Full electrodynamic mould locking device of rubber injection machine

A technology of a clamping device and an injection machine, which is applied in the field of all-electric clamping devices for rubber injection machines, can solve the problems of a clamping device that is not suitable for a large stroke, affects reliability, and has high operating costs, and saves space and floor space. , The effect of improving the fixed force condition and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are not intended to limit the present invention.

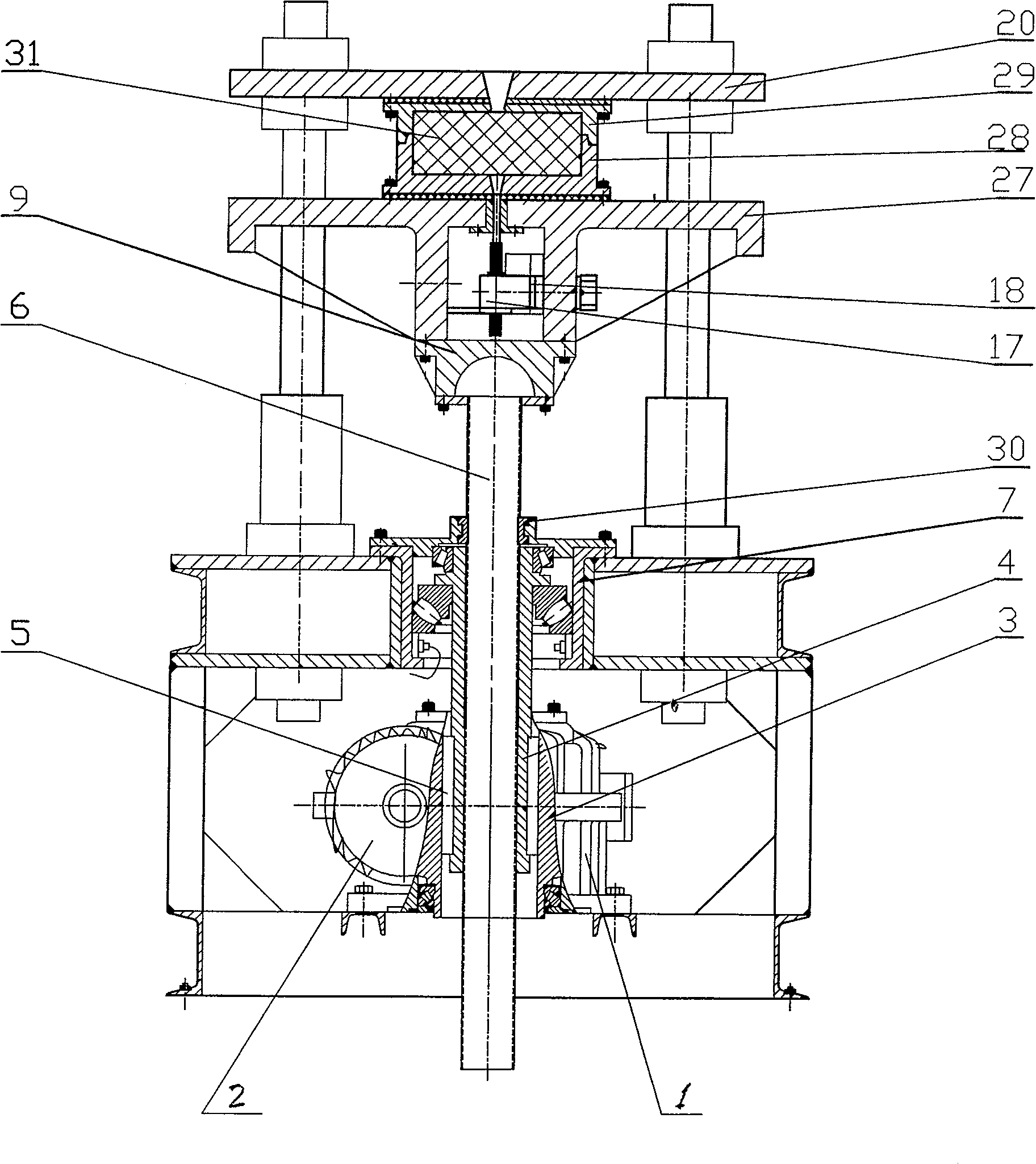

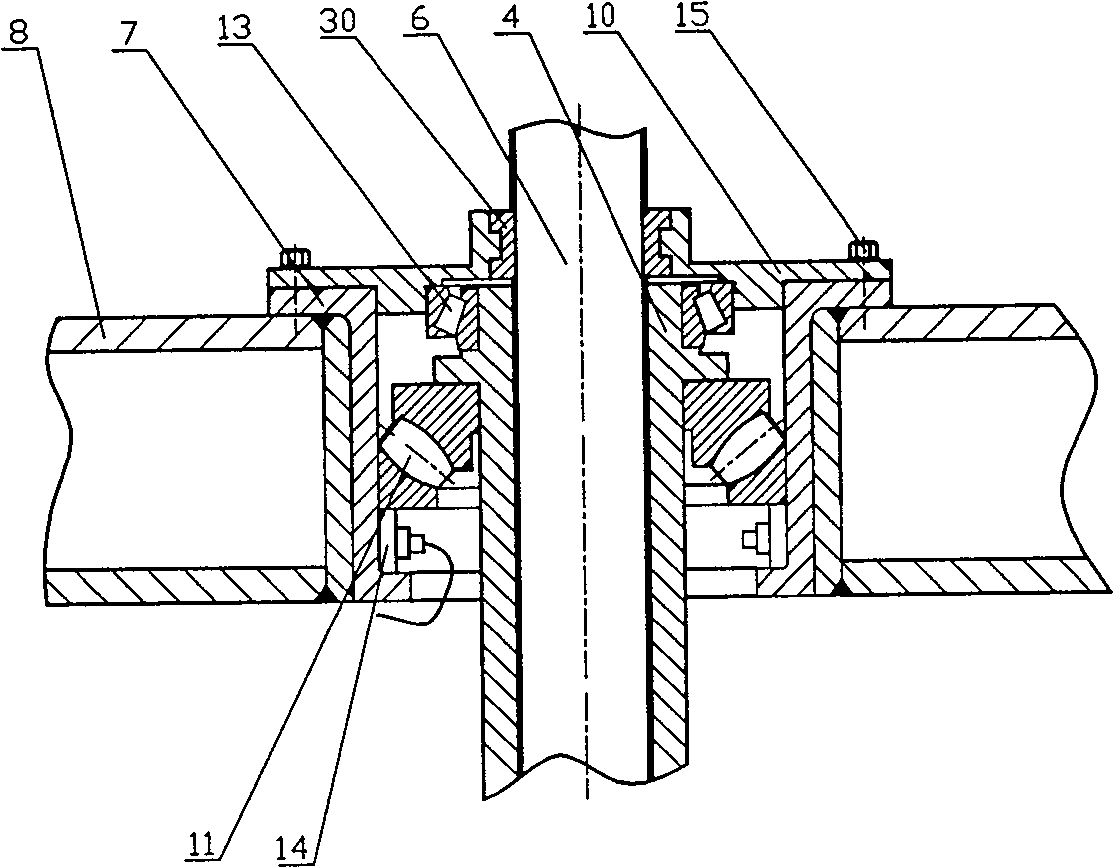

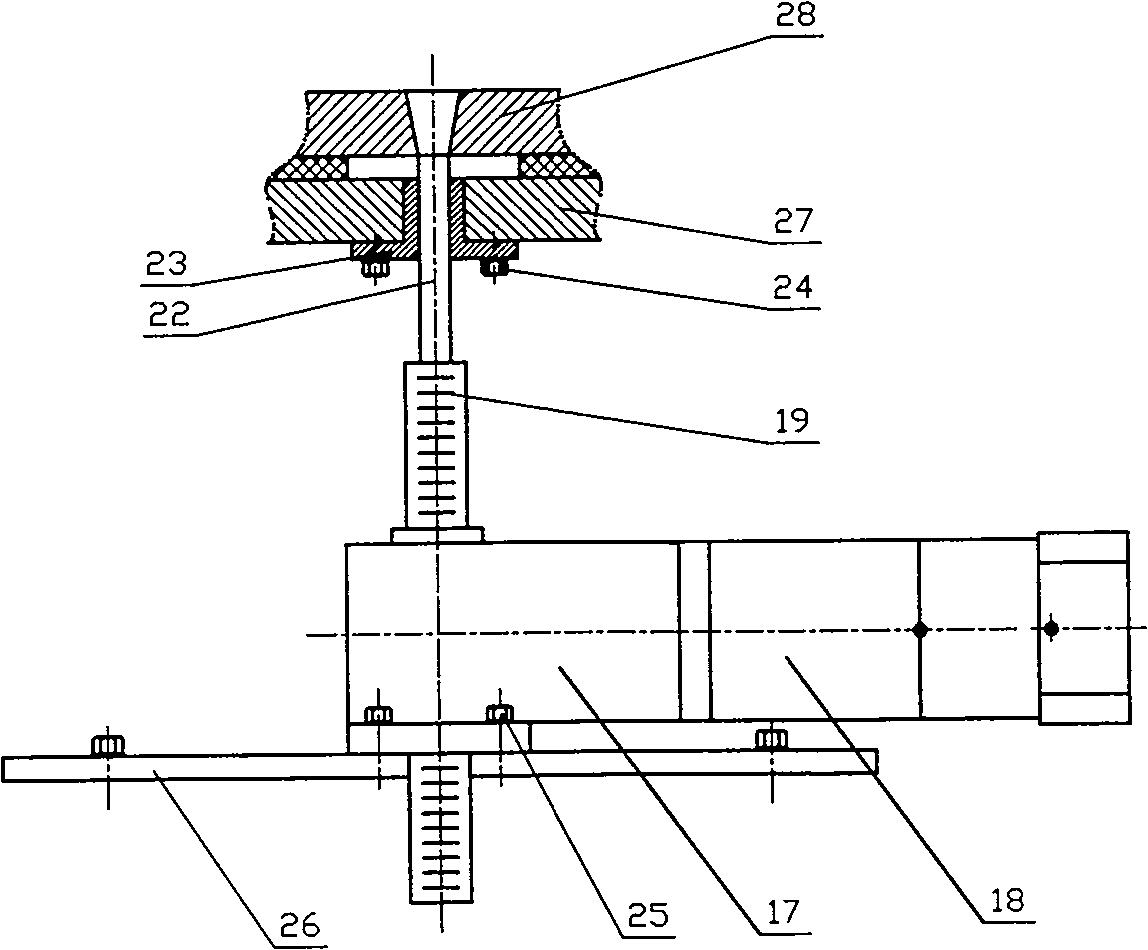

[0025] figure 1 It is a schematic diagram of the general structure principle of the all-electric mold clamping device of the rubber injection machine of the present invention. Including electric screw transmission system, bearing box and electric demoulding part. In the electric screw transmission system, there is a planar double-enveloping worm gear reducer 1, and a two-speed motor 2 with high starting torque is installed at the input shaft end of the reducer 1, and the output spindle of the reducer 1 is a hollow shaft 3, A drive nut 4 is installed in the inner hole, and the drive nut 4 is connected with the hollow shaft 3 with a flat key 5, and a main screw 6 is assembled in the center of the nut 4 . The ball head end of the main screw 6 cooperates with the ball head seat 9 installed on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com