A drilling machine for replacing air-permeable bricks in the hot state of converter bottom blowing

A converter bottom-blowing and air-permeable brick technology, which is applied in the manufacture of converters and other directions, can solve the problems of easy deformation and fracture of couplings, inability to adjust the drilling speed of frequency, and low drilling accuracy, so as to improve the safety performance and ensure the safety of use. The effect of normal production rhythm of steelmaking and improvement of drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

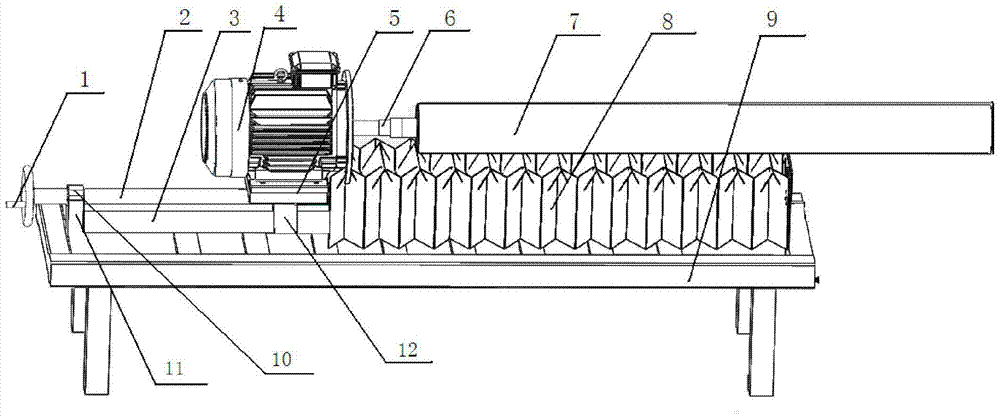

[0026] Such as figure 1 As shown, a drilling machine for replacing air-permeable bricks in a converter bottom blowing hot state includes a motor 4, a hollow drill bit 7, and a coupling 6. The output shaft of the motor 4 is connected to the hollow drill bit 7 through the coupling 6; it also includes a ball Lead screw 2, slideway 3, dustproof cover 8, described motor support 5 and slideway 3 sliding connection, one end of slideway 3 is fixed with nut holder 11, and the nut 10 of ball screw 2 is fixed on slideway On the nut holder 11 at one end, one end of the ball screw screw is fixed with a feed rocker 1, the other end is fixed axially with the motor base 5 and rotates relative to the radial direction, and a dust cover 8 is arranged at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com