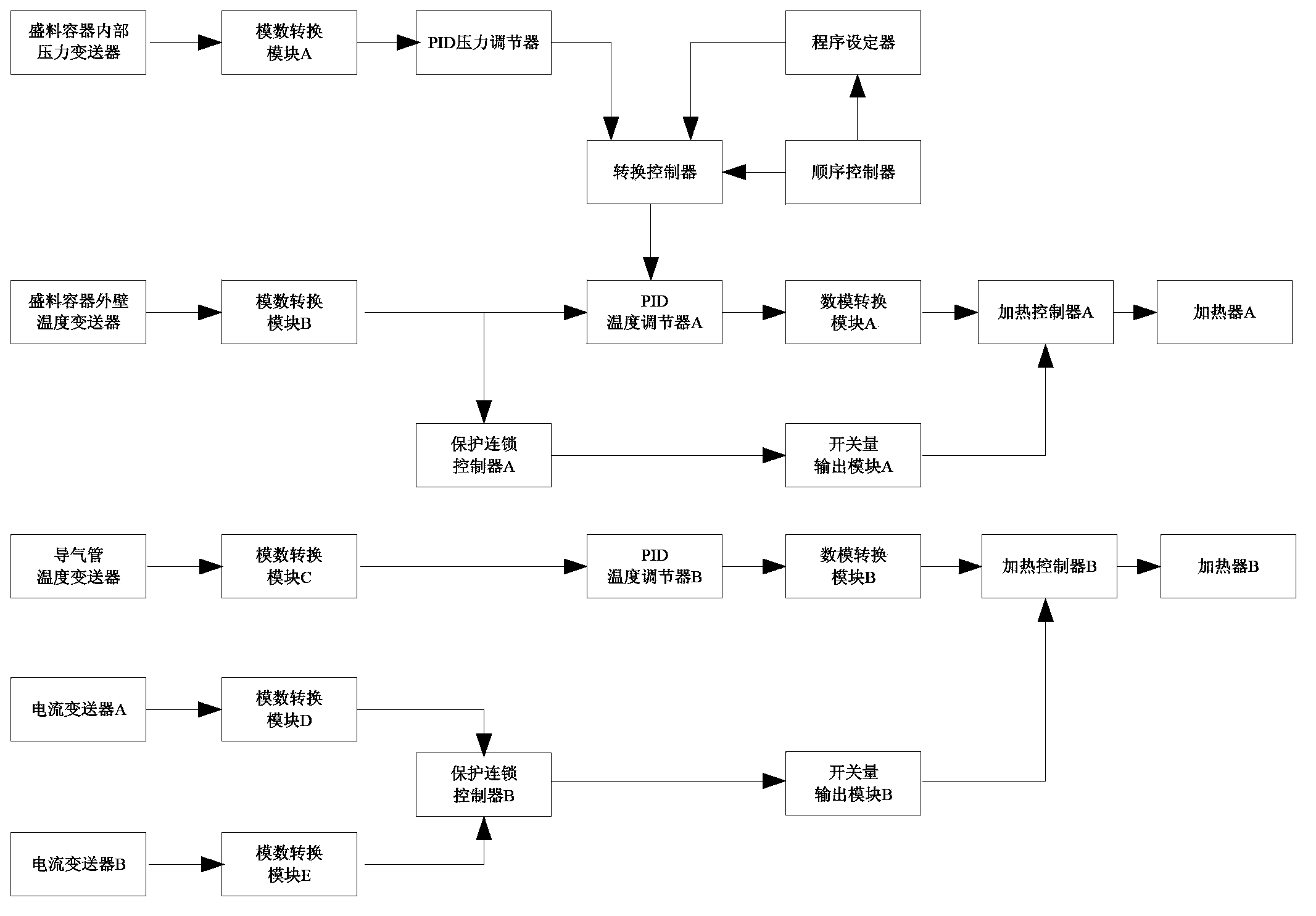

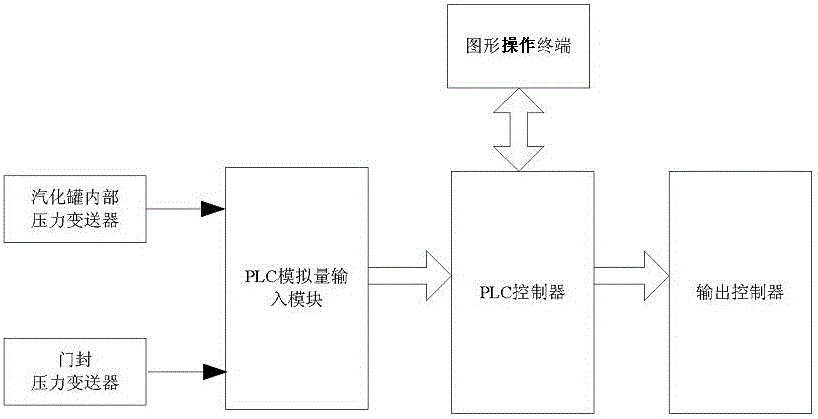

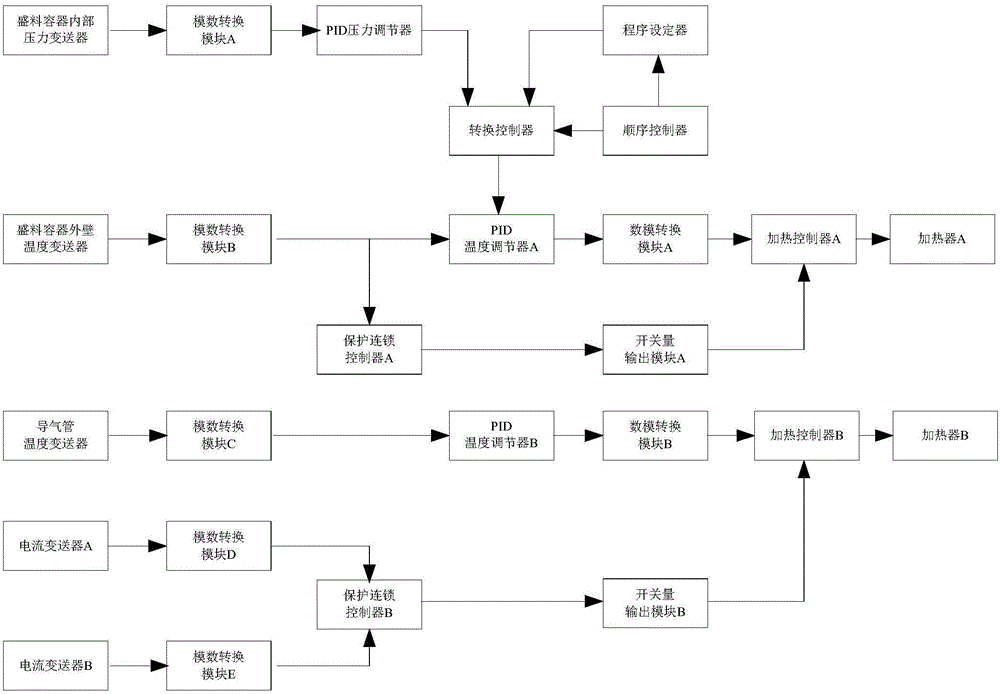

UF6 vaporization automatic control system and control method thereof

ActiveCN103838188AReduce the number of craftsmenReduce labor intensityTotal factory controlProgramme total factory controlAutomatic controlLinkage concept

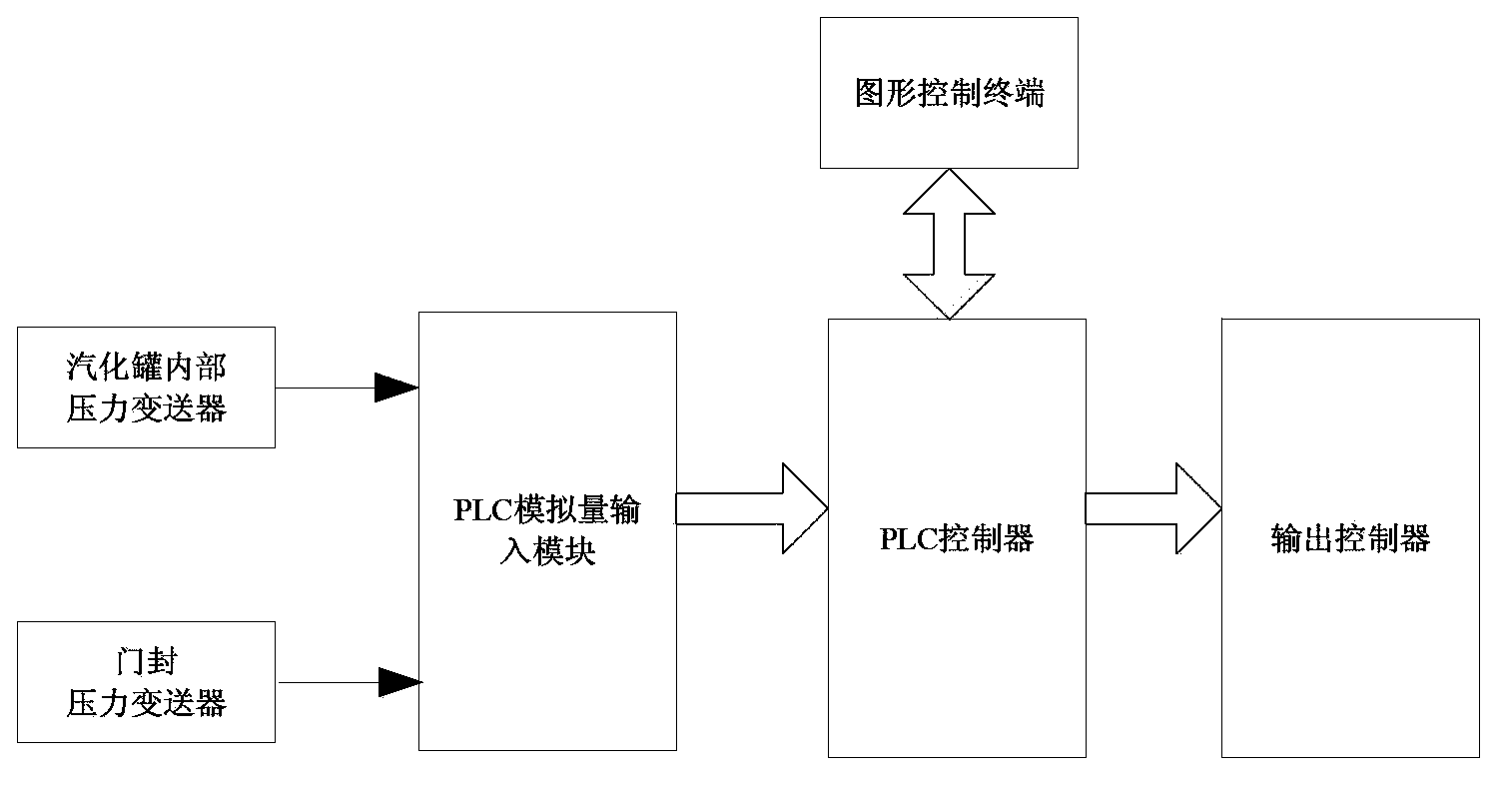

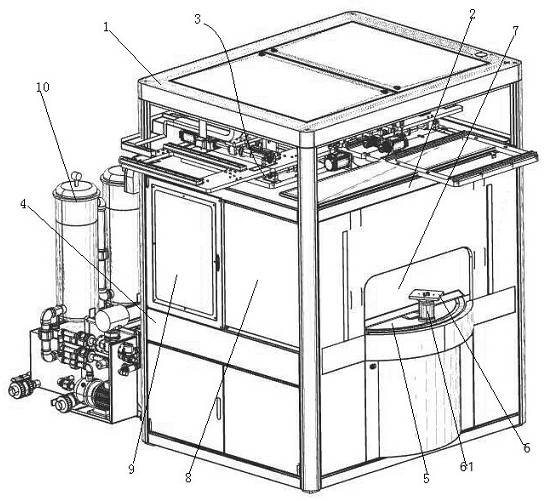

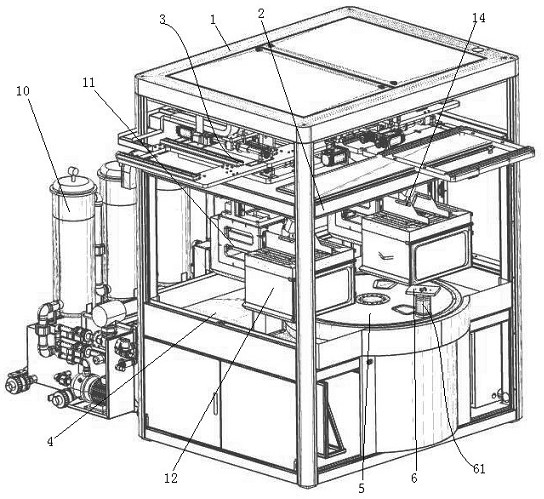

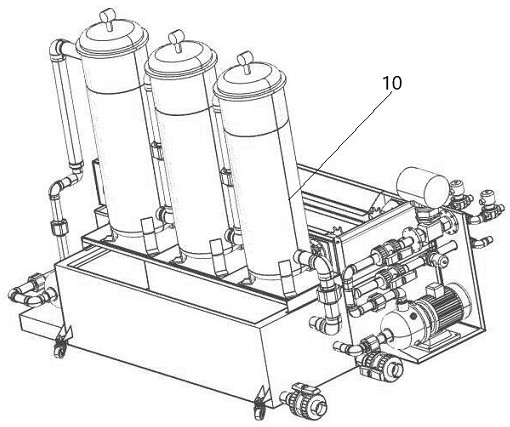

The invention, which belongs to the technical field of automatic controlling, particularly relates to a UF6 vaporization automatic control system and a control method thereof. A DCS control system of the system is composed of a material holding container internal pressure transmitter, a material holding container outer-wall temperature transmitter, a gas-guide tube temperature transmitter, a current transmitter, an analog-to-digital conversion module, a PID pressure regulator, a program setting device, a sequence controller, a conversion controller, a PID temperature regulator A, a PID temperature regulator B, a protection linkage controller, a digital-to-analog conversion module, a switching value output module, a heating controller, and a heater. And a PLC control system of the system includes a vaporization tank internal pressure transmitter, a doorseal pressure transmitter, a PLC analog input module, a PLC controller, a graphic operation terminal, and an output controller. The DCS control system is used for realizing continuous automatic control and protection of the internal pressure and the wall temperature of the material holding container as well as continuous and automatic control and protection of the gas-guide tube temperature and the heater current; and the PLC control system is used for realizing automatic control and protection of the internal pressure and the doorseal pressure of the vaporization tank.

Owner:CNNC JIANZHONG NUCLEAR FUEL

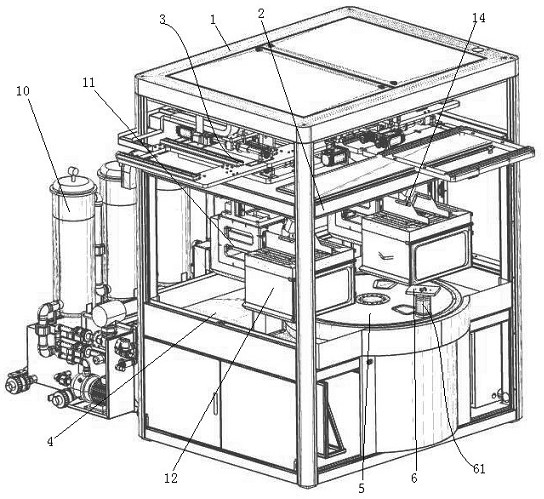

Numerical control double-station polishing machine

ActiveCN111941249AClean and orderly production environmentSuitable working environmentPolishing machinesGrinding machinesNumerical controlCircular disc

The invention discloses a numerical control double-station polishing machine and relates to the field of polishing equipment. Two position adjusting mechanisms are arranged on a supporting frame in amachine box and connected with a polishing machine head; a polishing mechanism is arranged on the polishing machine head; a protection device is connected to the lower end of the polishing machine head; a wax adding device is arranged at the upper end of the protection device; a workbench is arranged below the supporting frame; a rotary disc and a disc driving mechanism are arranged on the workbench; three workpiece stations are arranged on the rotary disc; a jig mounting table and a workpiece rotating mechanism are arranged on each workpiece station; trimming knife devices are arranged on thetwo sides of the rotary disc; a water curtain fixing frame is arranged on the sides, away from the rotary disc, of the trimming knife devices; a water curtain mechanism is arranged on the water curtain fixing frames; the water curtain mechanism is connected with a water circulation device; the machine box is provided with an automatic lifting door and a side door; and an automatic lifting curtainis arranged between the side door and the water curtain fixing frame. Dust generated by polishing is captured by the water curtain mechanism and is filtered and recycled by the water circulation device, so that a production environment is clean and orderly, and a proper working environment is created.

