Keel frame for paving floor tiles

A technology of dragon skeleton and floor tiles, applied in the field of keel support frame, can solve the problems of unqualified cement stability, poor flatness control, increased floor bearing capacity, etc., to achieve flatness conveniently and quickly, shorten maintenance time, improve The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

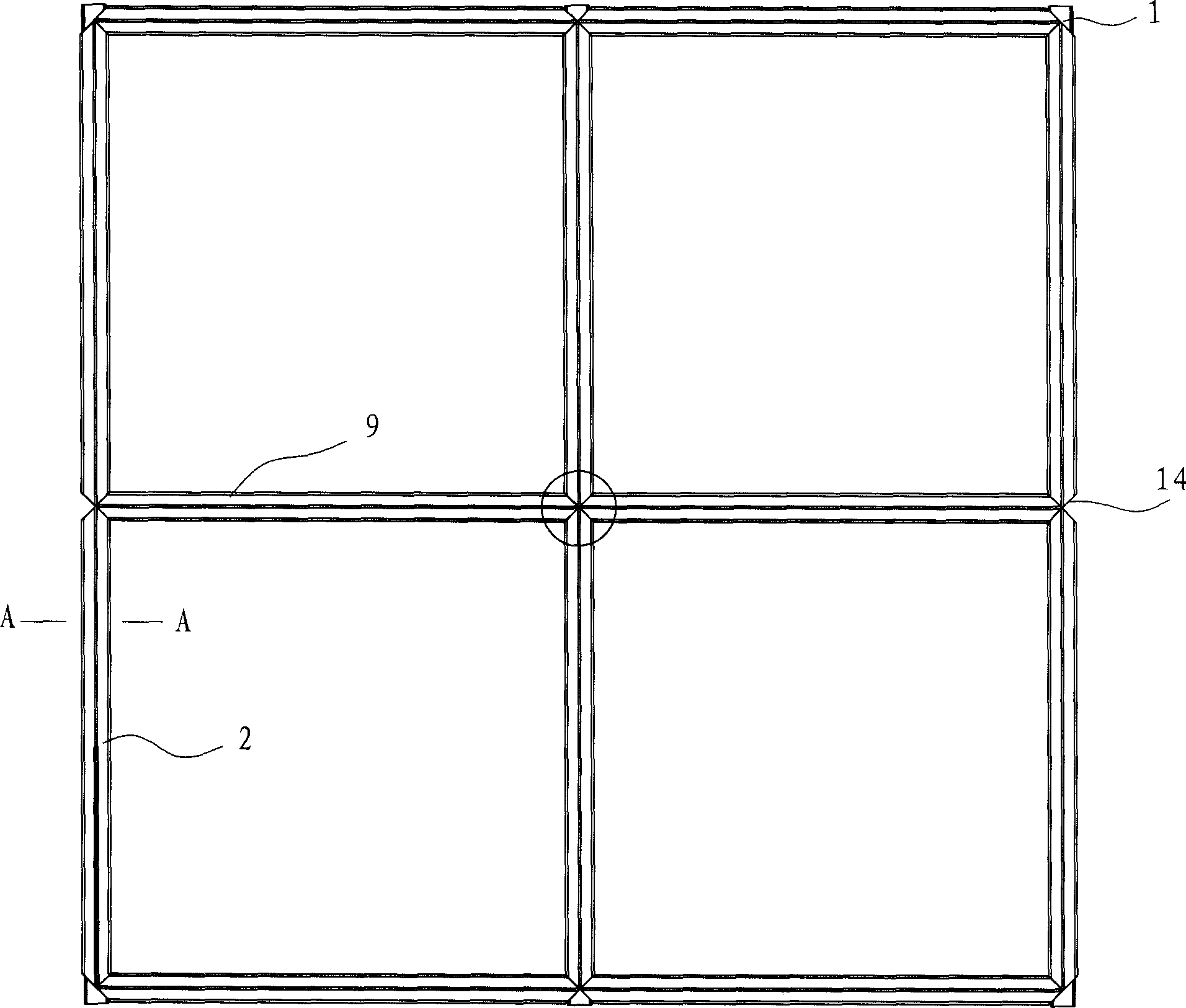

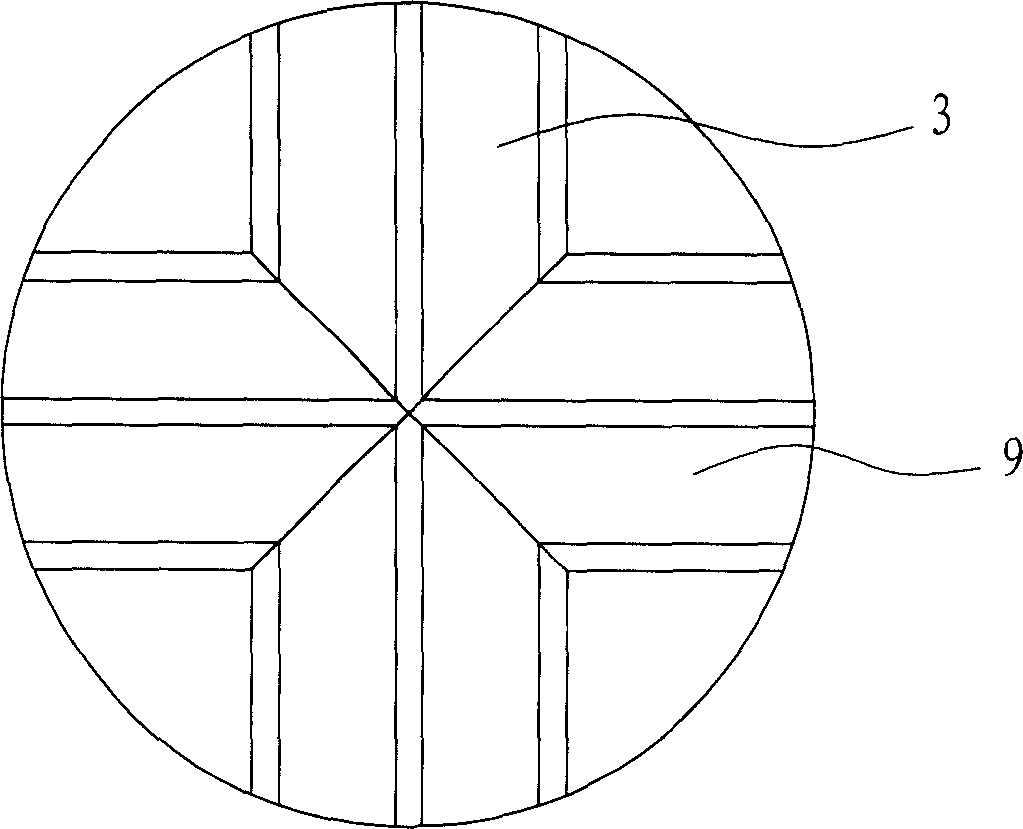

[0035] Embodiment one: see attached figure 1 To attach Figure 8 As shown, a keel frame for laying floor tiles is composed of longitudinal and transverse keels to form a frame structure. The longitudinal keel 3 is composed of a main keel 1, an auxiliary keel 2 snapped on the main keel 1, and fixedly connected to the bottom of the main keel 1. The main keel 1 is a U-shaped profile with an upward opening. The foot assembly includes a base and a level adjustment mechanism. The adjustment part 4 in the level adjustment mechanism passes through the opening on the bottom surface of the main keel. Extending into the main keel; the auxiliary keel 2 includes a horizontally arranged support part 5, a reinforcing rib 6 at the bottom and a partition bar 7 protruding outward at the top, and a downward bending part 8 is provided at the outer end of the support part 5 , is snapped and connected with the side wall of the main keel; the transverse keel 9 includes a support portion 10 arranged h...

