Automatic control production process for medicinal barium sulfate

A production process, the technology of barium sulfate, applied in the field of automatic control production process of medicinal barium sulfate, can solve the problems of inability to accurately control the particle size range of barium sulfate, low pass rate of barium sulfate, etc., to achieve civilized production and improve operation Environment and labor intensity, the effect of optimizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

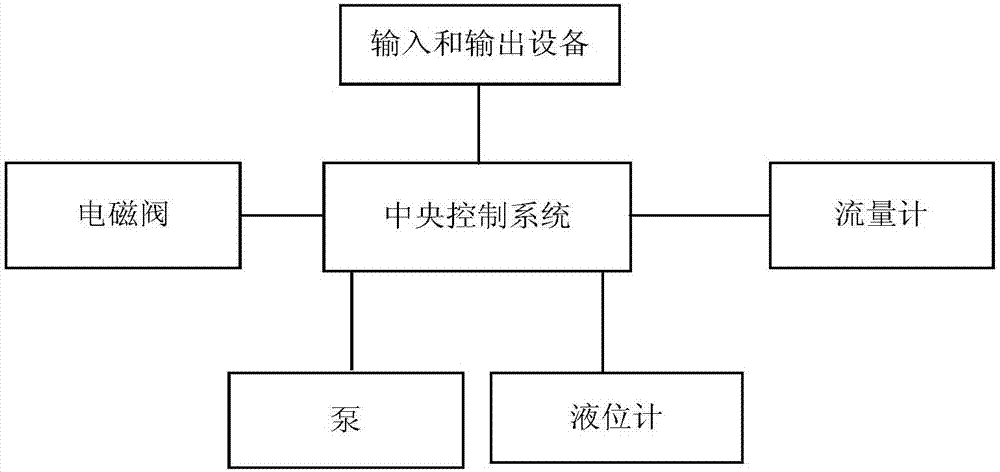

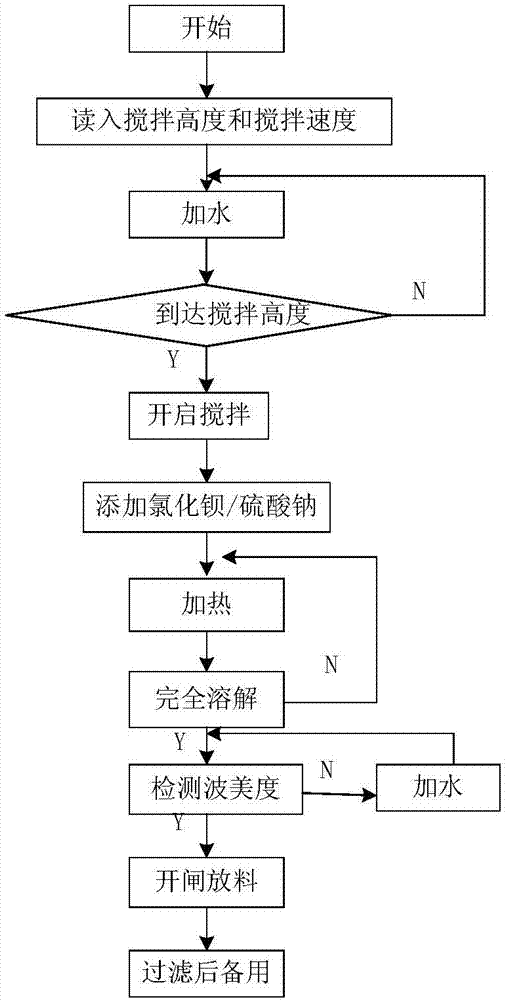

[0034] figure 2 A process flow chart for the preparation of barium chloride / sodium sulfate is provided.

[0035] The preparation process of barium chloride solution: the central control system issues instructions, the cold water pump starts, and drinking water is added to the barium chloride tank. The liquid level gauge detects the water level in the barium chloride tank. When the water level reaches the set height, the agitator starts , the central control system issues an instruction, the feed valve is opened, the barium chloride is pumped into the barium chloride tank, the flow meter detects the flow rate of sodium sulfate, when the set flow rate is reached, the feed is stopped, the steam valve is opened for heating, and the barium chloride is stirred until it reaches the set flow rate. Dissolution, the temperature sensor detects the temperature of the liquid in the barium tank, the temperature is controlled within the set range, the solution is taken to measure the Baume ...