Owner:东莞市尚弘博实业有限公司

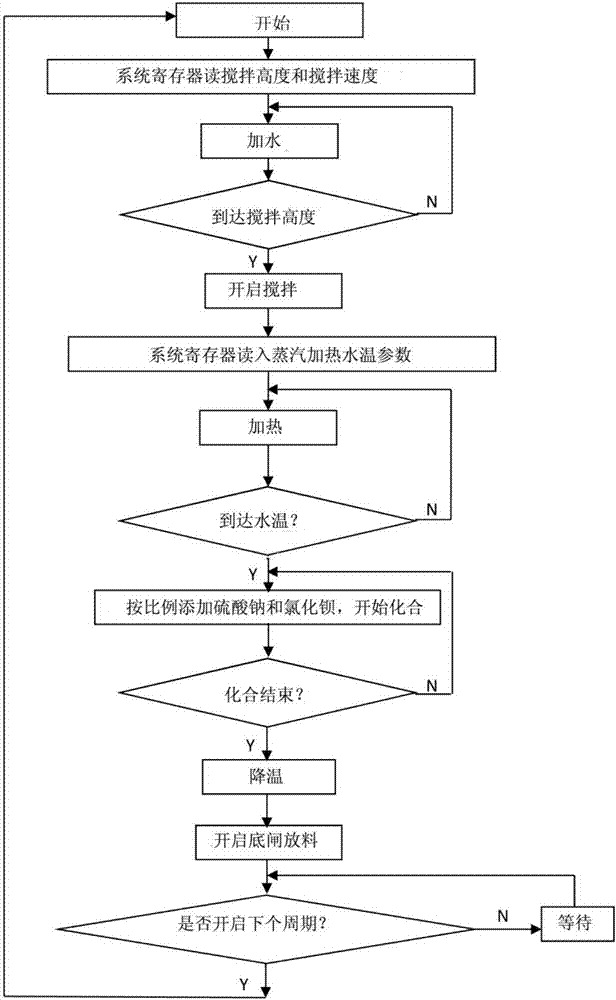

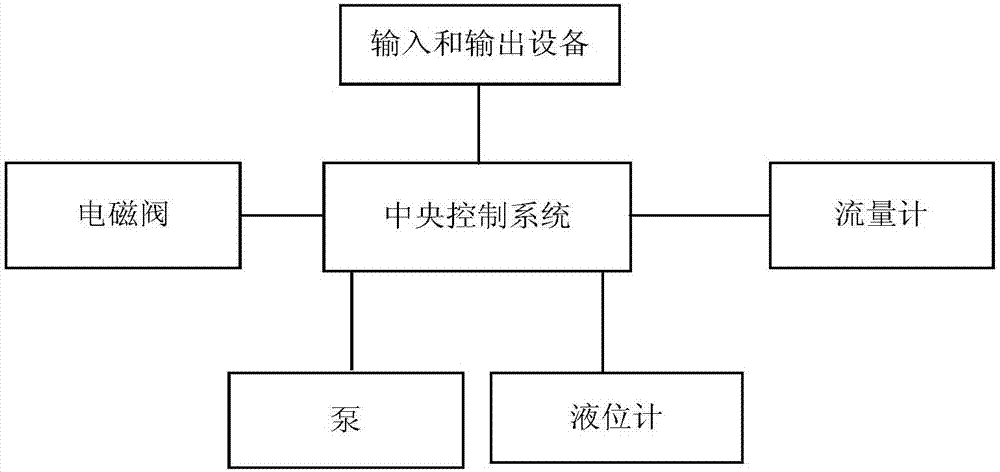

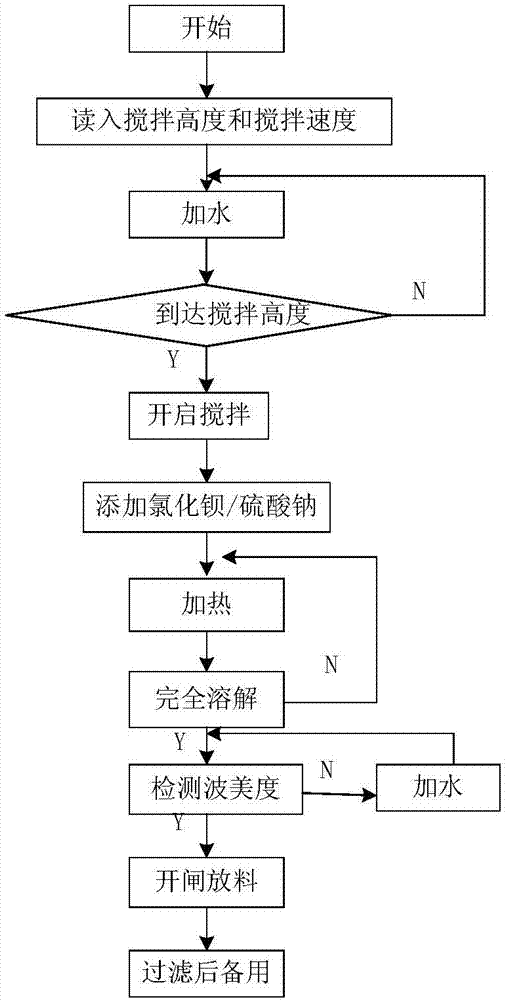

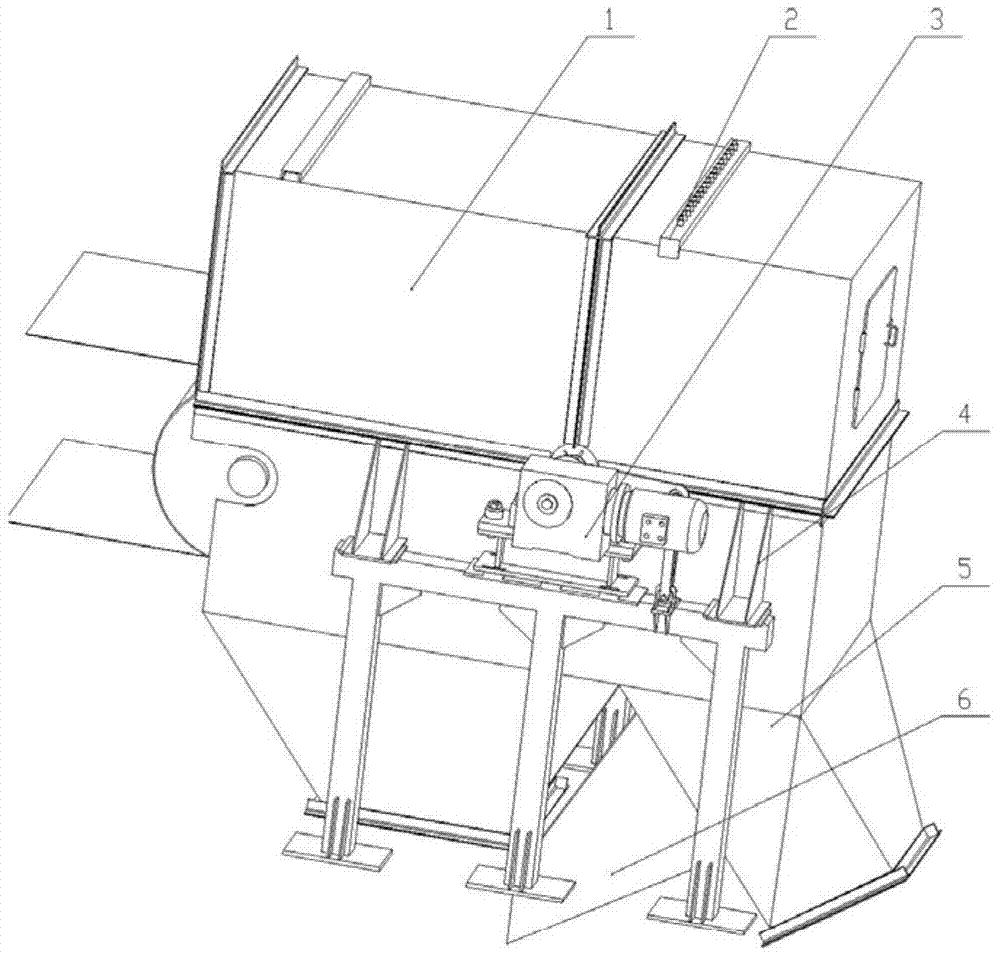

Automatic control production process for medicinal barium sulfate

ActiveCN106966421AImprove pass rateGuaranteed one pass rateCalcium/strontium/barium sulfatesEnergy inputSulfate radicalsAutomatic control

The invention relates to the technical field of barium sulfate synthesis, in particular to an automatic control production process for medicinal barium sulfate. The process includes: a central control system sends a production instruction to start a cold water pump for pumping drinking water into a chemical combination tank; when the water level reaches a 1 / 7-1 / 4 position of the chemical combination tank, a stirrer starts, and a steam valve starts to heat; when the water temperature reaches 60-80 DEG C, a feeding valve starts, and barium chloride solution and sodium sulfate solution equal in quantity are pumped into the chemical combination tank from a barium solution storage tank and a nitrate solution storage tank at the same time to realize chemical combination; when a set flow rate is achieved, feeding stops, chemical combination is finished, sampling for detecting particle size and reaction endpoints is performed to guarantee slight excessiveness of sulfate radicals, the central control system sends an instruction, a bottom gate of the chemical combination tank opens, and an automatic delivery device delivers materials to a pressure filter. By adoption of the automatic control production process, one-time qualification rate of barium sulfate synthesis is greatly increased, product quality is guaranteed, and cost is reduced.

