Multifunctional production line of light gypsum panel

A multi-functional, production line technology, applied in the direction of ceramic molding machines, chemical instruments and methods, clay preparation equipment, etc., can solve the problems of single production products, large investment, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

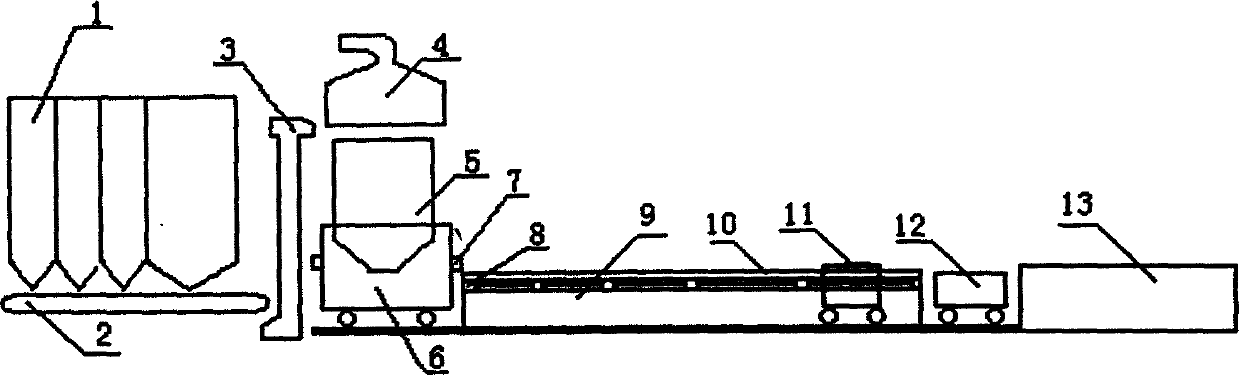

[0045] 1. Production product variety: three-dimensional reinforced gypsum board, specification 900×600×25(mm)

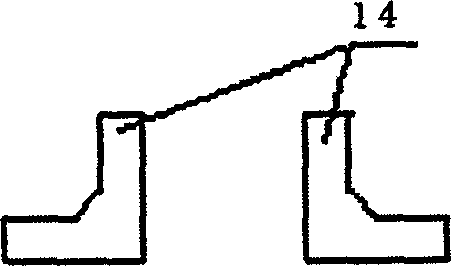

[0046] 2. Interchangeable side mold: 25mm high straight mouth interchangeable side mold

[0047] 3. Production process

[0048] According to the product mix ratio, put the fiber and water into the mixer with a rotation speed of 200 rpm, and stir for 2 minutes. Then add lignocellulose, medium-alkali glass fiber, gypsum powder, expanded perlite, redispersible rubber powder, etc. and stir for 1 minute. Then, start the watering vehicle, and when the watering vehicle advances at a constant speed on the track, pour the mixed slurry onto the forming platform that has fixed the straight mouth type interchangeable side mold (25mm high). While pouring, the slurry scraper 7 scrapes the slurry.

[0049] Stand still for 5-8 minutes. After the slurry hardens, draw the cutting line of the product length (900mm) according to the scale line on the interchangeable side mold. Loose...

example 2

[0054] 1. Production product variety: double fiber reinforced gypsum board, specification 900×600×30(mm)

[0055]2. Interchangeable side mold: 30mm high straight mouth interchangeable side mold

[0056] 3. Production process

[0057] According to the product mix ratio, raw materials such as gypsum powder and expanded perlite are lifted into the slurry mixer through the bucket elevator, and the measured water is added. After stirring for two minutes, stop stirring. Then, start the watering vehicle, and when the watering vehicle advances at a constant speed on the track, the mixed slurry is poured onto the forming platform on which the straight mouth interchangeable side mold (30mm high) has been fixed. While pouring, lay the upper and lower layers of glass fiber mesh cloth, and the slurry scraper to level the slurry.

[0058] Stand still for 5-8 minutes. After the slurry hardens, draw the cutting line of the product length (900mm) according to the scale line on the interchang...

example 3

[0063] 1. Production product variety: block gypsum, specification 600×500×80(mm)

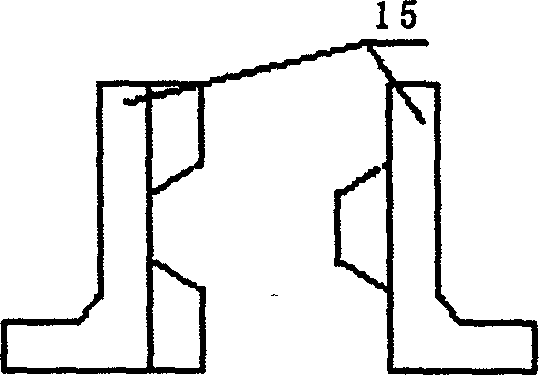

[0064] 2. Interchangeable side molds: interchangeable side molds with a height of 80mm

[0065] 3. Production process

[0066] The interchangeable mold (80mm high) of the female and female mouth shapes is fixed on the forming platform with the side mold clips, and the female and female mouth shape crosspieces 36 are fixed at the interval of 500mm in the interchangeable mold.

[0067] According to the product mix ratio, the raw materials such as gypsum powder and expanded perlite are lifted into the slurry mixer through the bucket elevator, and the measured water is added, and the stirring is stopped after 1 minute. Then, start the watering vehicle, and when the watering vehicle advances at a constant speed on the track, pour the mixed slurry onto the forming platform on which the side molds (80mm high) and the crosspieces of the female and female mouths have been fixed. While pouring, the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com