Steel pipe measuring device

A technology for measuring devices and steel pipes, which is applied in the direction of measuring devices, weighing, instruments, etc., can solve the problems of cumbersome and complicated labor intensity, unsafe operation, high labor intensity, etc., and achieve the goals of reducing labor intensity, operating safety, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

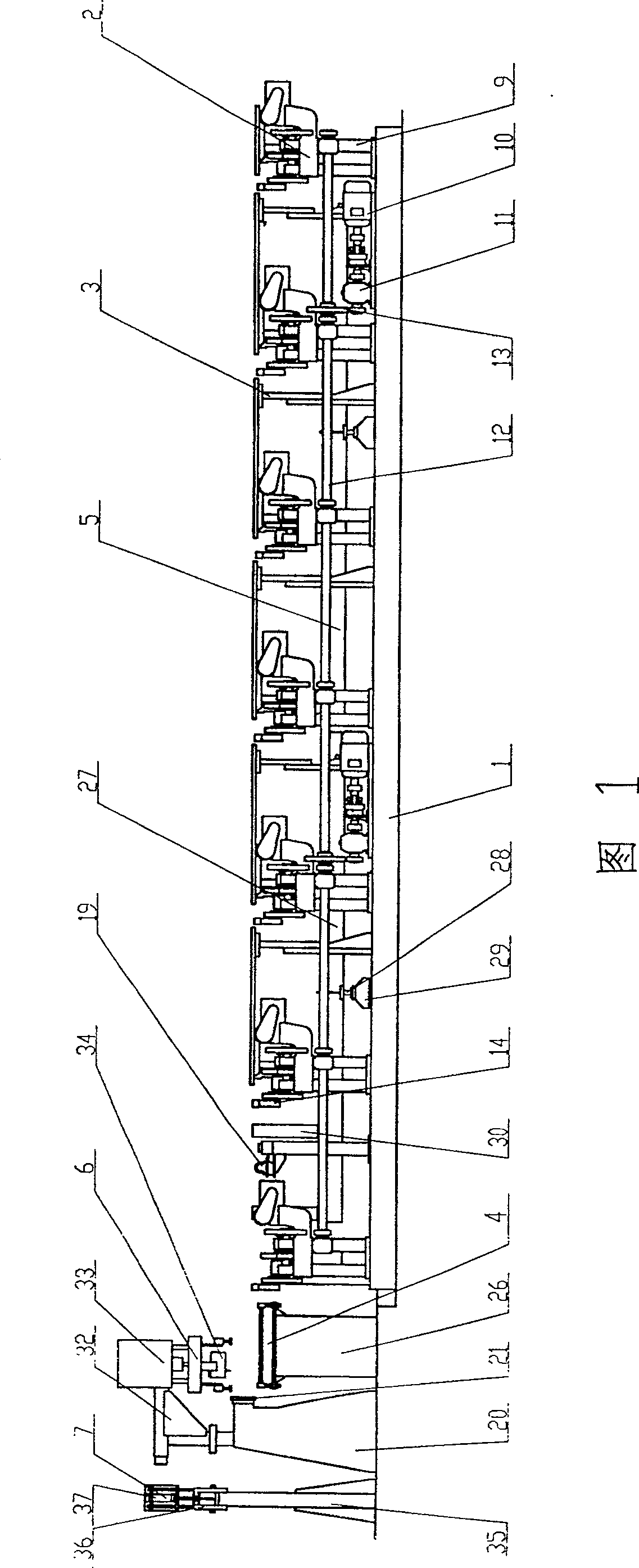

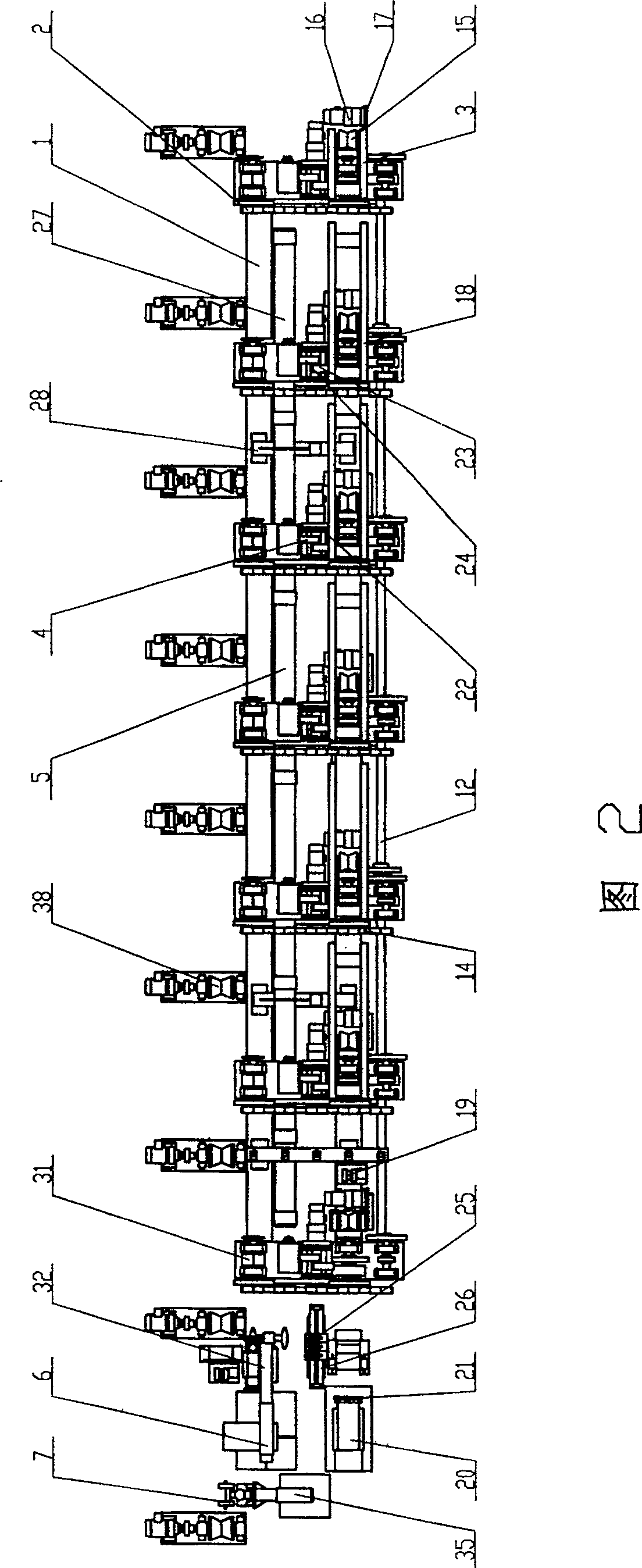

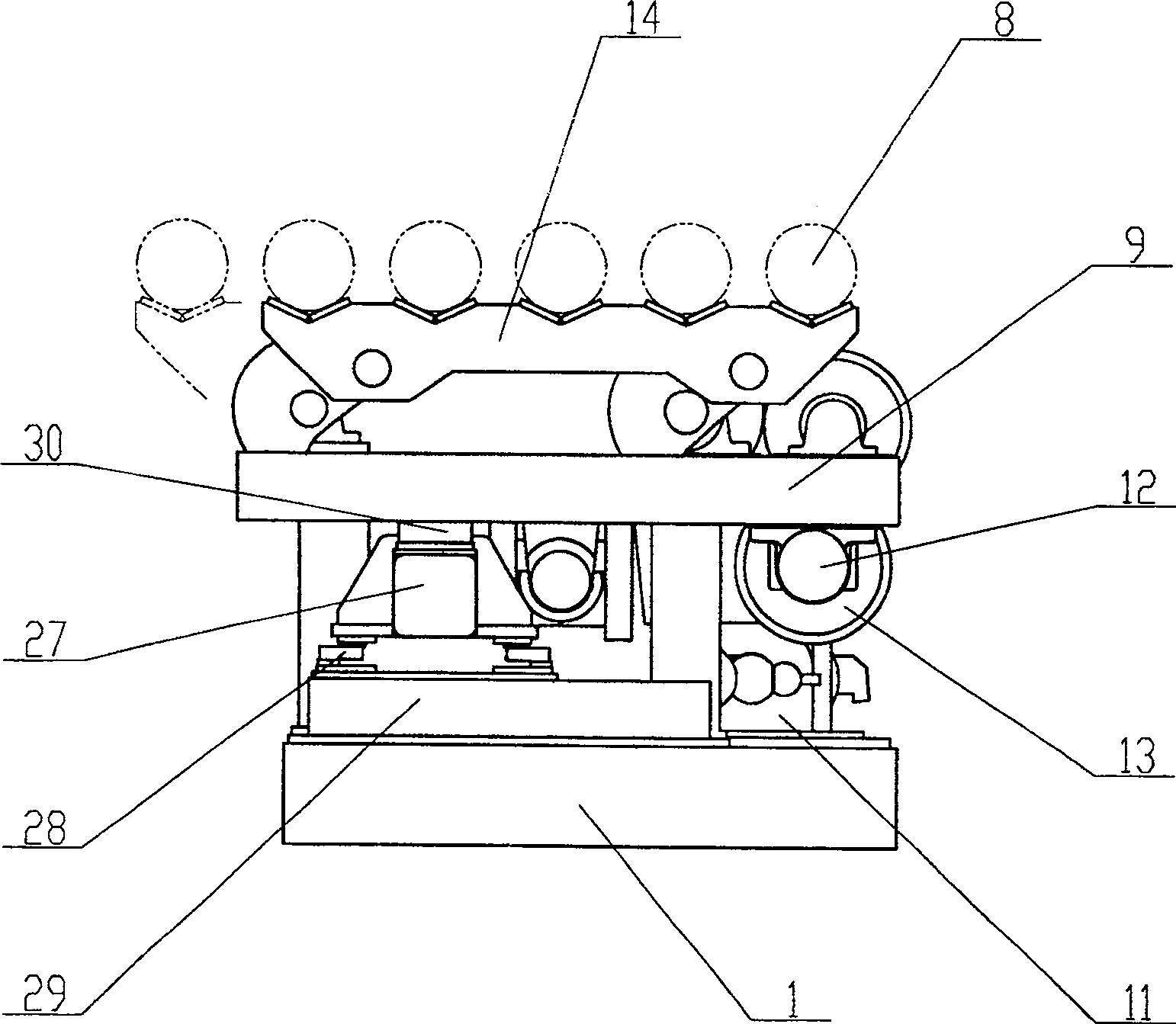

[0017] Shown in Fig. 1,2,3 is the specific embodiment of the present invention, and it is the steel pipe measuring device of the walking beam mechanism 2 of five stations driven by two motors 10, is characterized in that: its structure mainly comprises frame 1, The five-station walking beam mechanism 2, the length measuring mechanism 3, the coloring mechanism 4, the weighing mechanism 5, the printing mechanism 6, and the spraying label mechanism 7 are composed of the longitudinal axis of the frame 1, and the motor 10 is installed on the frame 1 to drive it. The five-station walking beam mechanism 2 corresponding to the five-station walking beam 14 in the five-station walking beam mechanism 2, along the lateral side of the frame 1 to the other side, on the frame 1 according to The length measuring mechanism 3, the coloring mechanism 4, the weighing mechanism 5, the printing mechanism 6 and the label spraying mechanism 7 are assembled in sequence; Sprocket transmission 13, power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com