Owner:青岛红蝶新材料有限公司

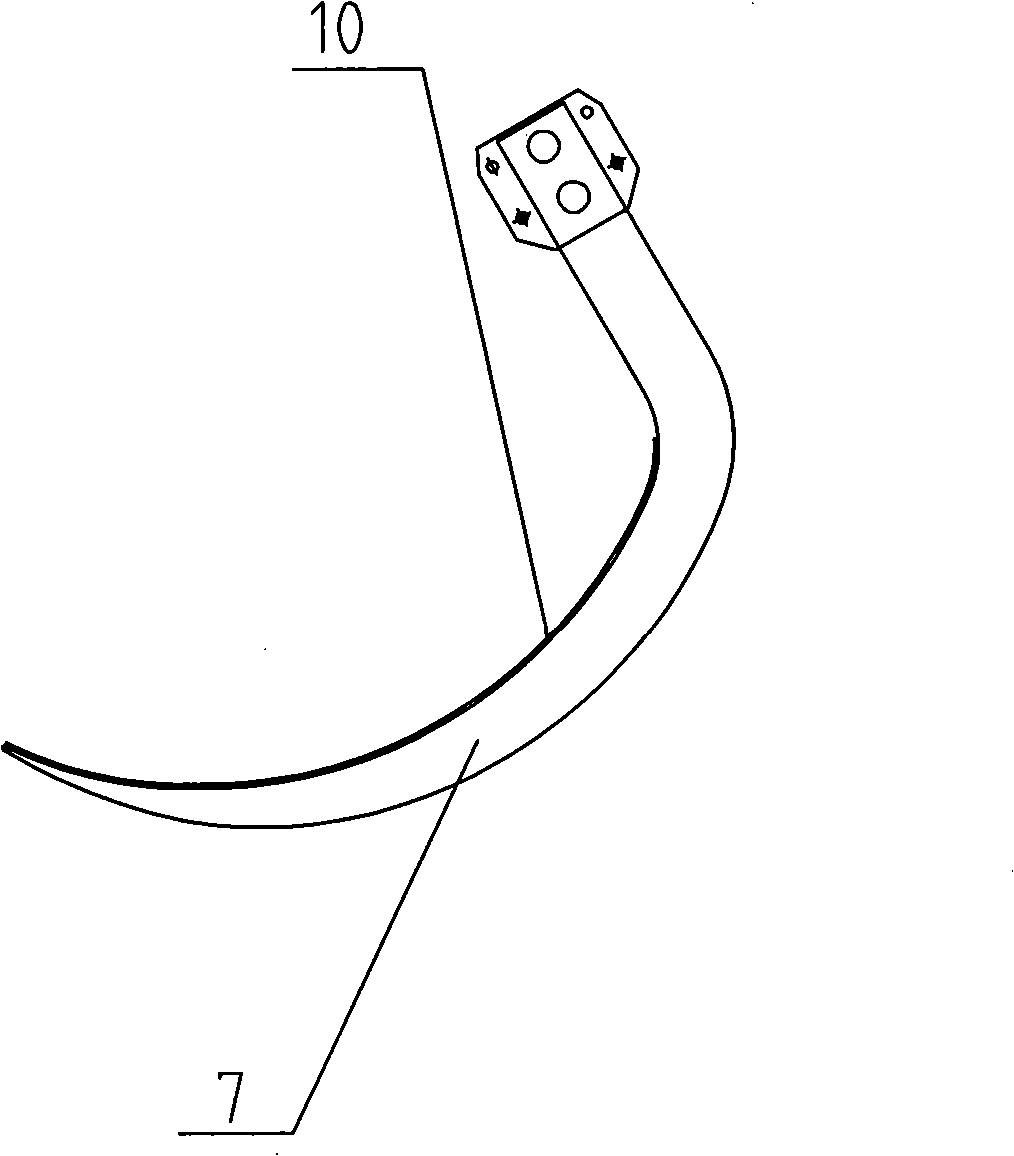

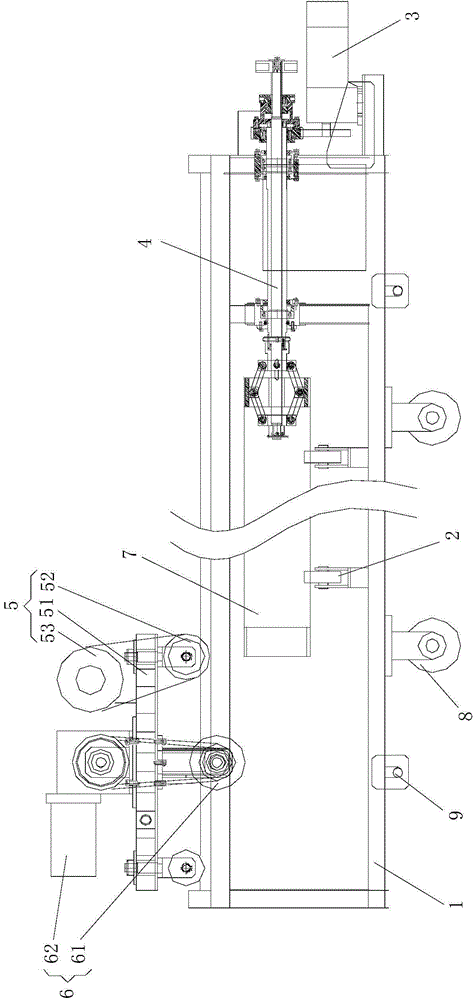

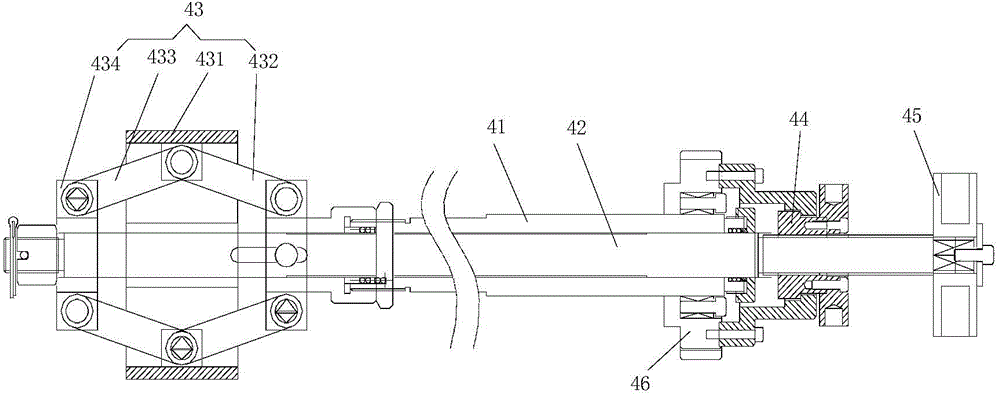

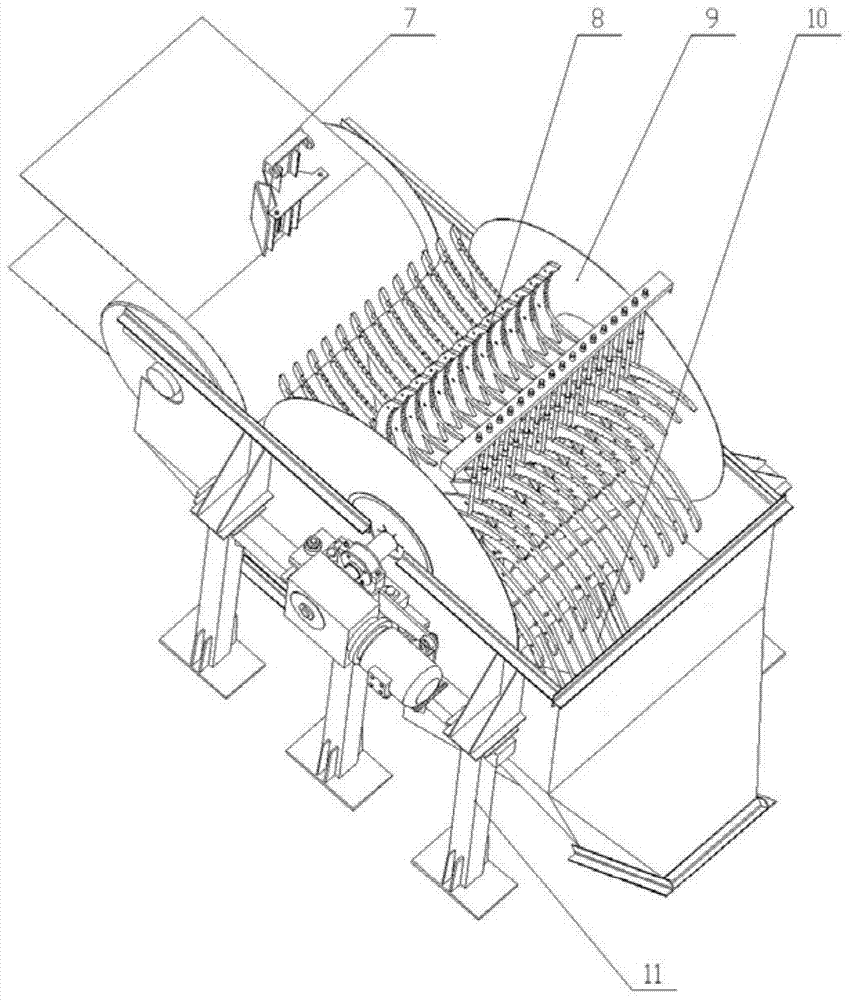

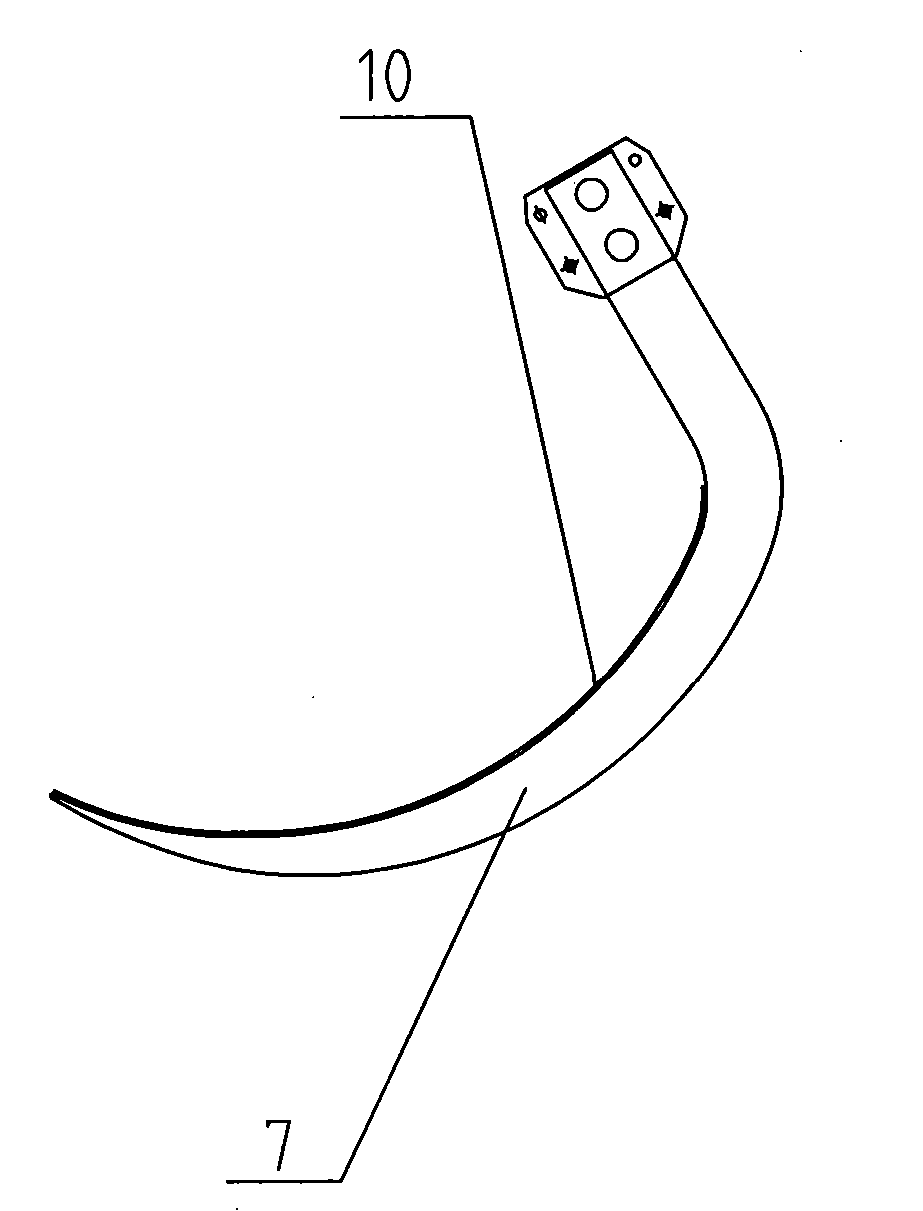

Single-tooth claw pricking type sundries removing device

InactiveCN103861815AAvoid direct incinerationRealize civilized productionGradingEngineeringMechanical engineering

The invention relates to a single-tooth claw pricking type sundries removing device. The single-tooth claw pricking type sundries removing device comprises a box body assembly, a comb assembly, a driving device assembly, a supporting seat body, a sundries collection hopper, a material recovery hopper, a coal plowing body, single-teeth claw pricking separation bodies, material baffles, an elastic vibrating recovery grate and two supporting legs, wherein the material baffles are respectively arranged at the two ends of a driving roller of the driving device assembly in the box body assembly; the single-teeth claw pricking separation bodies are arranged on the driving roller of the driving device assembly and are spirally arranged in a staggered way; the elastic vibrating recovery grate is arranged below the driving roller of the driving device assembly and is fixedly arranged on the inner side of the sundries collection hopper; the comb assembly is hung above a box body of the box body assembly and between sickle-shaped single teeth which are stereoscopically distributed in a staggered way on comb teeth of the comb assembly at positions for inserting the single-tooth claw pricking separation bodies. Since the single-tooth claw pricking separation bodies are used for separating conveying medium, the elastic vibrating recovery grate performs secondary recovery to sundries and the comb assembly sweeps the single-tooth claw pricking separation bodies to remove the sundries, civilized production is realized.

