Large-scale die-forging hydraulic press hybrid power hydraulic transmission system and method

A hybrid and hydraulic transmission technology, applied in the driving device, press, and manufacturing tool of forging presses, can solve the problems of increased production and operation costs, increased project investment, low startup rate and operating efficiency, and reduced procurement costs. , The effect of improving operating efficiency and boosting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention, but not to limit the scope of the present invention.

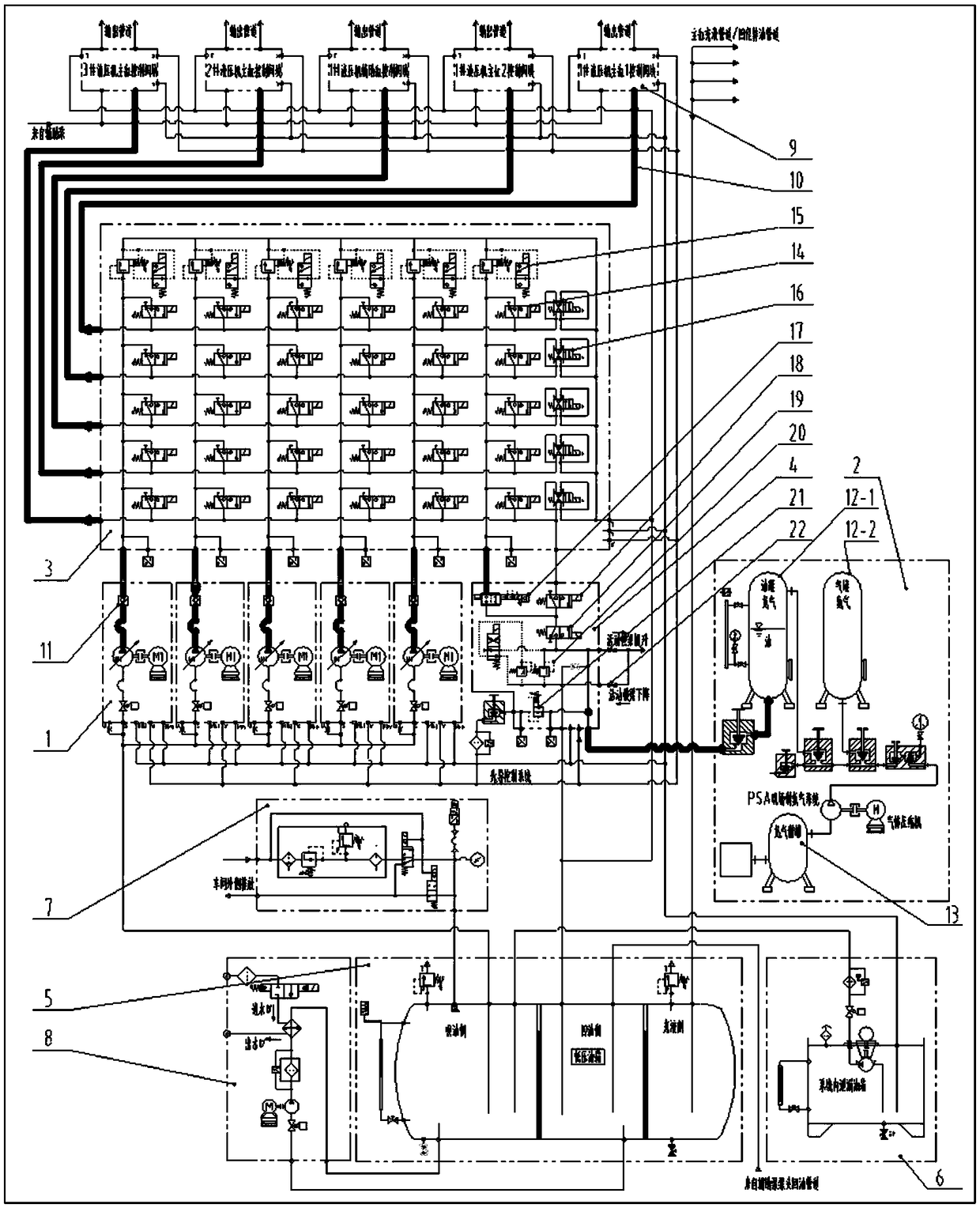

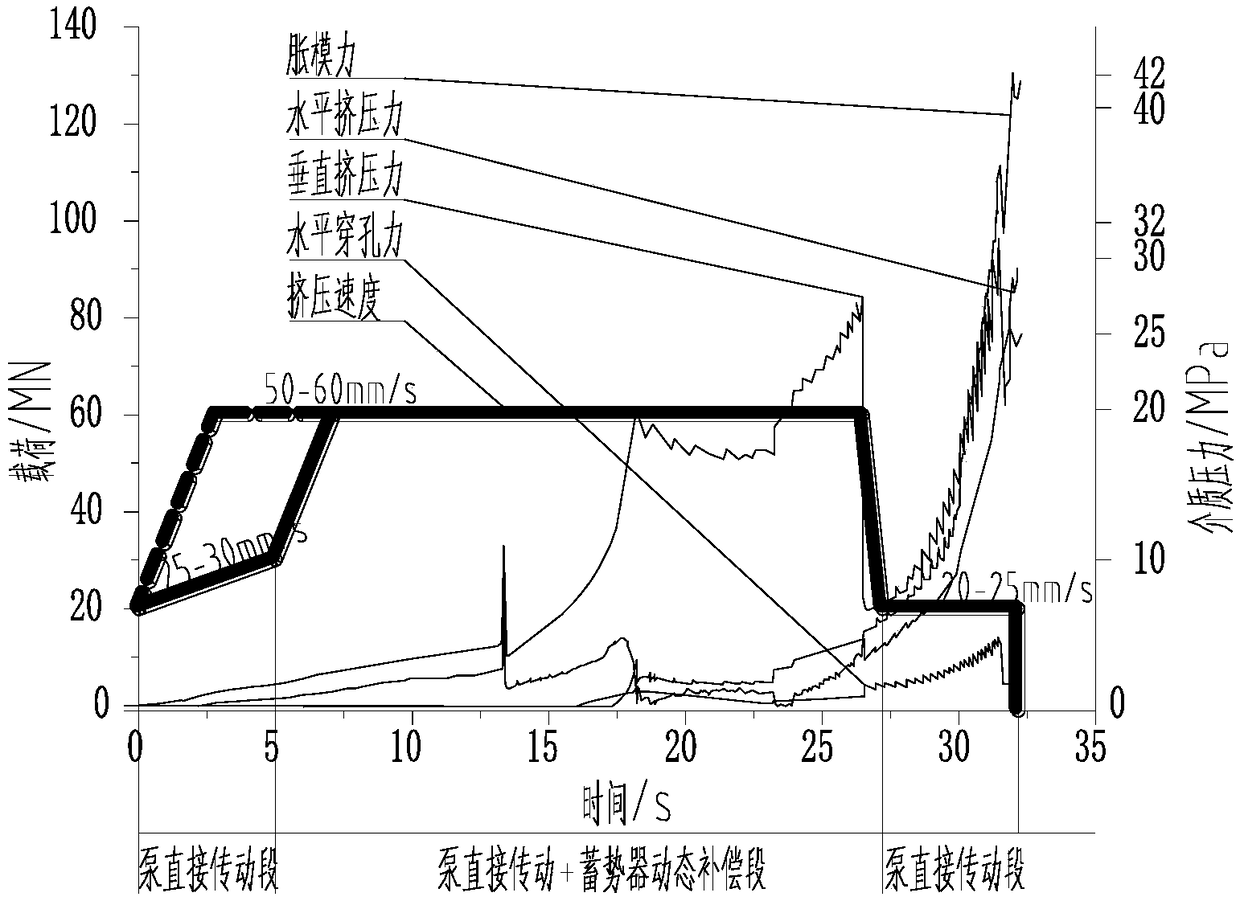

[0036] Hybrid power hydraulic transmission system for large-scale die forging hydraulic press, the main devices include: several ultra-high pressure plunger variable pumps, several Taichung high-pressure accumulators, low-pressure oil tanks and non-pressure oil tanks and their circulation systems, matrix multi-channel output integrated control valve block , PSA on-site nitrogen system, etc. Each device is organically connected through a pipeline with a suitable flow rate, thus forming a multi-directional die extrusion, die forging, isothermal die forging, equal reduction forming, equal forging ratio forming, precision forming, superplastic forming and other metal-plastic flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com