Wire hanging rack for vehicle denso production open wire machine

A technology of hanging wire rack and wire opening machine, which is applied in the direction of cable installation, cable installation device, circuit, etc. It can solve problems such as unreasonable wire rack design, affecting the overall environment of the production process, and no hanging wires on wires, etc., to achieve a working platform Humanized, convenient classification and shelves, more effective working platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

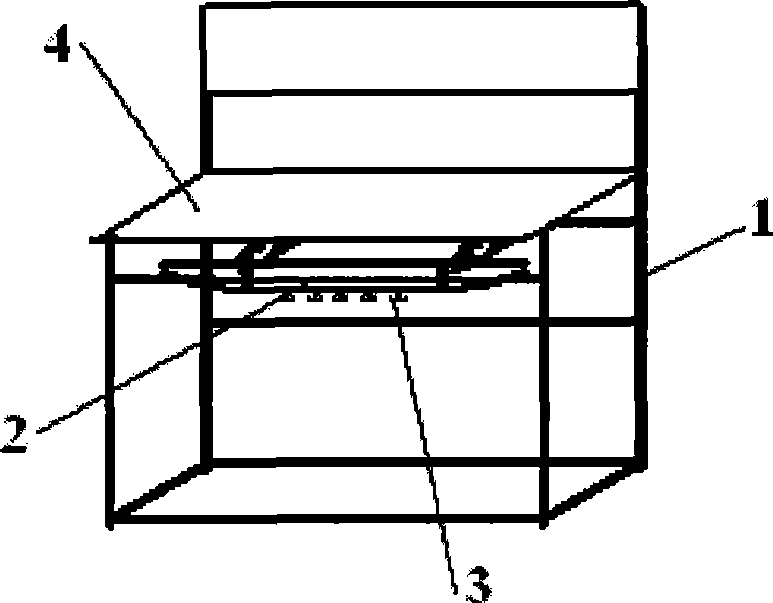

[0026] The number of the wire hanging rods 2 in the present invention is two or more, and they are parallel to each other. With this structure, it is convenient for the operator to classify and put the semi-finished product line on the shelf, and it is not easy to be confused. Each semi-finished product is hung on a wire rod, which is easy to distinguish.

Embodiment 2

[0028] The hanging rod 2 of the present invention is provided with a hook 3 fastened thereto. The semi-finished products produced by the full-automatic unwinding machine are tied into a bunch by a certain amount and hung on the hook 3, which is more convenient than directly hanging on the wire hanging rod 2, and can not all be mixed together.

Embodiment 3

[0030] There are two or more hooks 3 in each hanging rod 2 according to the present invention. Multiple hooks 3 facilitate the storage of more wire harness products. The distances between the hooks 3 are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com