Owner:洛阳广盈机械设备有限公司

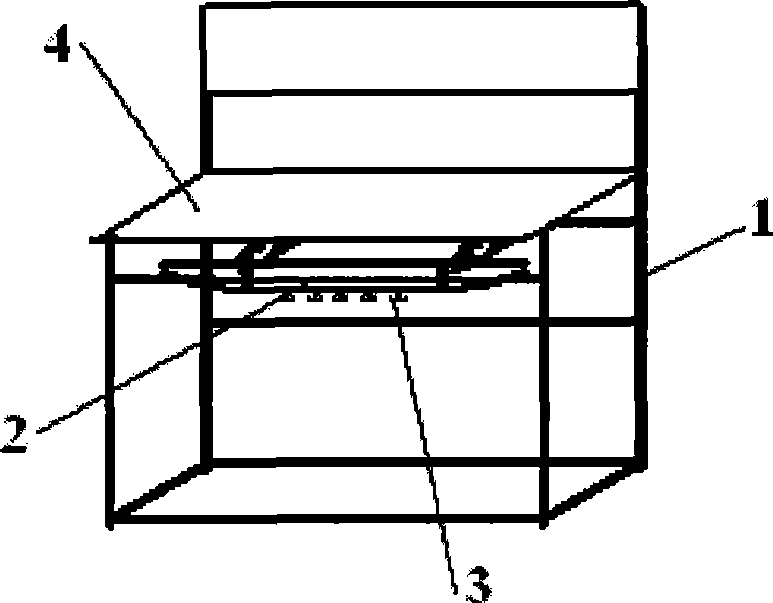

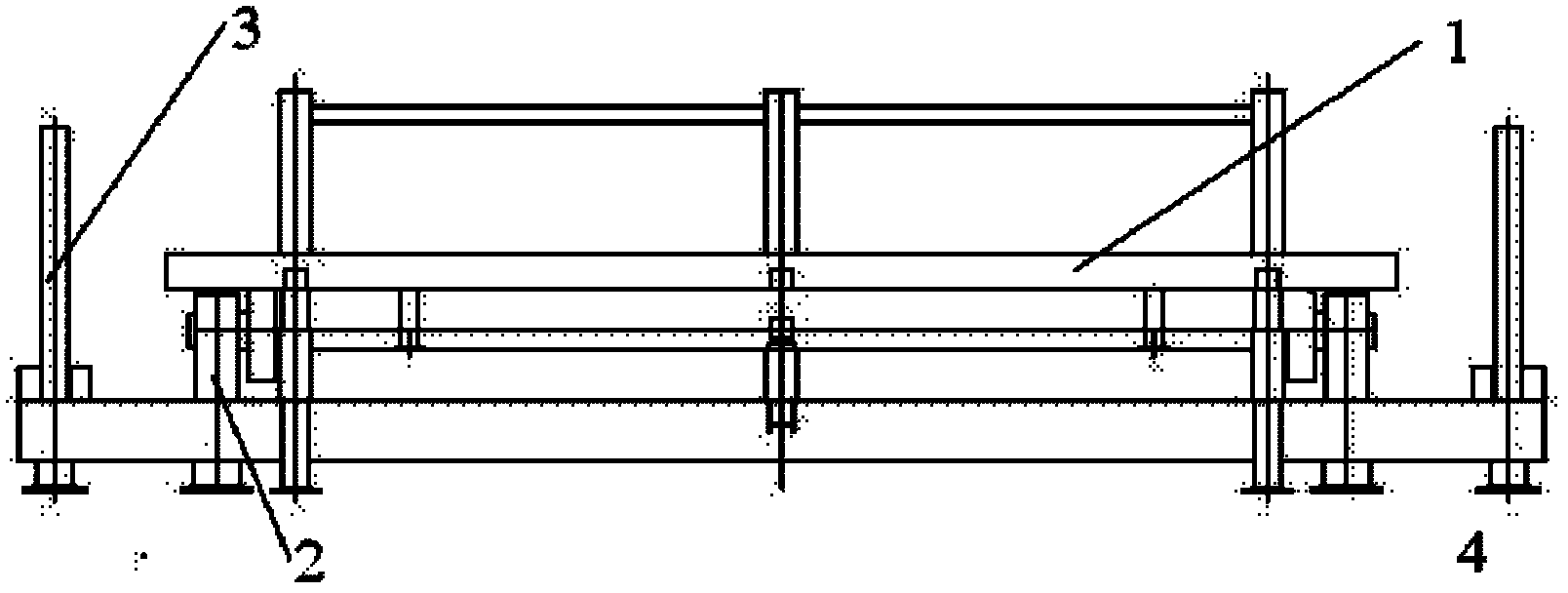

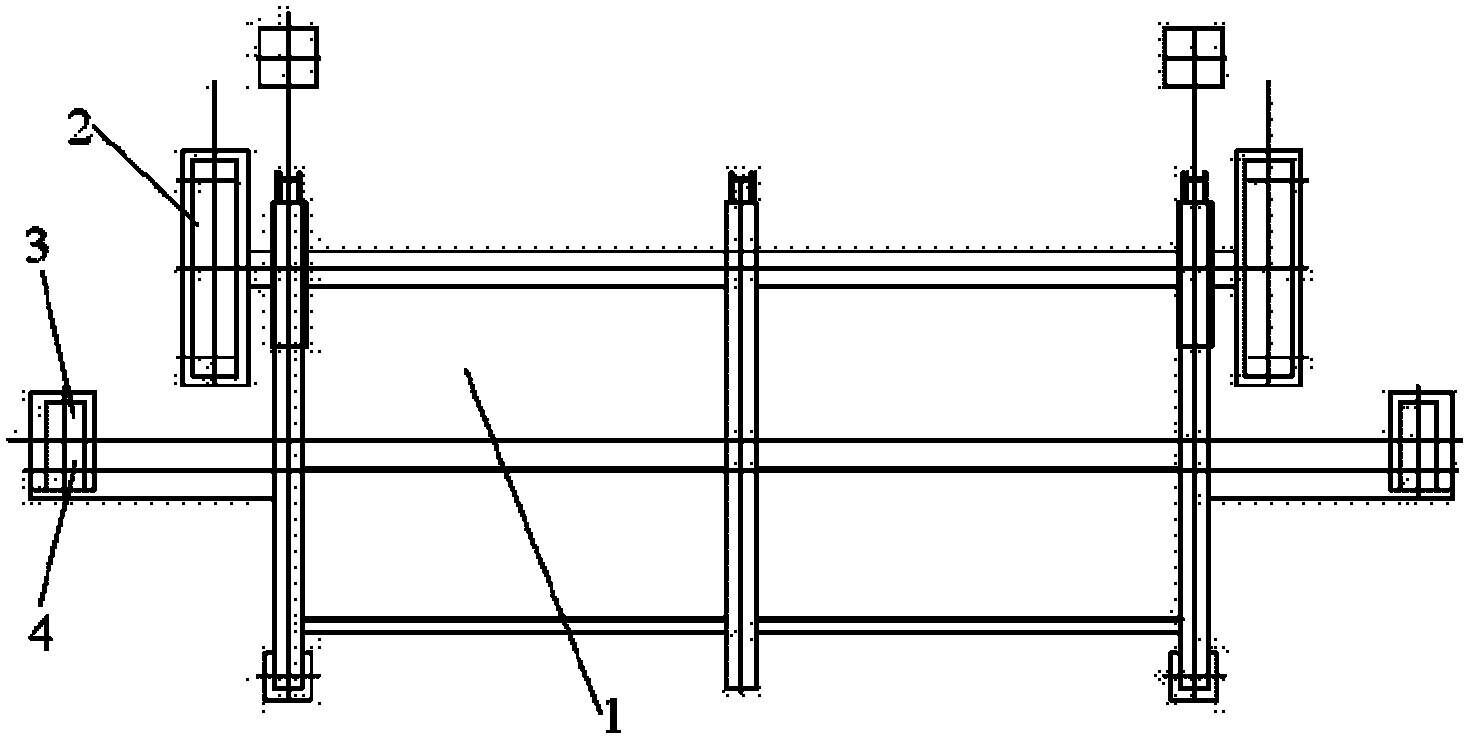

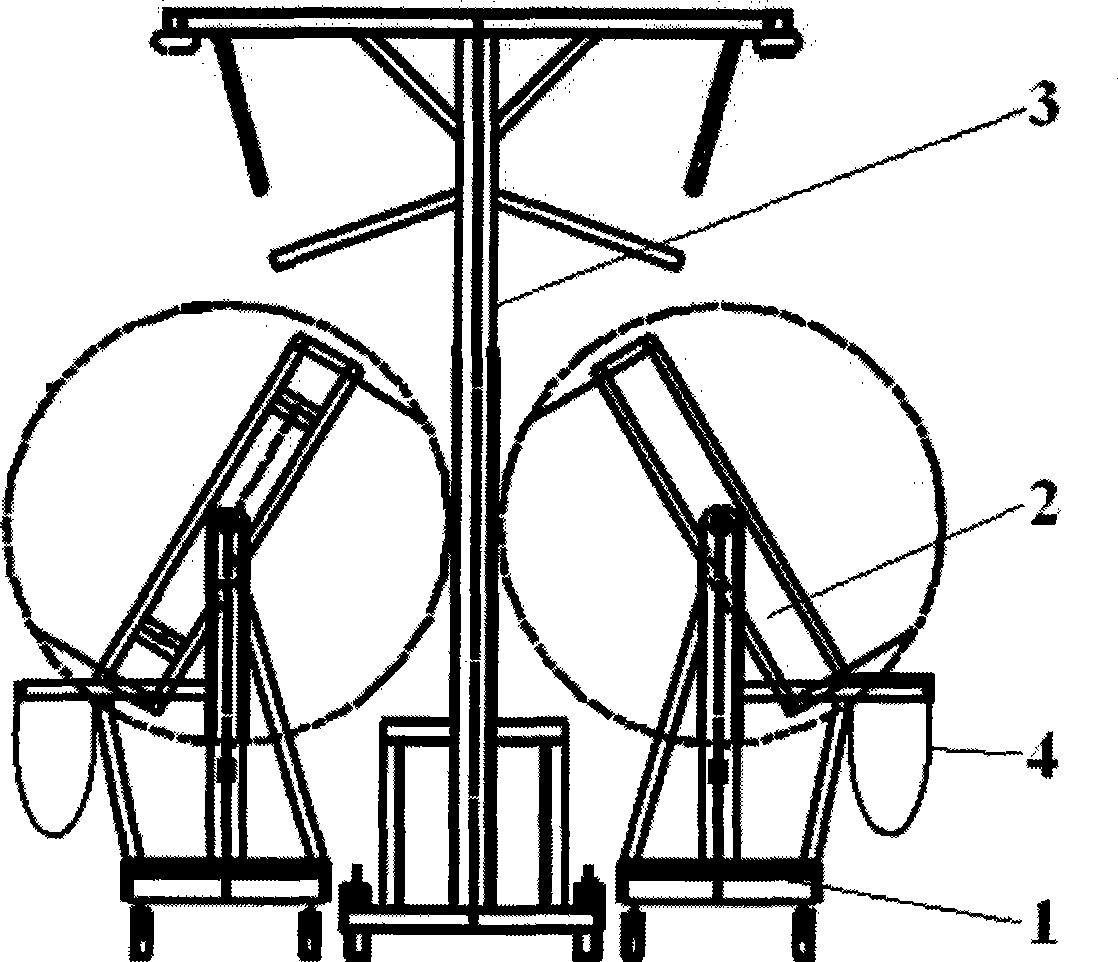

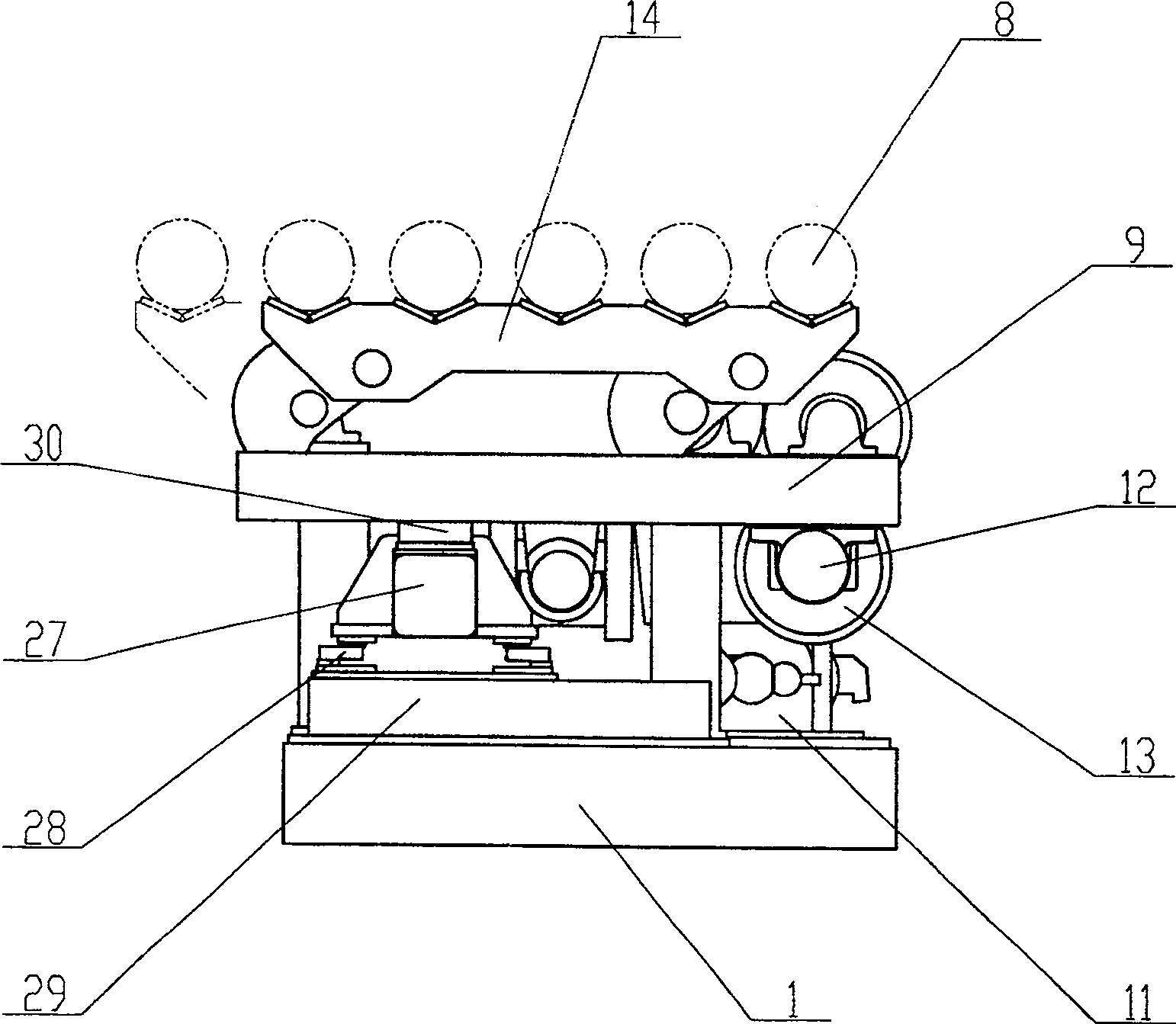

Overturning table in concrete manufacturing equipment

InactiveCN102310476AReasonable arrangementTakes up little work spaceCeramic shaping apparatusWork performanceEngineering

The invention discloses an overturning table in concrete manufacturing equipment, which comprises an overturning table (1), support frames (2) of the overturning table and overturning hydraulic devices (3), wherein the overturning hydraulic devices (3) are connected with the overturning table (1) through a rotating shaft (4); and hydraulic cylinders (3) of each overturning hydraulic device (3) are arranged outside the two ends of each support frame (2) of the overturning table. Due to the adoption of the technical scheme, the layout of the equipment is more reasonable and compact, the occupied working space is smaller, the reliability of the working performance is higher, the ground of the equipment is kept clean, the service life of the equipment is prolonged, and civil production is realized.

Owner:WUHU SUREMAKER MACHINERY

Low-resistance and high-efficiency powder concentrator

InactiveCN101653764BImprove powder selection efficiencyIncrease productionEngine sealsGas current separationLarge sizeMachining

The invention discloses a low-resistance and high-efficient powder concentrator which is a novel low-resistance and high-efficiency powder concentrator that is formed by scientifically combining two classification mechanisms together according to vortex classification and inertia centrifugal classification principles on the basis of comprehensively absorbing a classification principle of a third-generation high-efficient powder concentrator in the world and further carrying out improvement and development. The invention has high powder-concentration efficiency, reliable rotor seal, simple structure, small device size, light weight and flexible arrangement, can improve the yield of a mill by a large margin, does not need large-size castings or machining and is convenient for mounting and maintaining.

Owner:HEFEI CEMENT RES DESIGN INST

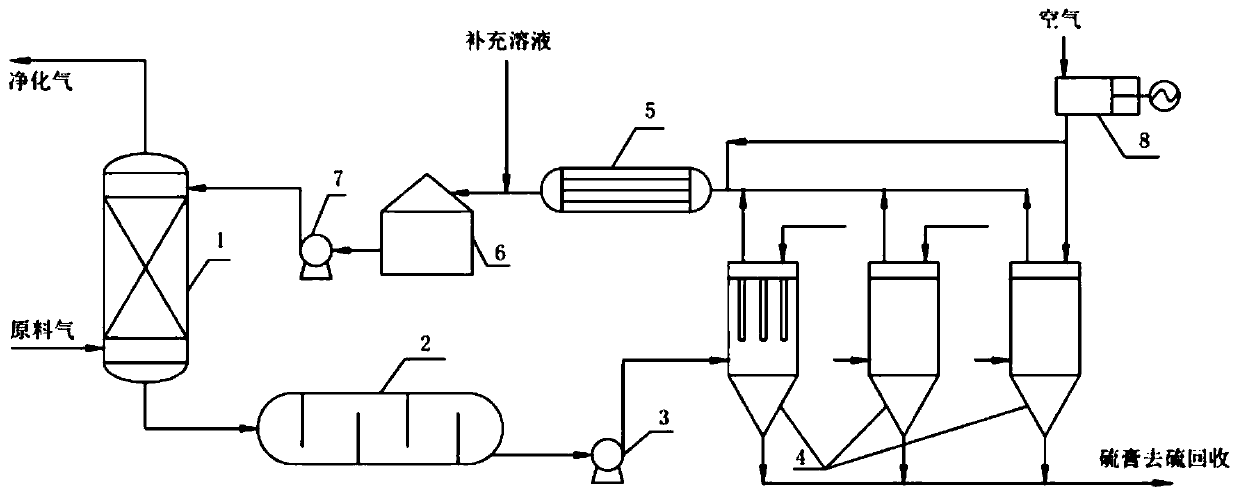

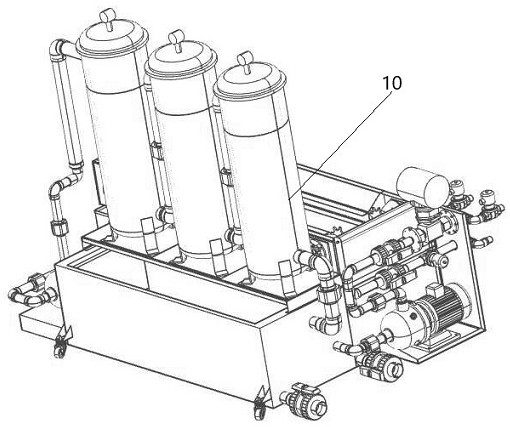

Energy-saving regeneration method for wet oxidation desulfurization process

InactiveCN111001294ALow Suspended SulfurReduce resistanceGas treatmentWater contaminantsPtru catalystProcess engineering

The invention discloses an energy-saving regeneration method for a wet oxidation desulfurization process. According to the method, sulfur particles in a pregnant solution are separated by integrated membrane filters, and when the resistance drop of an integrated membrane element of an integrated membrane separator is increased to a designed value, the integrated membrane element is reversely blownby using compressed gas so as to recover the resistance drop of the integrated membrane element to an original value. The multiple integrated membrane filters are connected in parallel, during normaloperation, one integrated membrane filter is in a blowback regeneration state, the other integrated membrane filters are in a filtering state, and the switching process between filtering and blowbackis controlled automatically or manually. When the barren liquor discharged from the filter and compressed air are mixed and then the mixture passes through a static reactor, the desulfurization catalyst in the barren liquor is regenerated due to the action of oxygen in a short time. The method has the characteristics of low barren liquor suspension sulfur, small absorption liquid circulation amount, low power consumption, small excess air coefficient, small secondary salt generation amount and low raw material consumption. Full-closed full-automatic control can be achieved, and the operationenvironment is good. In a word, the method is an energy-saving green technology.