Embodiment 1

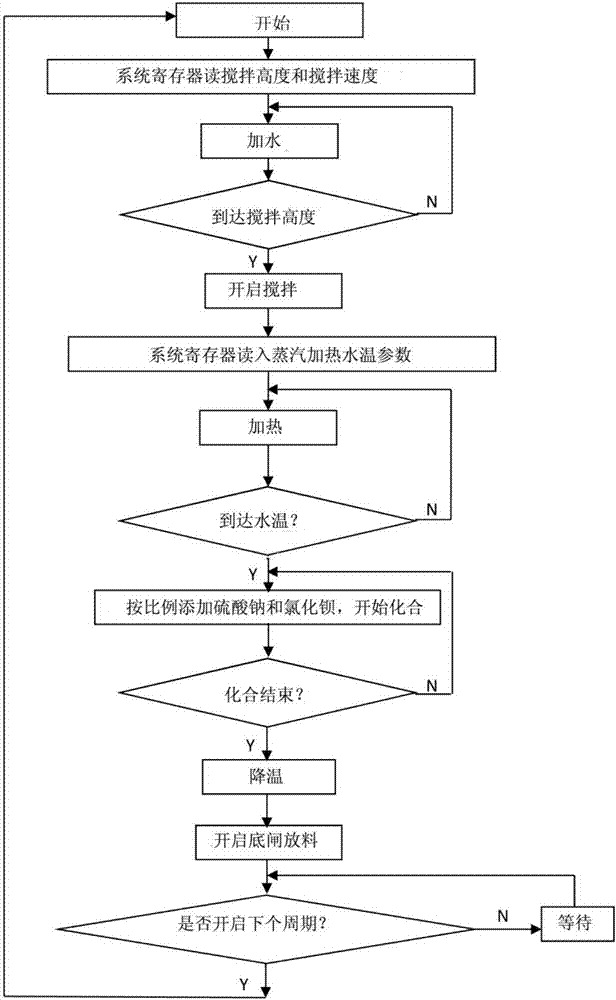

[0042] This embodiment provides a synthesis process of medicinal barium sulfate.

[0043] 1. Feed according to Table 1.

[0044] Table 1

[0045] Material name Specification Feed material / batch use Industrial Barium Chloride ≥98.0% 3250kg Raw material for barium sulfate synthesis Industrial Sodium Sulfate ≥98.0% 1900kg Raw material for barium sulfate synthesis

[0046] 2. Process flow:

[0047] (1) Preparation of barium chloride solution (abbreviated barium solution):

[0048] The central control system issues instructions, the cold water pump starts, and drinking water is added to the barium tank. The liquid level gauge detects the water level in the barium tank. When the water level reaches 2 / 3 of the barium tank, the agitator starts, and the central control system Instructions are issued, the feed valve is opened, the barium chloride is pumped into the barium chloride tank, and the flow meter detects the flow rate of sodium sulfate...

Embodiment 2

[0056] This embodiment provides a synthesis process of medicinal barium sulfate.

[0057] 1. Feeding is carried out as shown in Table 1 of Example 1.

[0058] 2. Process flow:

[0059] (1) Preparation of barium chloride solution (abbreviated barium solution):

[0060] The central control system issues instructions, the cold water pump starts, and drinking water is added to the barium tank. The liquid level gauge detects the water level in the barium tank. When the water level reaches 2 / 3 of the barium tank, the agitator starts, and the central control system Instructions are issued, the feed valve is opened, the barium chloride is pumped into the barium chloride tank, and the flow meter detects the flow rate of sodium sulfate. When the set flow rate is reached, the feed is stopped, the steam valve is opened for heating, and the barium chloride is stirred until the barium chloride is dissolved, and the sample is measured. The Baume degree of the solution, the central control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com