Automobile electric fitting production line

A production line and assembly line technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of affecting the quality and performance of finished products, changing product specifications and models, parts, and related auxiliary materials, so as to improve the production environment and ensure product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

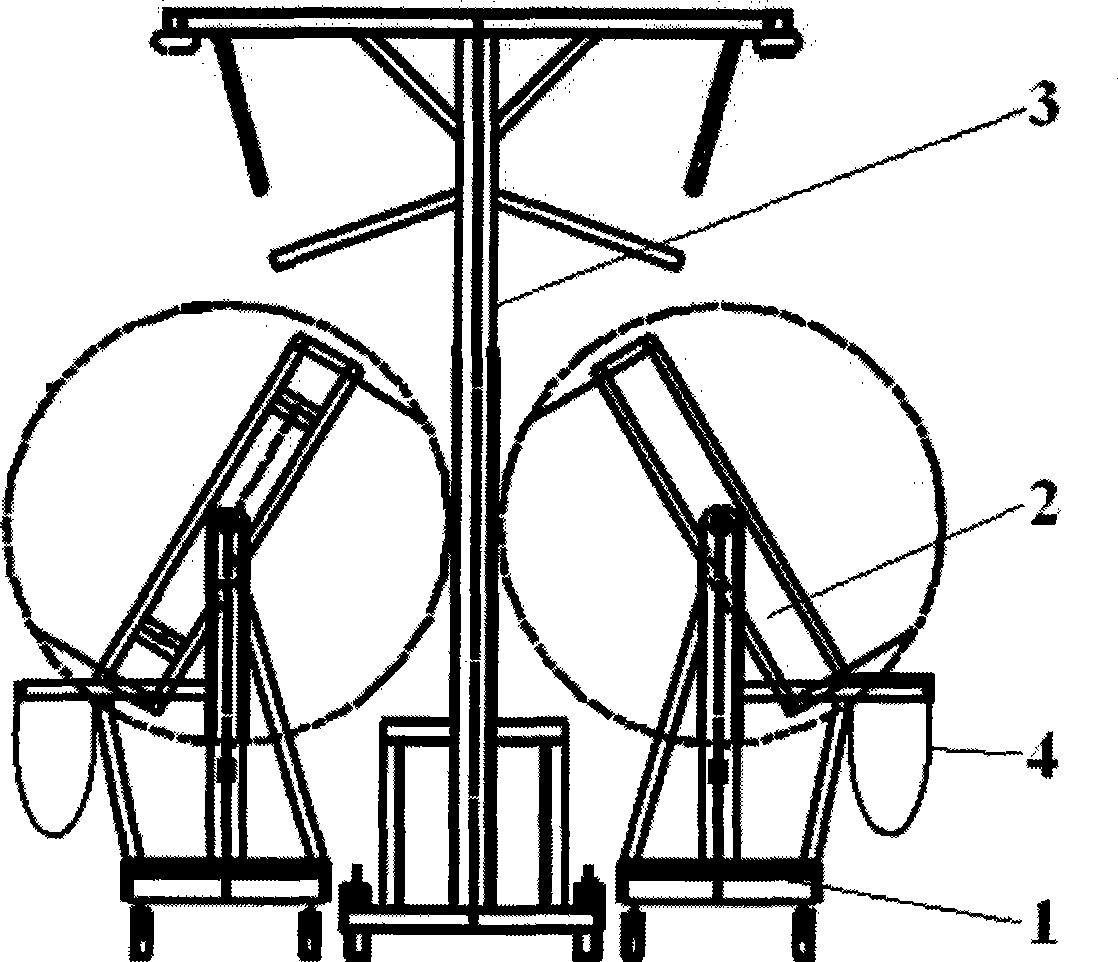

[0023] The size of the cloth pocket 4 according to the present invention along the length direction of the electrical equipment operating panel 2 is equal to that of the electrical equipment operating panel 2 . In this way, the wires and accessories will not fall to the ground in the length direction of the entire electric board.

Embodiment 2

[0025] Cloth pocket 4 of the present invention is the recess of groove shape, makes it become the groove of U shape, and the longitudinal direction of its groove shape is parallel with the longitudinal direction of electrical equipment operation panel 2. Due to the use of U-shaped grooves, the wires hanging down will be collected and concentrated by the cloth pocket to limit their scattering, and the civilization level of the production site will be improved.

Embodiment 3

[0027] The cloth of cloth pocket 4 of the present invention is nylon, or is canvas, or is acrylic. The cloth of different cloth pocket 4 of above-mentioned each embodiment is selected for use, and its purpose is to guarantee the intensity of cloth pocket 4, prolongs its service life. It can be selected according to the conditions of existing production and supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com