Owner:西安润川环保科技有限公司

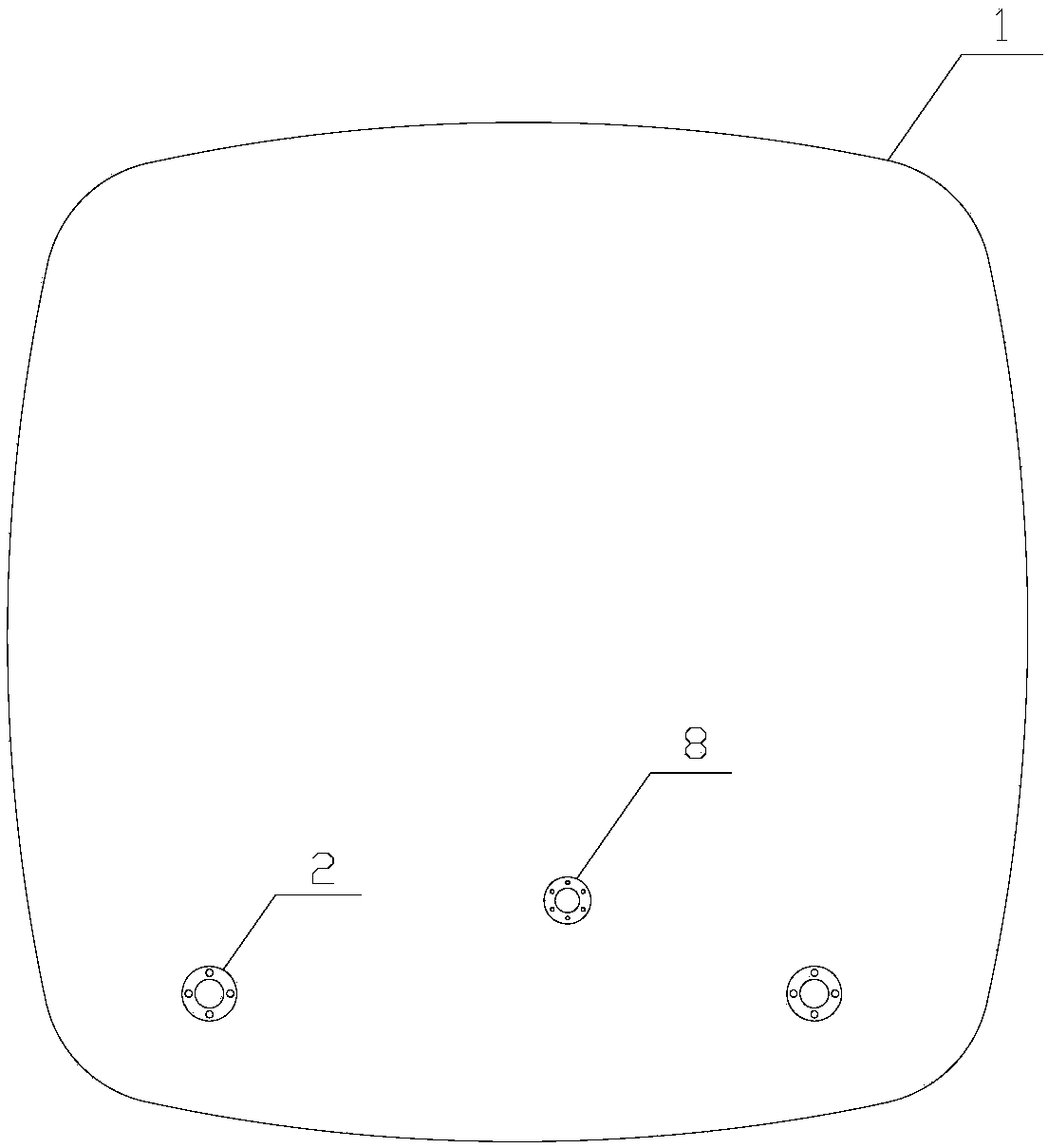

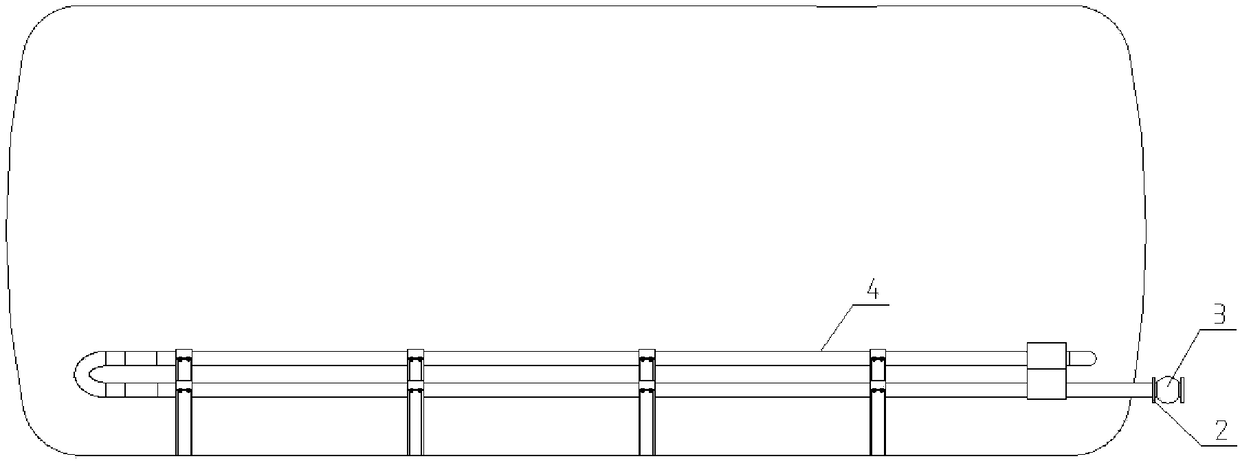

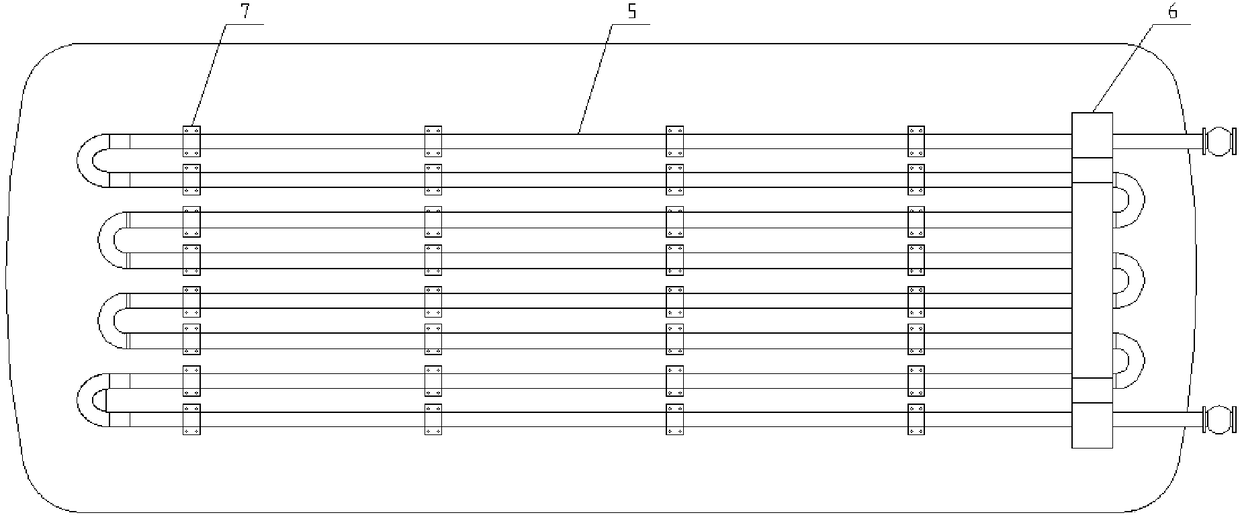

Asphalt tank container heating system

The invention relates to an asphalt tank container heating system, and solves the problems of low efficiency in a traditional asphalt tank container heating mode and coking and aging caused by highertemperature of local asphalt due to nonuniform distribution of a temperature field, radiated by flame, of a fire pipe. The heating system comprises a tank body, a heat conducting oil inner discharge pipe module, a heat conducting oil access port valve and a heat conducting oil furnace module; the heat conducting oil inner discharge pipe module comprises an inner discharge pipe, a discharge pipe end support table and a discharge pipe bracket; the discharge pipe bracket is fixedly arranged in the tank body; the inner discharge pipe is arranged on the discharge pipe bracket; the discharge pipe end support table fixedly supports an access port of the inner discharge pipe; the access port of the inner discharge pipe is provided with a connecting flange; the connecting flange is connected with the heat conducting oil access port valve; the heat conducting oil furnace module comprises an electric control cabinet, a circulating oil pump, a heat conducting oil heating furnace, a high oil tank,a heat conducting oil outlet and a heat conducting oil inlet; and the oil conducting oil access port valve is respectively connected with the heat conducting oil outlet and the heat conducting oil inlet of the heat conducting oil furnace module through arranged metal hoses.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Phenol-free resin for offset printing ink and preparation method thereof

InactiveCN102226059BReduce pollutionReduce the impact on physical healthInksNatural resin chemical modificationPerformance indexFatty acid

The invention provides a phenol-free resin for offset printing ink. The resin formula comprises, by weight, 60-80 parts of rosin, 1-10 parts of fumaric acid, 1-10 parts of maleic anhydride, 1-10 parts of aliphatic acid, 10-20 parts of polyol, and 0.1-1 part of a catalyst. The performance indexes of the phenol-free resin for offset printing ink are as follows: the viscosity is 15000-25000 mPa.s / 25DEG C; the release property is larger than or equal to 5 ml / 2g; the acid value is less than or equal to 25 mgKOH / g; and the softening point is 160-175 DEG C. The invention also provides a method for preparing the phenol-free resin for offset printing ink. The effects of the invention are as follows: the phenol-free resin for offset printing ink can be used for offset printing ink; there exists no phenolic substance and formaldehyde during the reaction process, thus minimizing the atmospheric pollution and the harmfulness to the health of an operator and realizing civilized production.

Owner:TIANJIN CITY TIANNING RESIN

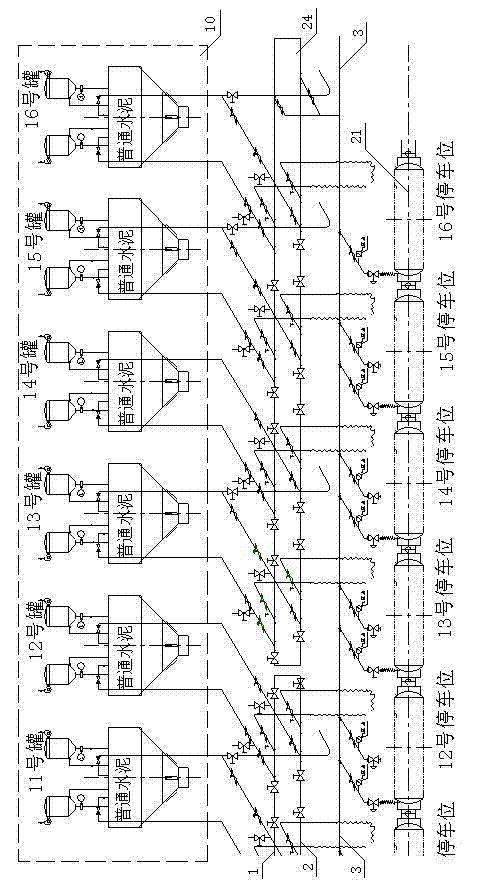

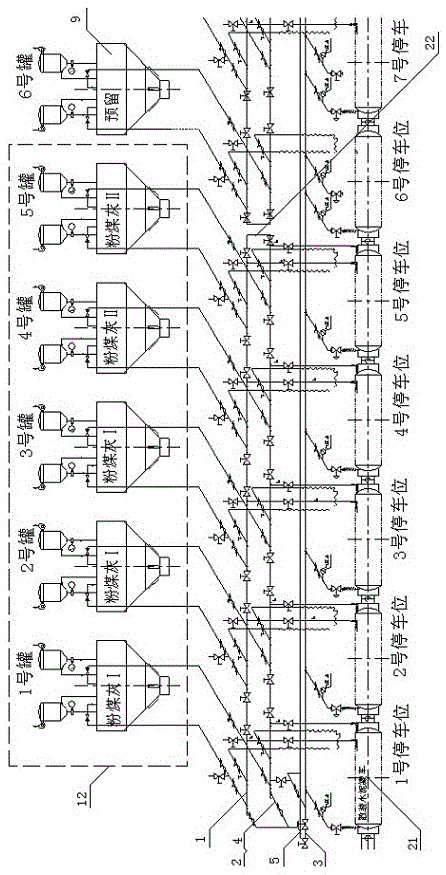

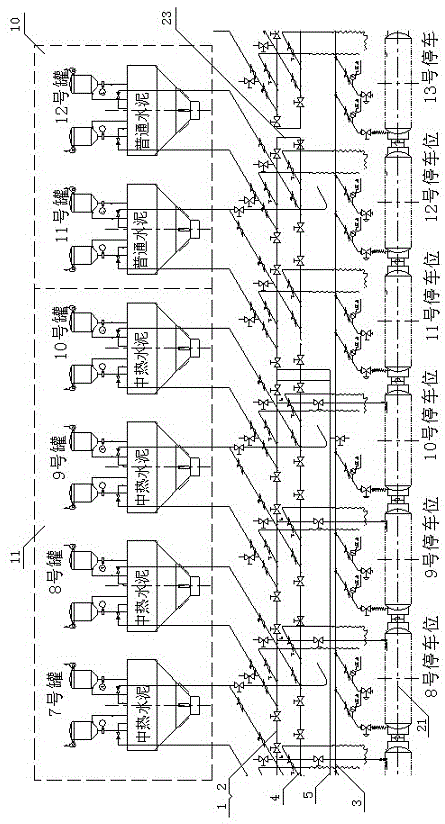

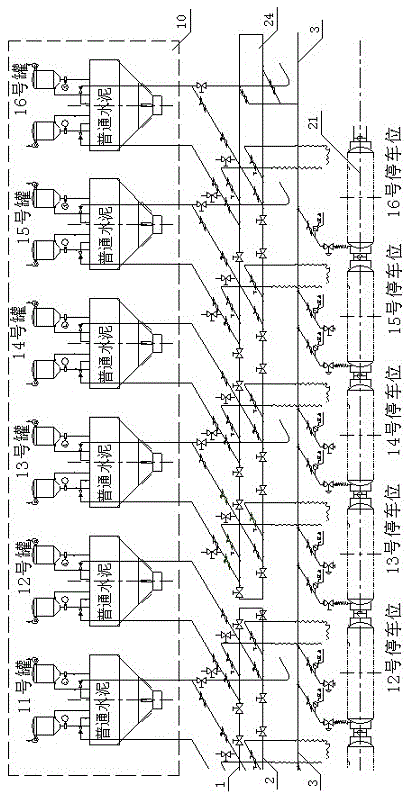

Loose-packed gel material parallel ash-unloading system

The invention relates to the technical field of transportation, in particular to a loose-packed gel material parallel ash-unloading system for transfer management of a loose-packed gel material in large hydropower station construction. The system comprises 1) a loose-packed gel material storage tank, 2) a main pipeline system, 3) an ash unloading branch pipe, 4) an ash loading branch pipe, and 5) a warehouse side unloading port. According to the loose-packed gel material loading system, an advanced computer remote management mode is adopted, and the routine work in the conventional loose-packed gel material loading system is changed from an optional manual mode into a normalized computer work mode, which means the revolution of the working mode. According to the loose-packed gel material loading system of the hydropower station, unattended or less-attended operation is realized in a unique way, the work load of maintenance staff is lightened, and the maintenance level is improved. The capability of the loose-packed gel material loading system of a gel material transfer station is greatly improved, and the requirements on peak annual loose-packed gel materials of hydropower stations at all levels are met.

Owner:中国水利水电第四工程局有限公司第六分局

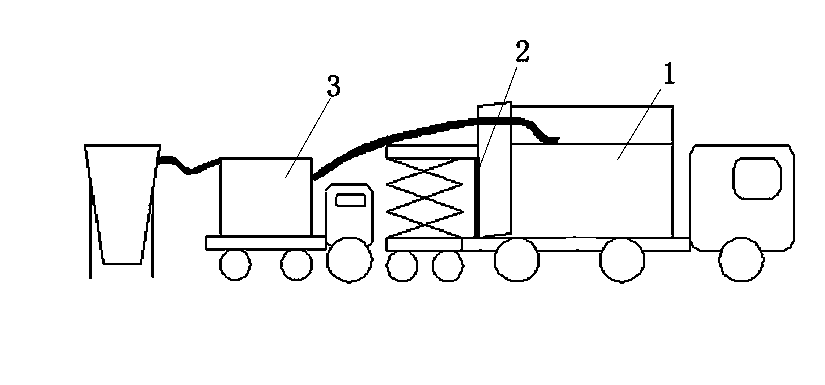

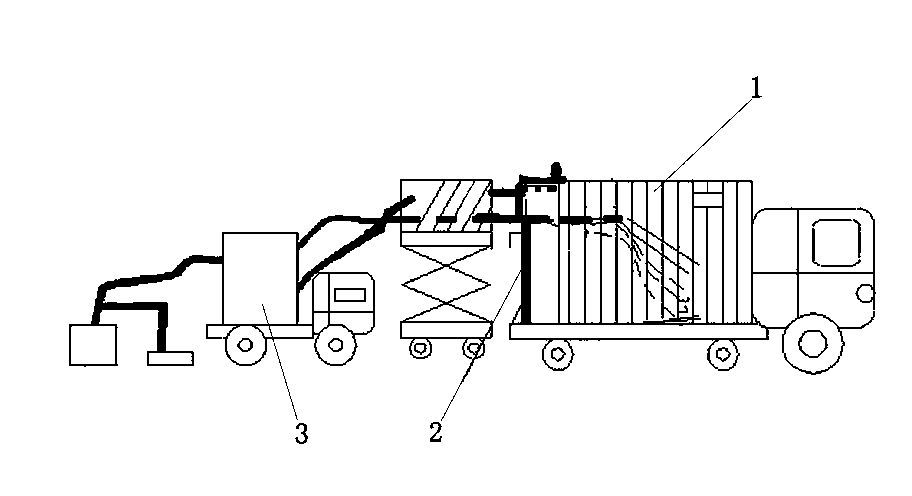

Method for suiting container to load bulk cargoes

Disclosed is a method for suiting a container to load bulk cargoes. A packing method includes the steps: sucking in powder and particle materials from a storage site by a suction nozzle of a pneumatic suction conveyor; and feeding the materials into the container by a connecting hose under the action of the suction conveyor, leading out gas and then removing dust or feeding the materials into the container after taking the materials by a screw conveyor. An unstuffing method includes the steps: sucking out the powder and particle materials from the container by the suction nozzle of the pneumatic suction conveyor; and directly feeding the materials into a storage tank, leading out the gas and then removing the dust or taking the materials by the screw conveyor and the suction conveyor. According to the characteristics of more sites, small quantity and poor packing conditions of small and medium-sized enterprises, a movable and variable tool is designed, the method is wider in practicability, and a trolley is used for bearing the devices. If the loading and unloading quantity is large, a fixed device can be used to decrease investment.

Owner:王马达

Bulk material silo cutter tooth unloader

The invention relates to a cutter teeth discharging machine of a bulk material silo, which is characterized in that: a slewer is arranged right above a discharging hopper on the bottom of the silo; the slewer is a slewing tray frame slewing around a central shaft; one side of the edge of the slewing disk is provided with a set of hydraulic driving system while the other side thereof is provided with a rotary cutterhead with a speed reduction motor; the cutterhead is provided with one to six cutter teeth and the working surface of the cutter teeth is provided with scrapers; an decompression cone which is used for preventing the material from arching and is supported on the wall of the silo is arranged in the silo right above the slewer. By adopting the discharging machine, whether single-cutter discharging or multi-cutter discharging is adopted can be determined according to storage amount of the bulk material and the size of the silo. The discharging machine has the advantages of flexible layout position of the silo, small labor load for maintenance and environmental protection.

