Asparagus cutting device for vegetable processing

A technology of vegetable processing and asparagus, applied in metal processing, etc., to prevent cuts and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

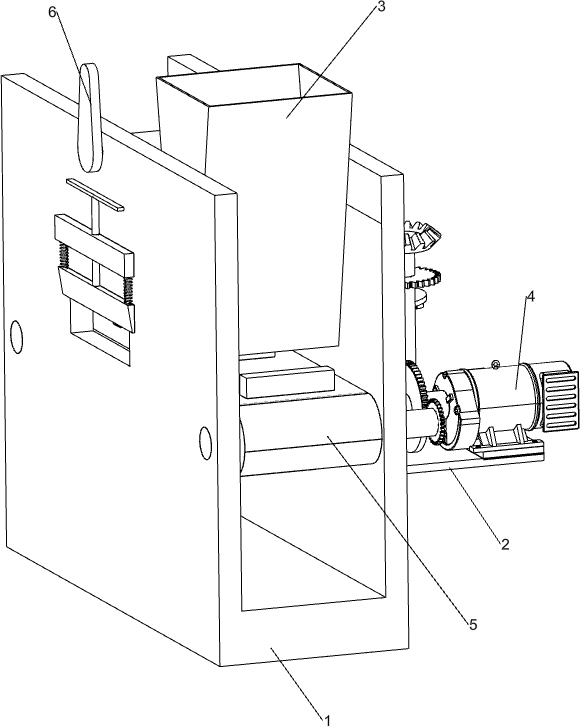

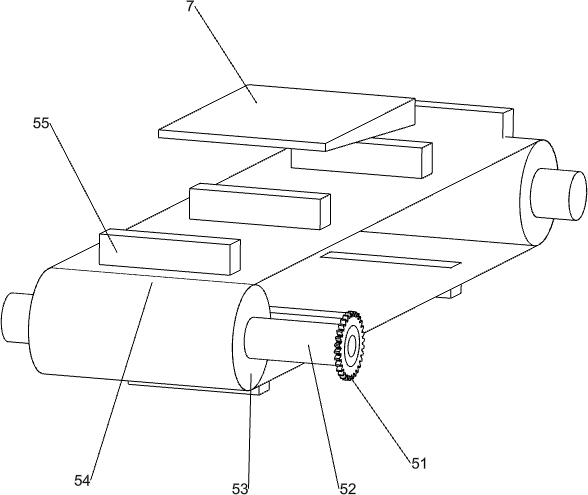

[0023] A device for cutting asparagus for vegetable processing, such as Figure 1-4 As shown, it includes a base 1, a support plate 2, a blanking box 3, a flattening mechanism 4, and a conveying mechanism 5. The right side of the base 1 is connected to the support plate 2, and the upper front side of the inner side of the base 1 is connected to the blanking box. 3. A flattening mechanism 4 is installed between the base 1 and the support plate 2 , a conveying mechanism 5 is installed on the base 1 , and the conveying mechanism 5 is connected to the bulldozing mechanism 4 through transmission.

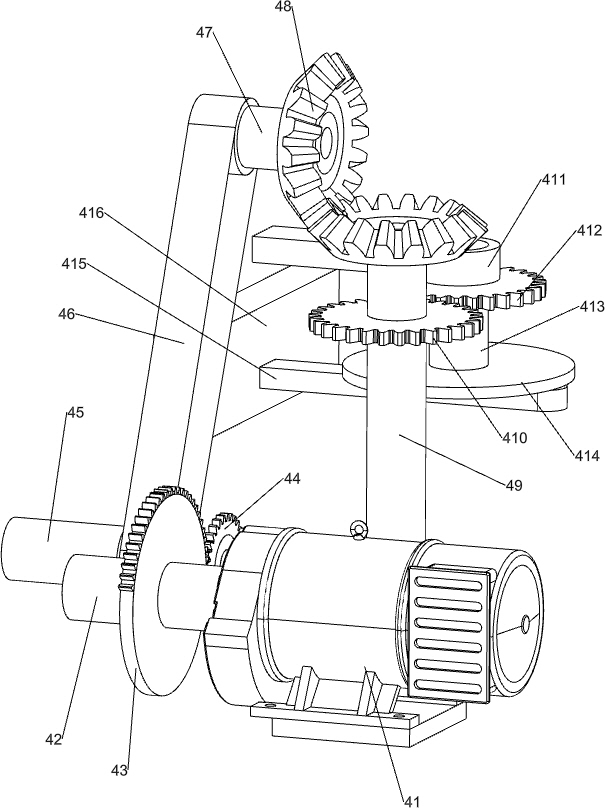

[0024] Pushing mechanism 4 includes servo motor 41, first transmission rod 42, first half gear 43, first gear 44, second transmission rod 45, belt transmission group 46, the third transmission rod 47, bevel gear 48, fourth Transmission rod 49, second gear 410, fixed guide sleeve 411, third gear 412, fifth transmission rod 413, transmission disc 414, sixth transmission rod 415 and push pl...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 , Figure 4 with Figure 5 Shown, also comprise cutting mechanism 6, and cutting mechanism 6 comprises the 5th gear 61, the 8th transmission rod 62, the 6th gear 63, the 2nd half gear 64, the 7th gear 65, the 9th transmission rod 66, cam 67 , transmission plate 68, the tenth transmission rod 69, the second limiting plate 610, blade 611 and spring 612, the fifth gear 61 is connected on the third transmission rod 47, the base 1 right side of the third transmission rod 47 rear side Rotationally connected with the eighth transmission rod 62, the eighth transmission rod 62 is respectively connected with the sixth gear 63 and the second half gear 64, the sixth gear 63 is located on the right side of the second half gear 64, the sixth gear 63 and the second half gear 64 The fifth gear 61 meshes, and the base 1 on the upper side of the second half gear 64 is rotatably connected with the ninth transmission rod 66, and the right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com