A bearing suitable for quick replacement on transmission equipment and its installation method

An installation method and transmission equipment technology, applied in the direction of bearings, ball bearings, shafts and bearings, etc., can solve problems such as cumbersome procedures, difficult construction, and long time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

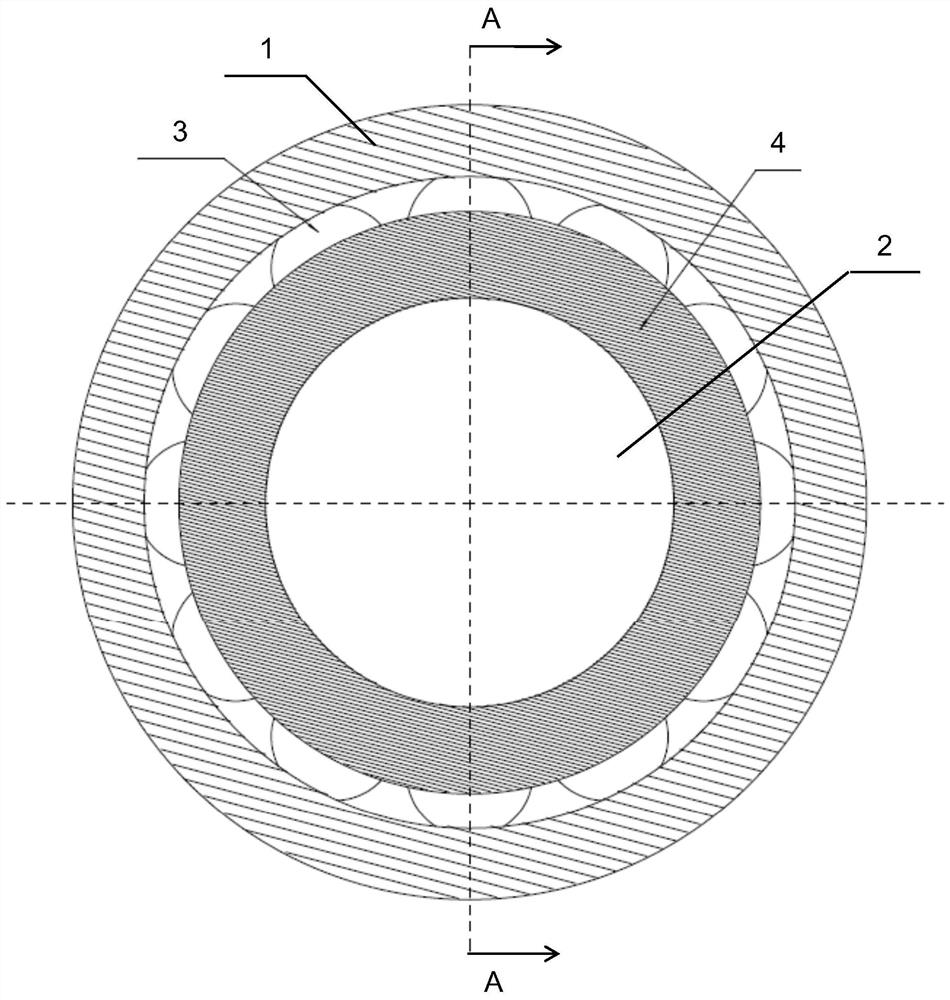

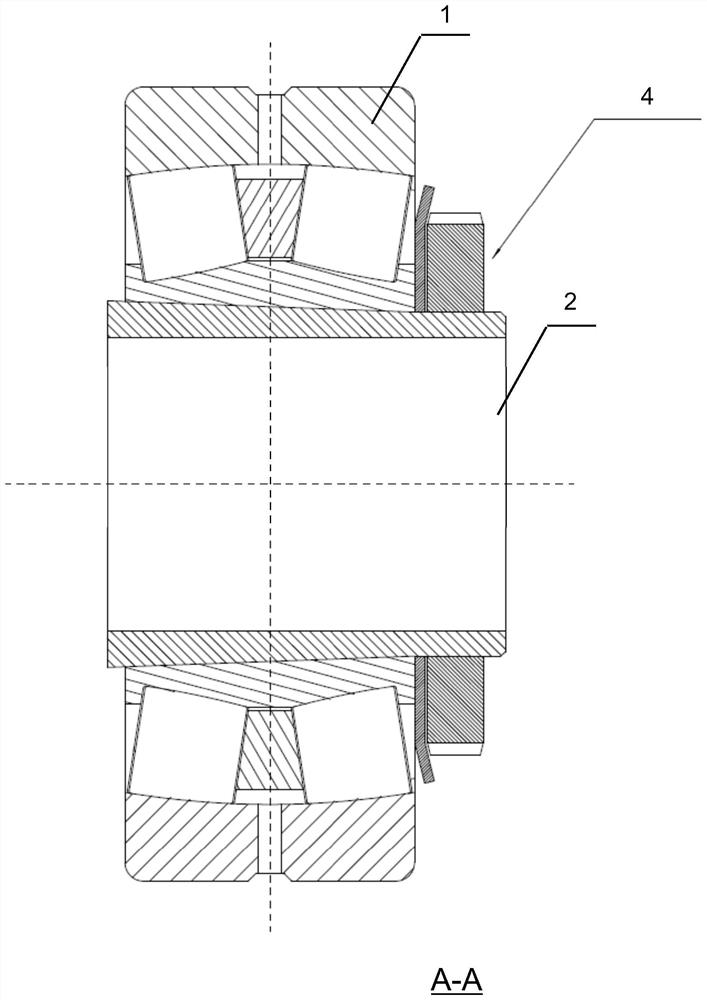

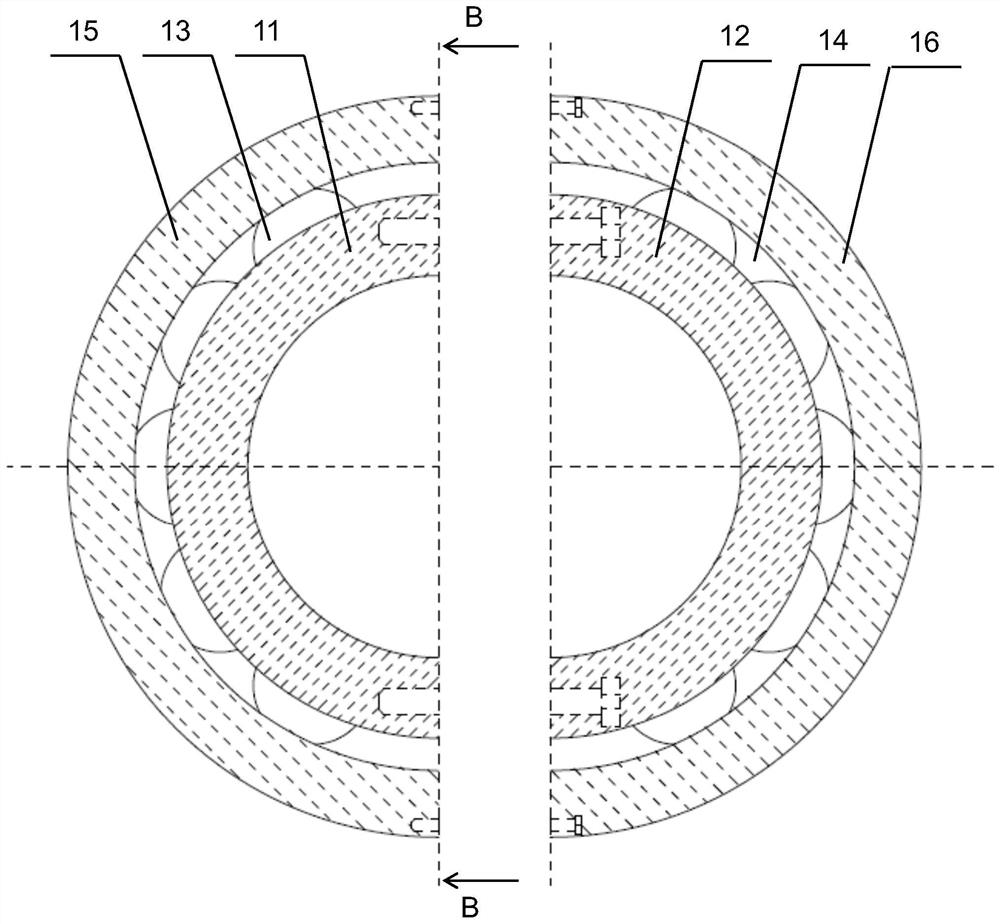

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Please combine Figure 3 to Figure 4 As shown, the present invention provides a bearing suitable for quick replacement on transmission equipment, which is arranged on the roll neck of the roller. The bearing includes: an inner ring, a cage roller assembly and an outer ring that are sequentially fitted from the inside to the outside. The foregoing is part of the prior art, and will not be repeated here. Different from the prior art, it also includes: the fastening ring, the positioning spring ring 10, and the inner ring, the cage roller assembly, the outer ring and the fastening ring are all of a half-split structure. With the split structure, you only need to drag the half handle on the side of the driving drum (no need to pull out the half handle) on site, then replace the bearing of the half split structure, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com