Owner:SINOFINN NEW ENERGY INVESTMENT

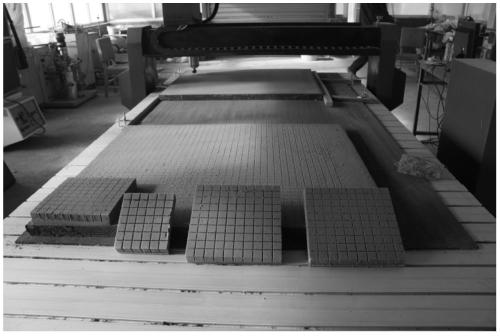

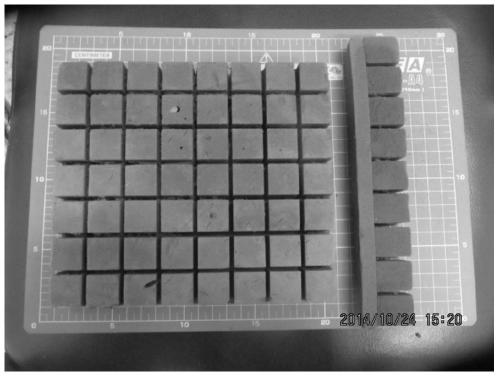

Degradable foam composition for growing seedlings or flower arrangement and its manufacturing method and application

The invention relates to the field of plant cultivation media, and particularly provides a degradable foam composition for seedling raising or flower arrangement. The degradable foam composition for seedling raising or flower arrangement is prepared from the following raw materials: phenol and polyformaldehyde in a mole ratio of 1:(1.4-2.5), water (24mL for every mole of phenol), urea (accounting for 10-25 wt% of the phenol), pulp board (accounting for 6-15 wt% of the phenol), starch (accounting for 6-15 wt% of the phenol), and 10 wt% polyvinyl alcohol (accounting for 2-15 wt% of the phenol). The invention also provides a preparation method and application of the degradable foam composition for seedling raising or flower arrangement. The reaction speed of the preparation method is greatly higher than that of the traditional method, and no wastewater is generated in the whole process. The free formaldehyde content and free phenol content of the prepared product are lower than the national standard, so the product is completely harmless; and the seedling raising container or flower mud prepared from the degradable foam composition is suitable for demands of plants for physical properties of the nutrient and medium.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

uf 6 Vaporization automatic control system and control method

ActiveCN103838188BImprove continuityAchieve protectionTotal factory controlProgramme total factory controlSequence controlAutomatic control

The invention, which belongs to the technical field of automatic controlling, particularly relates to a UF6 vaporization automatic control system and a control method thereof. A DCS control system of the system is composed of a material holding container internal pressure transmitter, a material holding container outer-wall temperature transmitter, a gas-guide tube temperature transmitter, a current transmitter, an analog-to-digital conversion module, a PID pressure regulator, a program setting device, a sequence controller, a conversion controller, a PID temperature regulator A, a PID temperature regulator B, a protection linkage controller, a digital-to-analog conversion module, a switching value output module, a heating controller, and a heater. And a PLC control system of the system includes a vaporization tank internal pressure transmitter, a doorseal pressure transmitter, a PLC analog input module, a PLC controller, a graphic operation terminal, and an output controller. The DCS control system is used for realizing continuous automatic control and protection of the internal pressure and the wall temperature of the material holding container as well as continuous and automatic control and protection of the gas-guide tube temperature and the heater current; and the PLC control system is used for realizing automatic control and protection of the internal pressure and the doorseal pressure of the vaporization tank.

Owner:CNNC JIANZHONG NUCLEAR FUEL

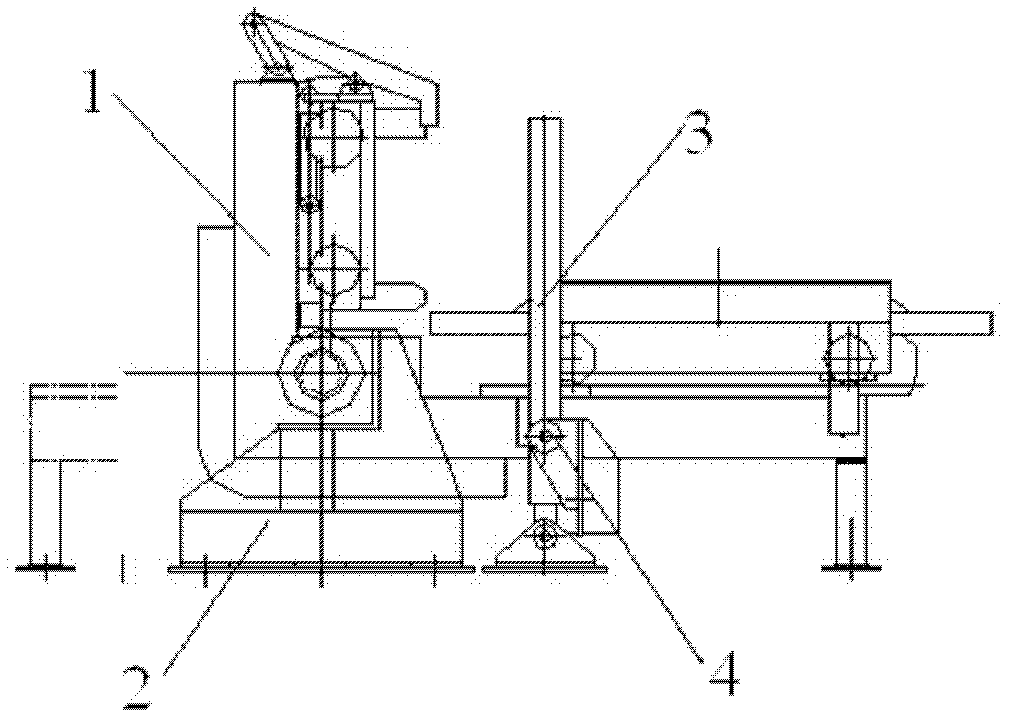

Automobile electric fitting production line

The invention discloses an automobile electrical assembly production line, which comprises a production line fixing frame (3), a production line mobile frame (1) and an electrical assembly operating panel (2) arranged on the production line mobile frame (1) through a rotating shaft, and a cloth pocket (4) is arranged at a position on the production line fixing frame (3) under the electrical assembly operating panel (2) and extending to the operator direction. By adopting the technical proposal, the automobile electrical assembly production line can effectively prevent a lead wire and a terminal from mopping the floor when in production line assembly, lead electrical assembly parts such as the lead wire, and the like not to be damaged in the assembly, and ensure the product quality in technical performances. In addition, the production environment of processing places is also improved, and civilized production is realized.

Owner:WUHU TIANHAI ELECTRIC FITTING

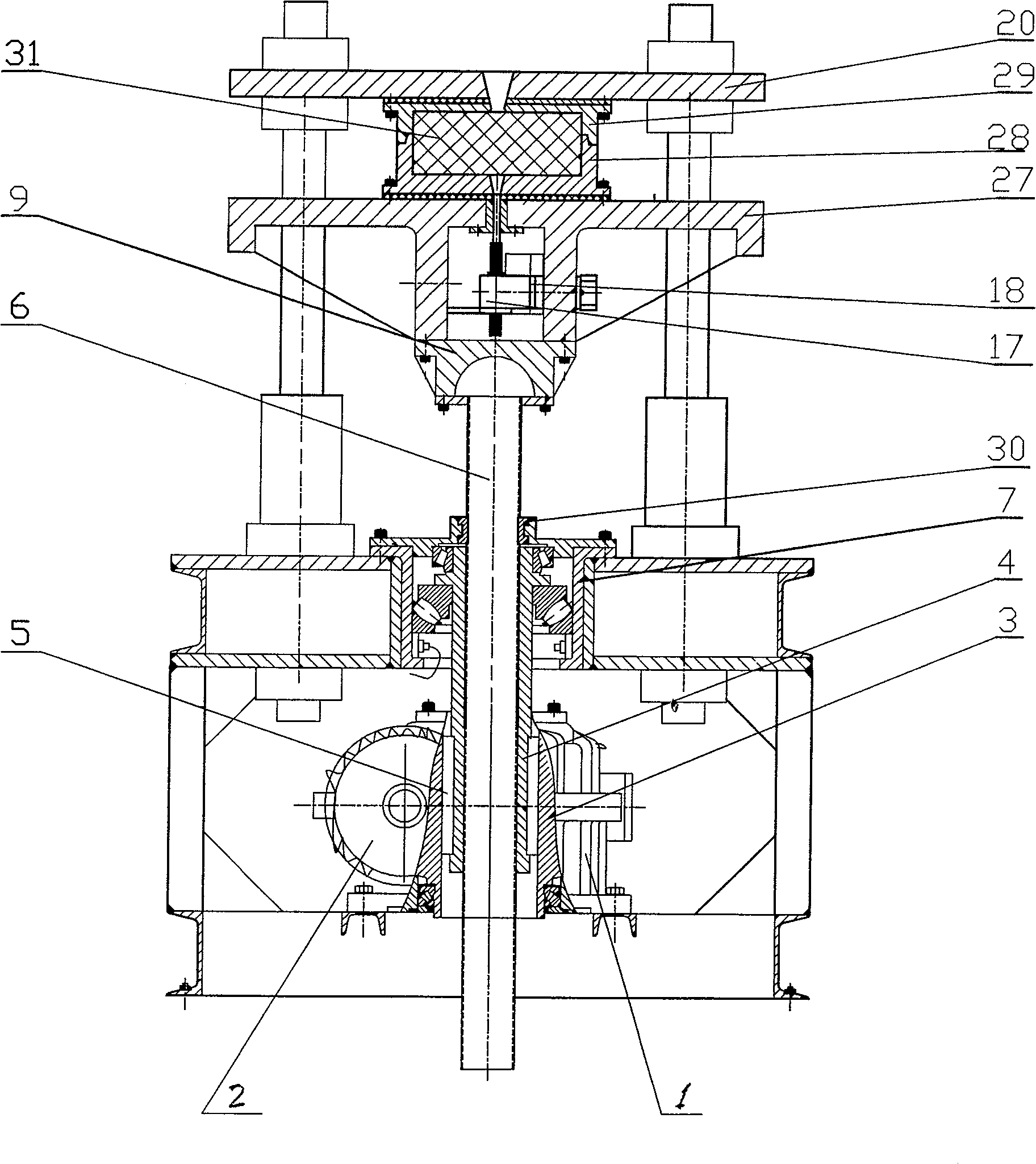

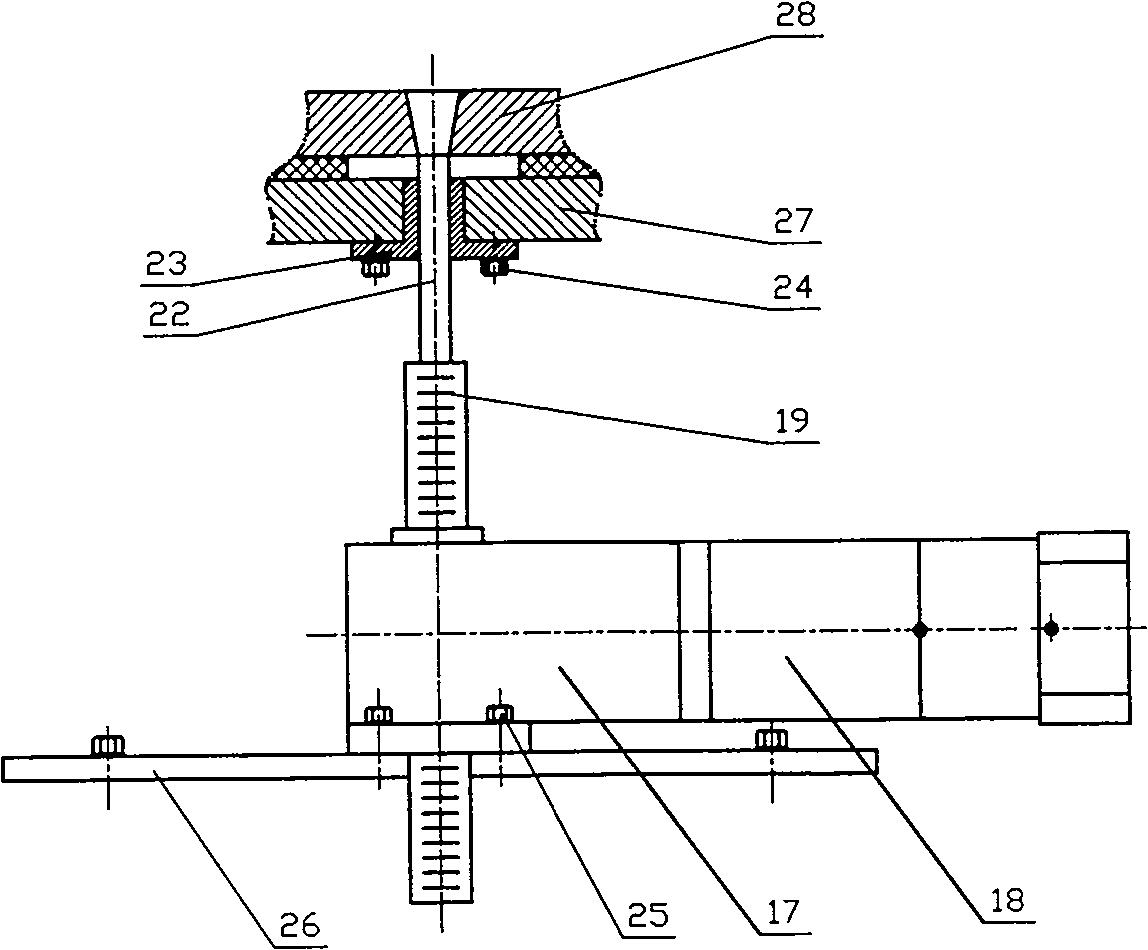

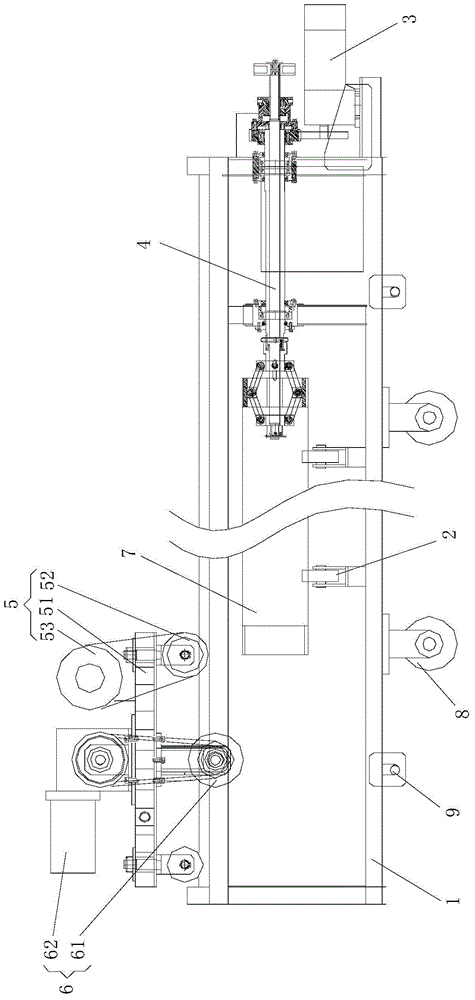

Full electrodynamic mould locking device of rubber injection machine

A full-electric mould locking unit for rubber injector is composed of an electric screw drive system consising of speed reducer and dual-speed motor, a bearing case and an eelctric demoulding unit. A main scrwe connected with the movable mould plate is engaged with a long cylindrical drive nut in the inner hole of a hollow output shaft of speed reducer for locking or opening the mould.

