Polycarboxylate cement grinding aid and preparation method thereof

A technology of cement grinding aid and polycarboxylate, which is applied in the field of cement process additives to achieve the effects of small effective dosage, lower production cost, and reduced effective dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

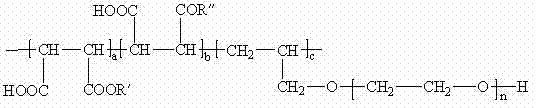

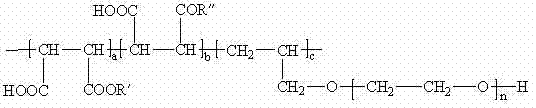

Image

Examples

Embodiment 1

[0044] Add 50 g of MA and 38 g of TEA into a four-necked flask, stir and raise the temperature to 80° C., and react for 3 hours to obtain a light yellow liquid which is small monomer A.

[0045] Dissolve 60 g of macromonomer APEG (molecular weight 1200) at 70°C and add it to a four-necked flask, and add H 2 O 79g, small monomer MA 5.1g, and above-mentioned synthesized small monomer A 10.8g, stir evenly, heat up to 72 ℃, at this moment add the initiator (NH 4 ) 2 S 2 o 8 3.1g, keep the temperature constant, react for 4 hours. Lower the temperature and add TEA solution (12.6g TEA dissolved in 12.6g H2 O) to neutralize to pH=7.0, control the final solid content of the solution to 50%, and the obtained yellow mucus is the polycarboxylate cement grinding aid.

Embodiment 2

[0047] Add 60 g of MA and 37.4 g of MEA into a four-necked flask, stir and raise the temperature to 80° C., and react for 3 hours to obtain a brownish-yellow liquid, which is small monomer A.

[0048] Dissolve 50 g of macromonomer APEG (molecular weight 1100) at 60°C and add it to a four-necked flask, and add H 2 O 64.6g, small monomer MA 4.5g, and above-mentioned synthetic small monomer A 10.1g, stir evenly, heat up to 72 ℃, at this moment, add the initiator (NH 4 ) 2 S 2 o 8 2.6g, keep the temperature constant, react for 4 hours. Lower the temperature, and add TEA solution (12.4g TEA dissolved in 15.0g H 2 O) to neutralize until pH = 7.5, control the final solid content of the solution to 50%, and the resulting yellow mucus is the polycarboxylate cement grinding aid.

Embodiment 3

[0050] Add 40 g of MA and 30.4 g of TEA into a four-necked flask, stir and raise the temperature to 80° C., and react for 3 hours to obtain a light yellow liquid which is small monomer A.

[0051] Dissolve 50 g of macromonomer APEG (molecular weight 1000) at 60°C and add it to a four-necked flask, and add H 2 O 65.3g, small monomer MA 4.9g, and the above-mentioned synthesized small monomer A 10.4g, stir evenly, heat up to 72°C, at this time, add the initiator Na into the flask twice 2 S 2 o 8 , add 1.6g (60% of the total amount of initiator) for the first time, react for 3 hours, add 1.1g (40% of the total amount of initiator) for the second time, react for 2 hours, cool down, and wait for the polymerization solution to cool to 40°C Add TEA solution (11.9g TEA dissolved in 14.6g H 2 O) to neutralize until pH = 7.0, control the final solid content of the solution to 50%, and the resulting yellow mucus is the polycarboxylate cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com