Embodiment 2

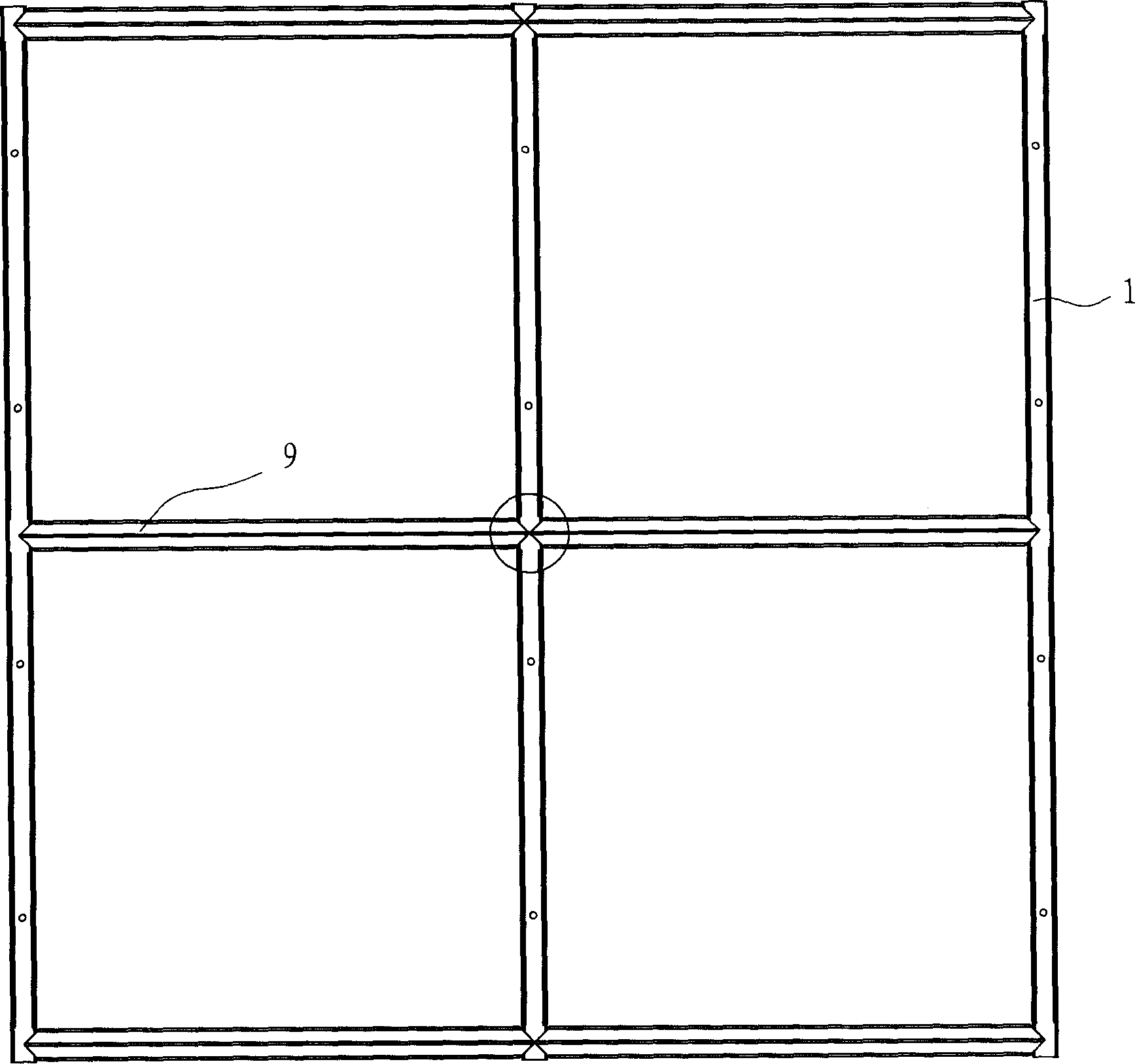

[0037] Embodiment two: see attached Figure 9 to attach Figure 10 As shown, a keel frame for laying floor tiles is composed of longitudinal and transverse keels to form a frame structure. The longitudinal keel is composed of a main keel 1, an auxiliary keel clamped on the main keel 1, and a plurality of fixedly connected bottoms of the main keel 1. The main keel 1 is a U-shaped profile with an upward opening. The foot assembly includes a base and a level adjustment mechanism. The adjustment part 4 in the level adjustment mechanism extends to the Inside the main keel; the auxiliary keel includes a horizontally arranged support part, a reinforcing rib at the bottom, and a partition bar protruding outward from the top. The transverse keel 9 includes a support part arranged horizontally, a reinforcing rib arranged at the bottom along the extending direction, and a partition bar protruding outward at the top, and slots for snap-fitting with the side walls of the main keel are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com