Owner:QINGDAO UNIV OF SCI & TECH

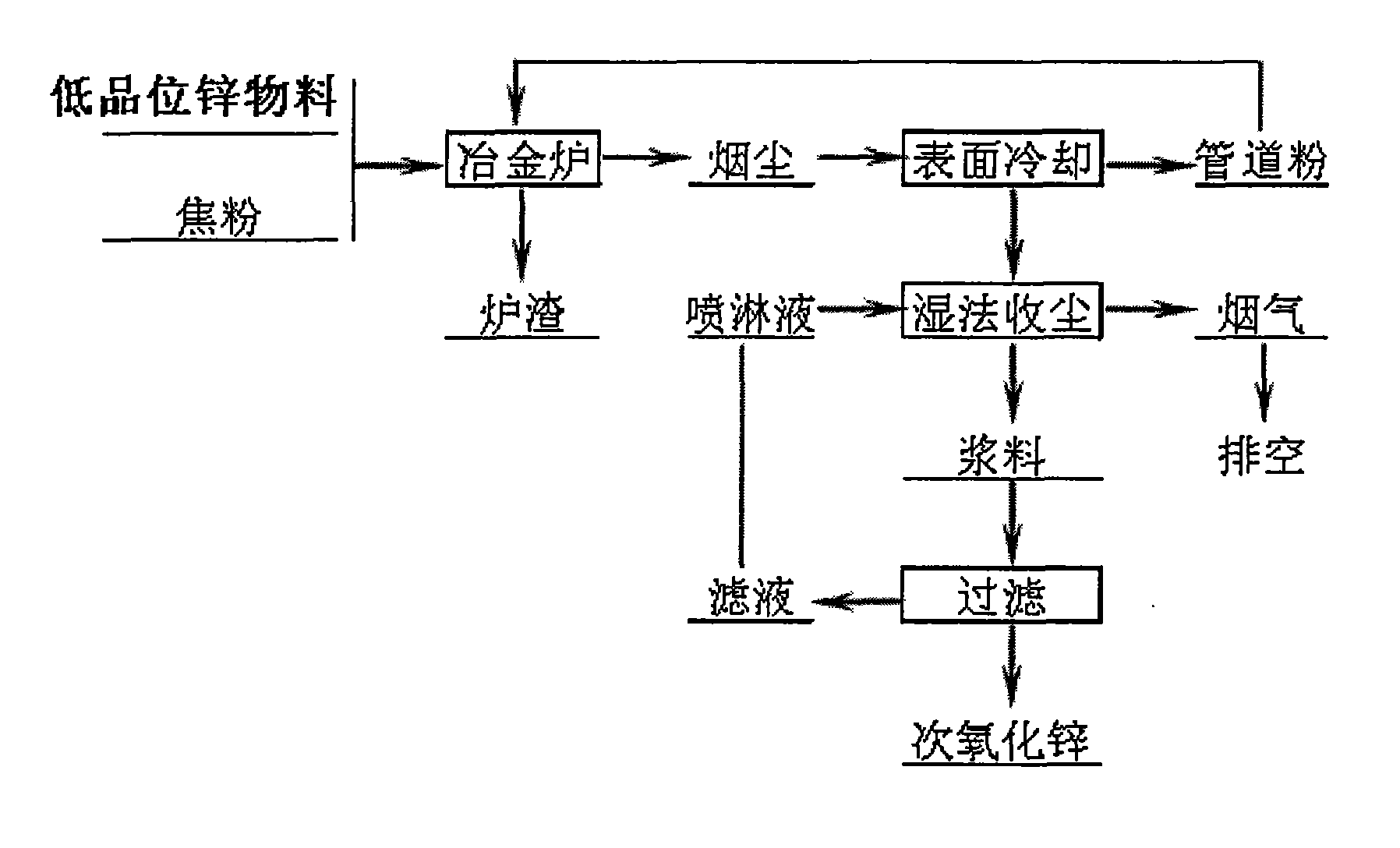

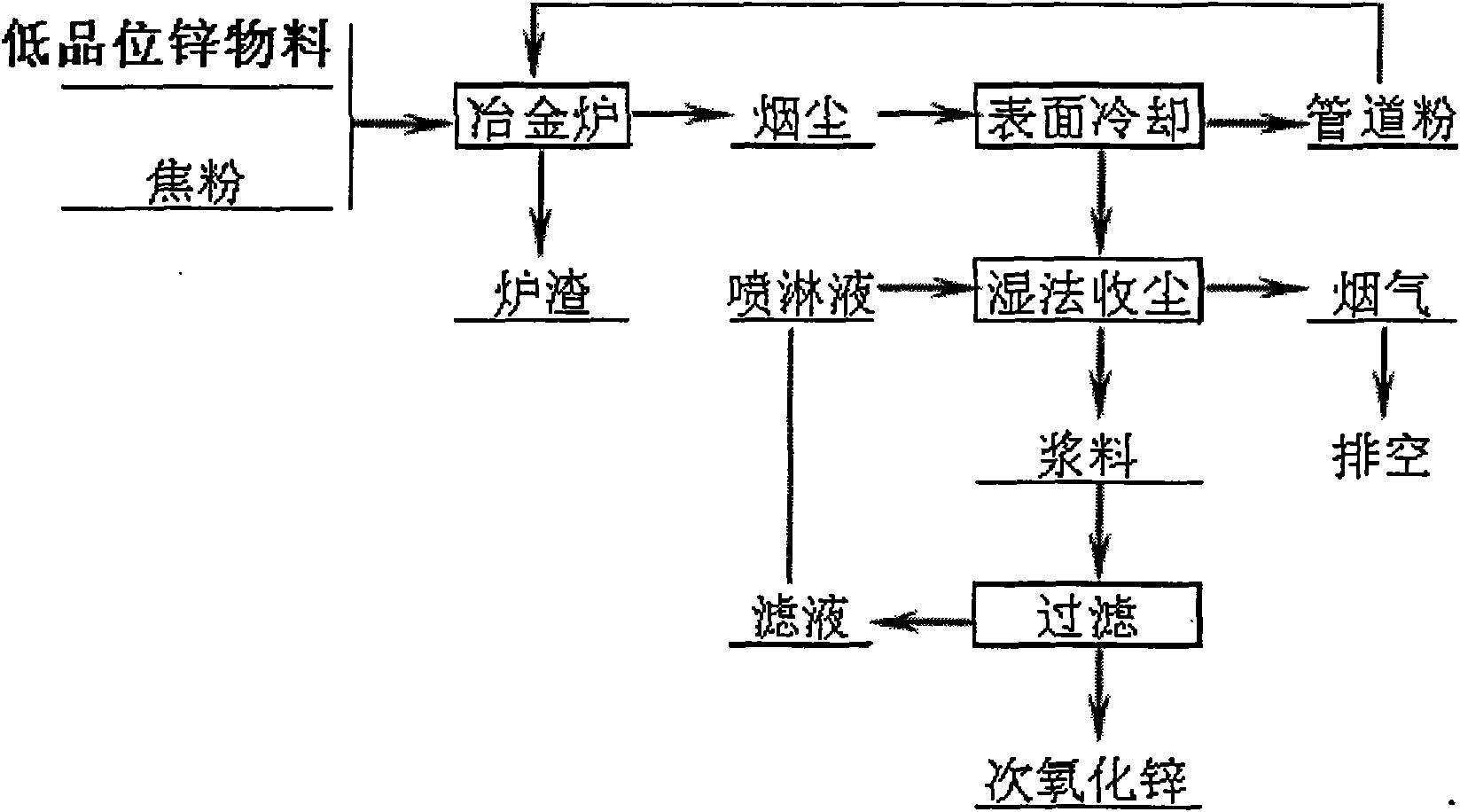

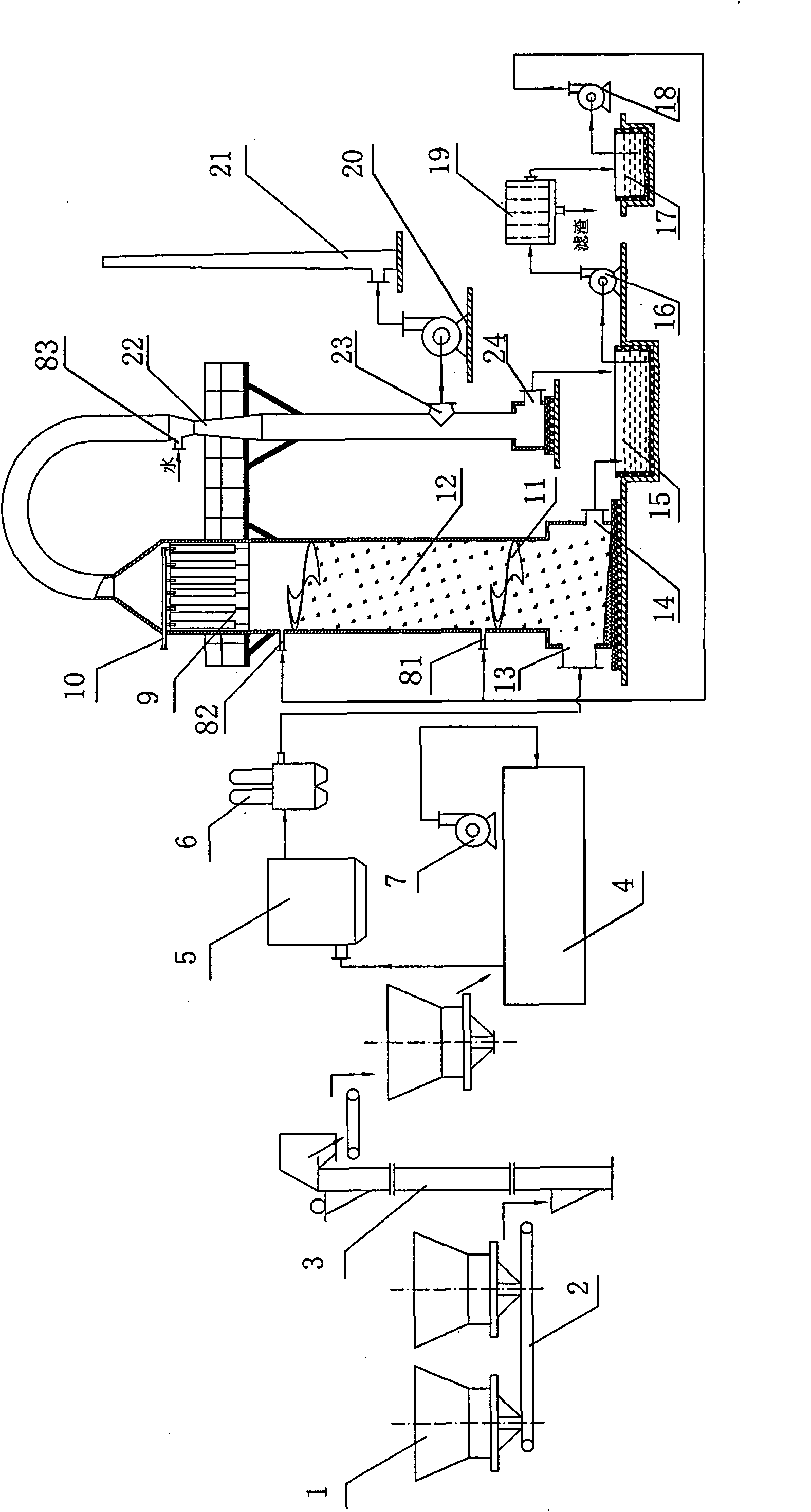

Cleaning and dust collecting method of volatilized zinc oxide and device thereof

InactiveCN101608266BAvoid the situation that the temperature is too high to burn the bagReduce cooling areaCombination devicesProcess efficiency improvementElectrolysisZinc Oxide Paste

The invention relates to a cleaning and dust collecting method of volatilized zinc oxide and a device thereof. Low grade zinc material is reduced and volatilized in a metallurgical furnace with reducing atmosphere; volatilized flue gas enters a spraying-cloth bag tower via an oxidizing chamber and a surface cooler; the zinc oxide in the flue gas is collected; fluorine and chlorine enter spraying solution; sulfur dioxide forms ZnSO3 to enter secondary zinc oxide paste; after the secondary zinc oxide paste is separated through filter pressing, the filter liquor returns to be circularly used; and filter residue is secondary zinc oxide product. The invention has the advantages that fluorine, chlorine and sulfur dioxide in the flue gas can be removed during the dust collection process, so as to enable the secondary zinc oxide to be directly used as the raw material for producing electrolytic zinc, the technological process can be reduced, the investment can be saved, and the invention is energy-saving and environment protective.

Owner:广西冶金研究院有限公司

A CNC double-station polishing machine

ActiveCN111941249BClean and orderly production environmentSuitable working environmentPolishing machinesGrinding machinesCircular discPolishing

The invention disclosed a CNC dual -station polishing machine, which involves the field of polishing equipment. There are two position adjustment mechanisms on the support frame in the chassis.The lower end of the polishing machine is connected to the protective device. The upper end of the protective device is equipped with a wax device. The supporting stand is provided with a workbench. There are turntables and disc drive mechanisms on the workbench. There are three workpieces on the turntable.There is a governance installation platform and workpiece rotating mechanism. There are sword repair devices on both sides of the turntable. The sword repair device is set away from the side of the turntable with a water curtain fixed rack.The institution is connected to a water circulation device, the case has an automatic lifting door and a side door, and the automatic lift curtain is provided between the side door and the water curtain fixed rack.The dust generated by polishing is captured by the water curtain mechanism and is used through the water circulation device to filter the cycle. The production environment is clean and orderly, creating a suitable working environment.

Owner:东莞市尚弘博实业有限公司

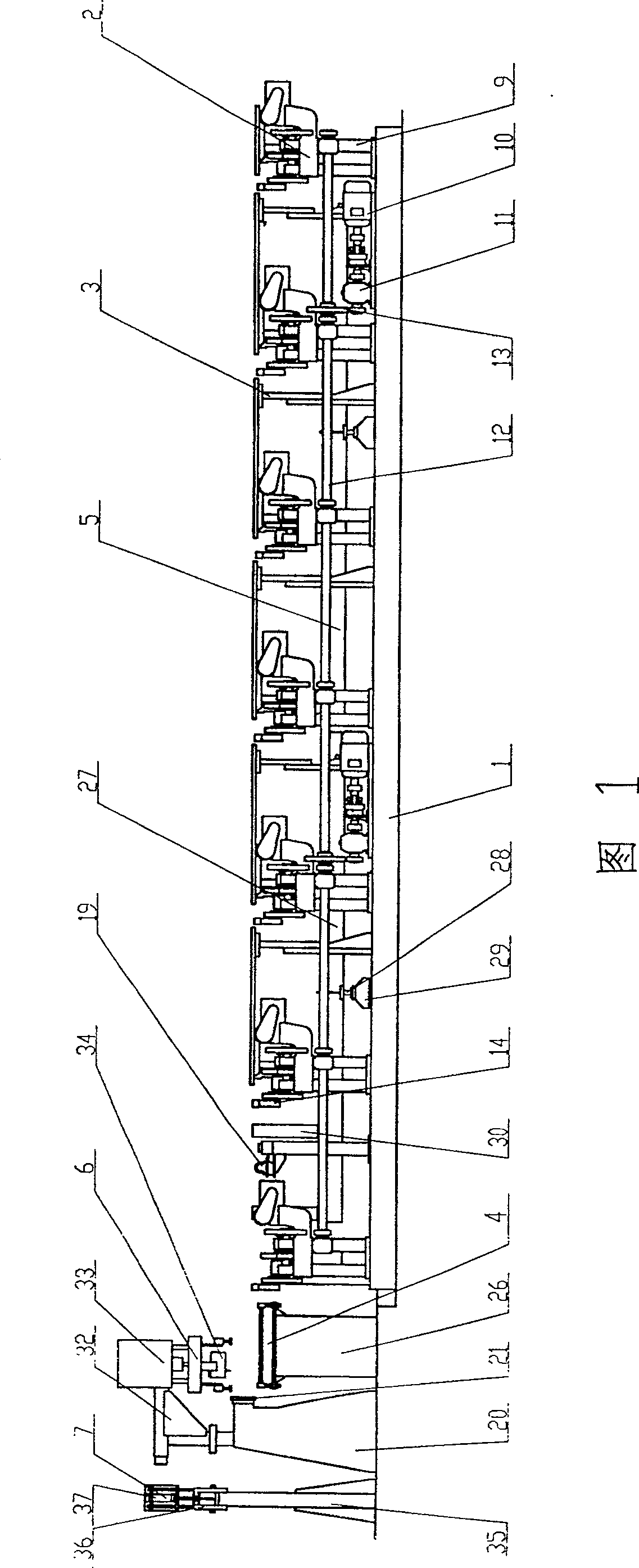

Steel pipe measuring device

InactiveCN100487393CIncrease productivityGuarantee product qualitySpecial purpose weighing apparatusElectric machineryNational standard

The steel tube measuring equipment relates to rack, five work stations walking beam institution, measuring length institution, painting institution, weighing institution, printer institution and spraying sign institution. According to the portrait axes to rack, set one five work stations walking beam institution driving by one and more motors on rack. According to the five work stations walking beam, set measuring length institution, painting institution, weighing institution, printer institution and spraying sign institution, from one end to the other end of rack in turn. Then complete measuring length, painting, weighing, printer and spraying sign to steel tube according to the national standard. It adopts not only mechanization flow operation, enhances production efficiency, assures product quality, and also greatly lightens labor intensity, realizes civilization production with safe and easy operation.

Owner:大连三高科技发展有限公司

A drilling machine for replacing air-permeable bricks in the hot state of converter bottom blowing

ActiveCN105441622BImprove the safety of useImprove operating conditionsManufacturing convertersThermal stateBrick

Owner:鞍山市和丰耐火材料有限公司

Punch sleeve cleaning machine

ActiveCN104550138BImprove working environmentReduce labor intensityHollow article cleaningDrive motorEngineering

The utility model discloses a punched seam sleeve cleaning machine, comprising a frame; a plurality of support rollers linearly arranged on the frame and used for bearing a punched seam sleeve; a rotation mechanism arranged on the frame and used for driving the punched seam sleeve to rotate; a rotation driving motor fixed on the frame and used for driving the rotation mechanism to rotate; a traveling mechanism arranged on the frame and moving on the frame along the axis direction of the punched seam sleeve; and a wheel brush cleaning mechanism arranged on the traveling mechanism and moving along with the traveling mechanism; the wheel brush cleaning mechanism comprises a cleaning wheel brush and a cleaning motor for driving the cleaning wheel brush to rotate; the cleaning wheel brush is rotated under the driving of the cleaning motor and contacts with the punched seam sleeve to be cleaned. The punched seam sleeve cleaning machine has the characteristics of high efficiency and good cleaning quality.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

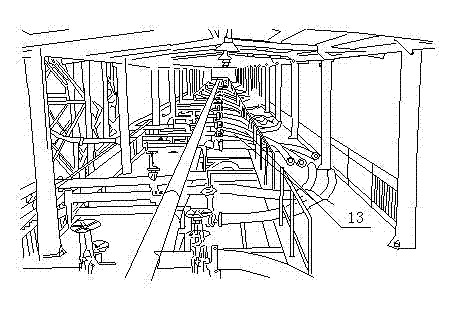

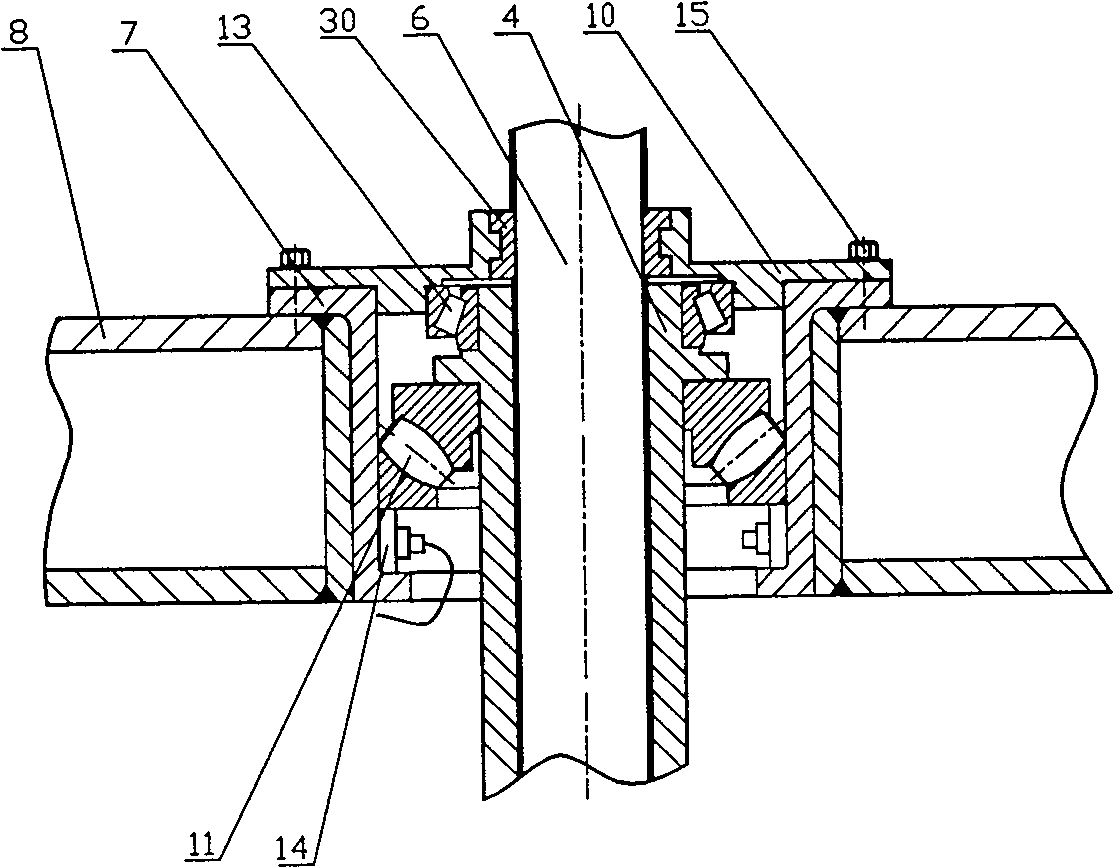

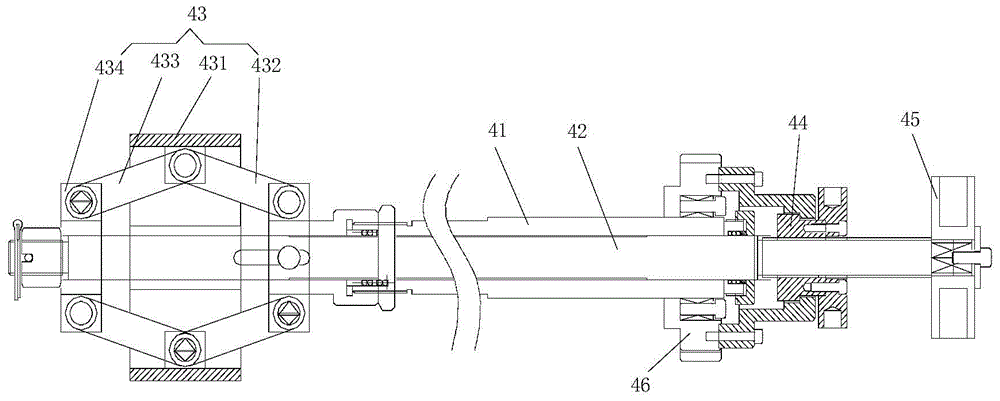

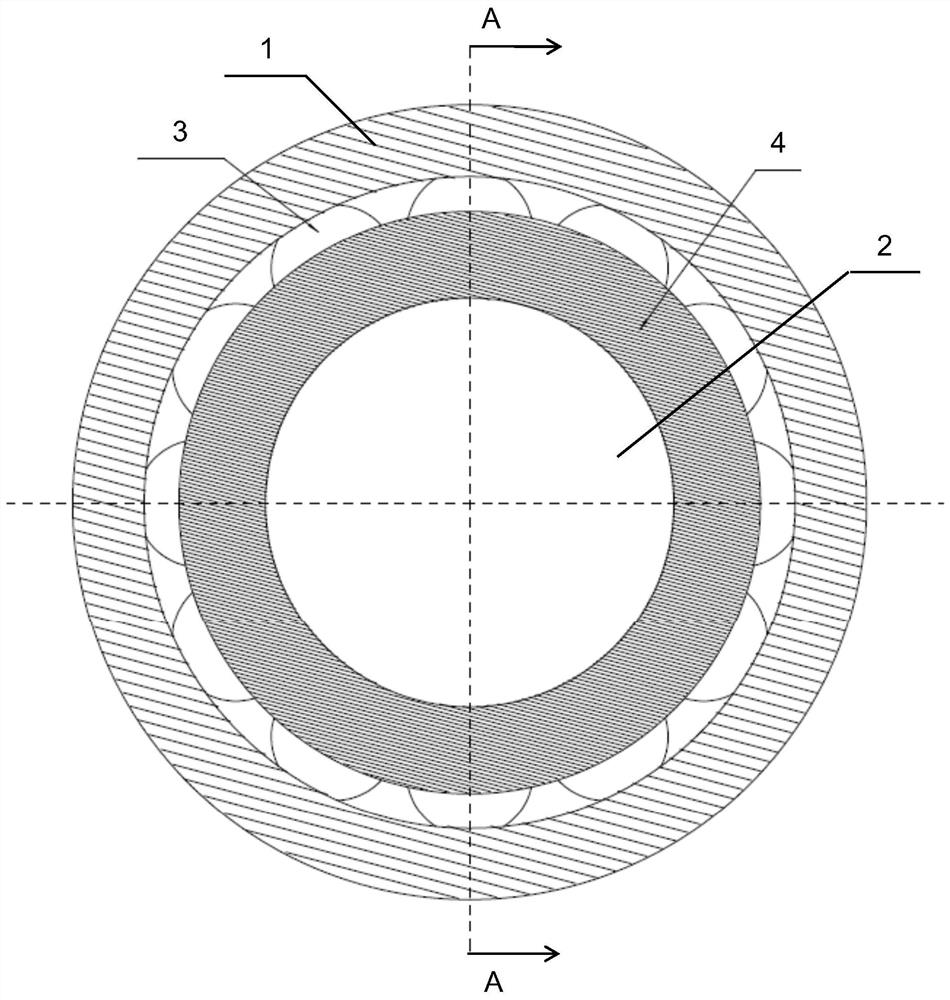

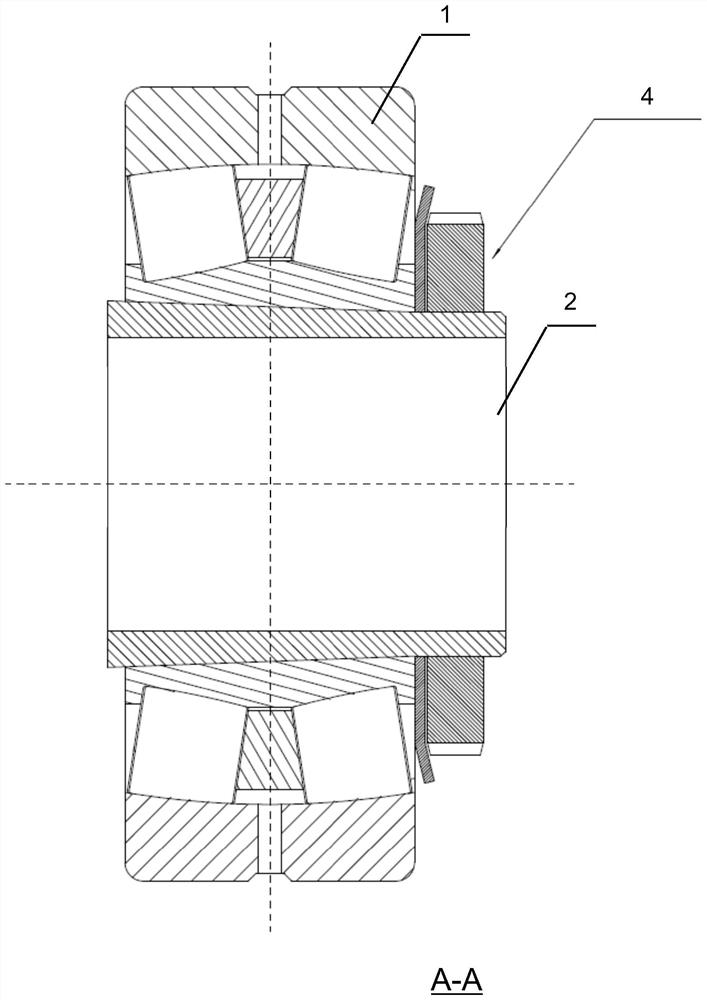

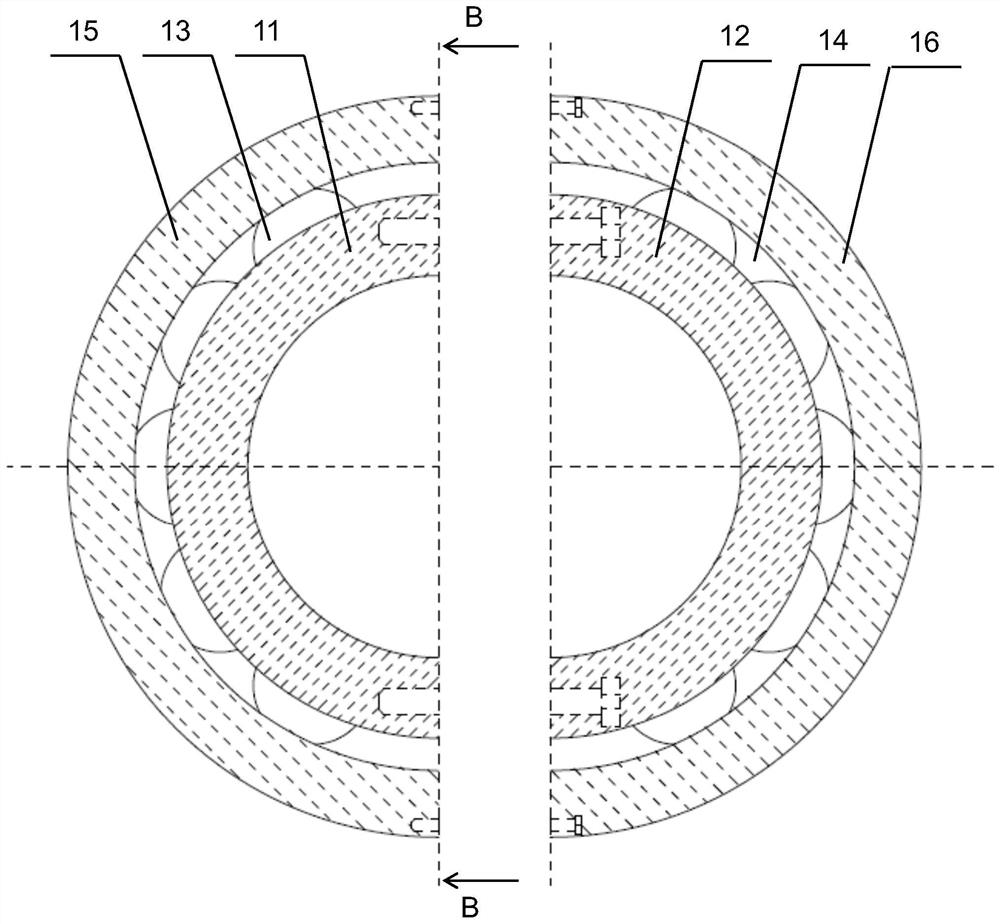

A bearing suitable for quick replacement on transmission equipment and its installation method

ActiveCN111197622BTroubleshootingGuaranteed uptimeBearing repair/replacementShaft repair/replacementStructural engineeringMechanical engineering

The invention discloses a bearing suitable for quick replacement on a transmission device and an installation method thereof. The bearing is arranged on a roll neck of a roller. The bearing comprises: an inner ring, a cage roller assembly and an outer ring which are sequentially fitted from the inside to the outside. It also includes: a fastening ring, a positioning spring ring, and the inner ring, the cage roller assembly, the outer ring and the fastening ring are all of a half-split structure. The invention can quickly deal with the difficult problem of bearing failure replacement under emergency conditions, thereby reducing downtime of equipment failure and ensuring stable operation of the equipment system.

Owner:BAOSHAN IRON & STEEL CO LTD

Loose-packed gel material parallel ash-unloading system

Owner:中国水利水电第四工程局有限公司第六分局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com