High intensity lightweight honeycomb core and production method thereof

A manufacturing method and technology of honeycomb core, applied in chemical instruments and methods, lamination auxiliary operation, lamination and other directions, can solve the problems of arched plate, easy to be damp, limited application, etc., to overcome poor temperature control, not easy to be damp, The effect of a large amount of wealth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

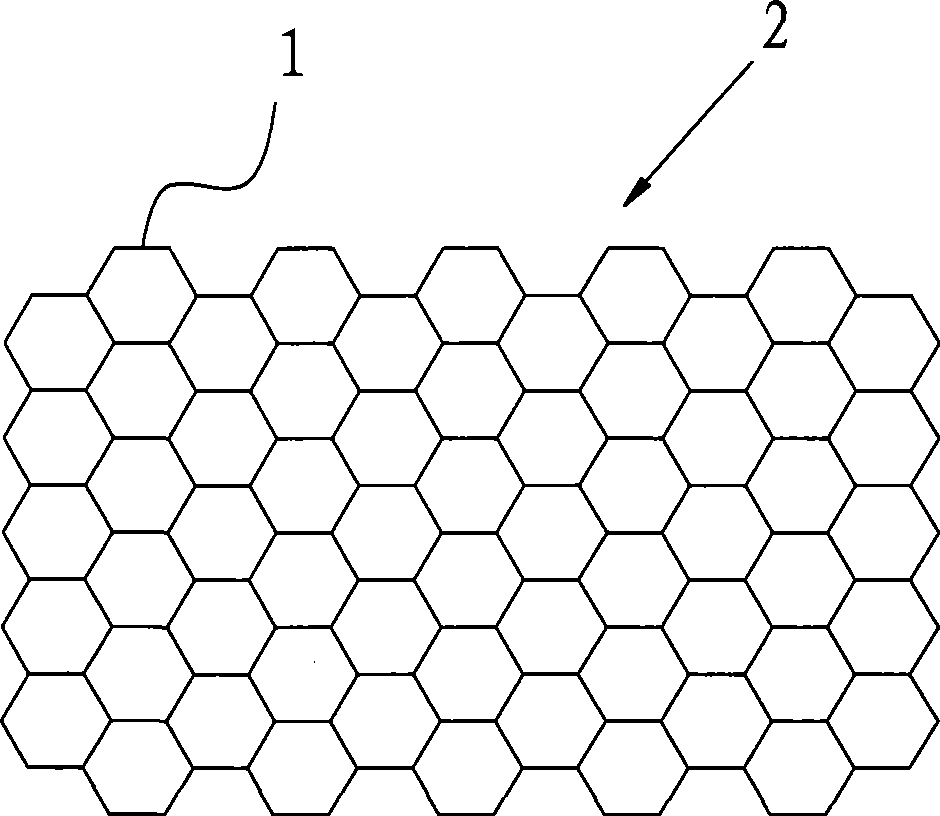

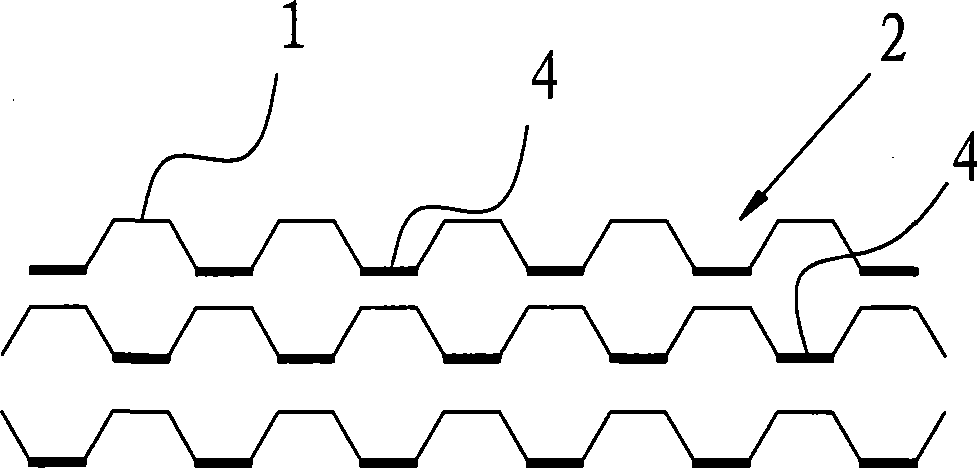

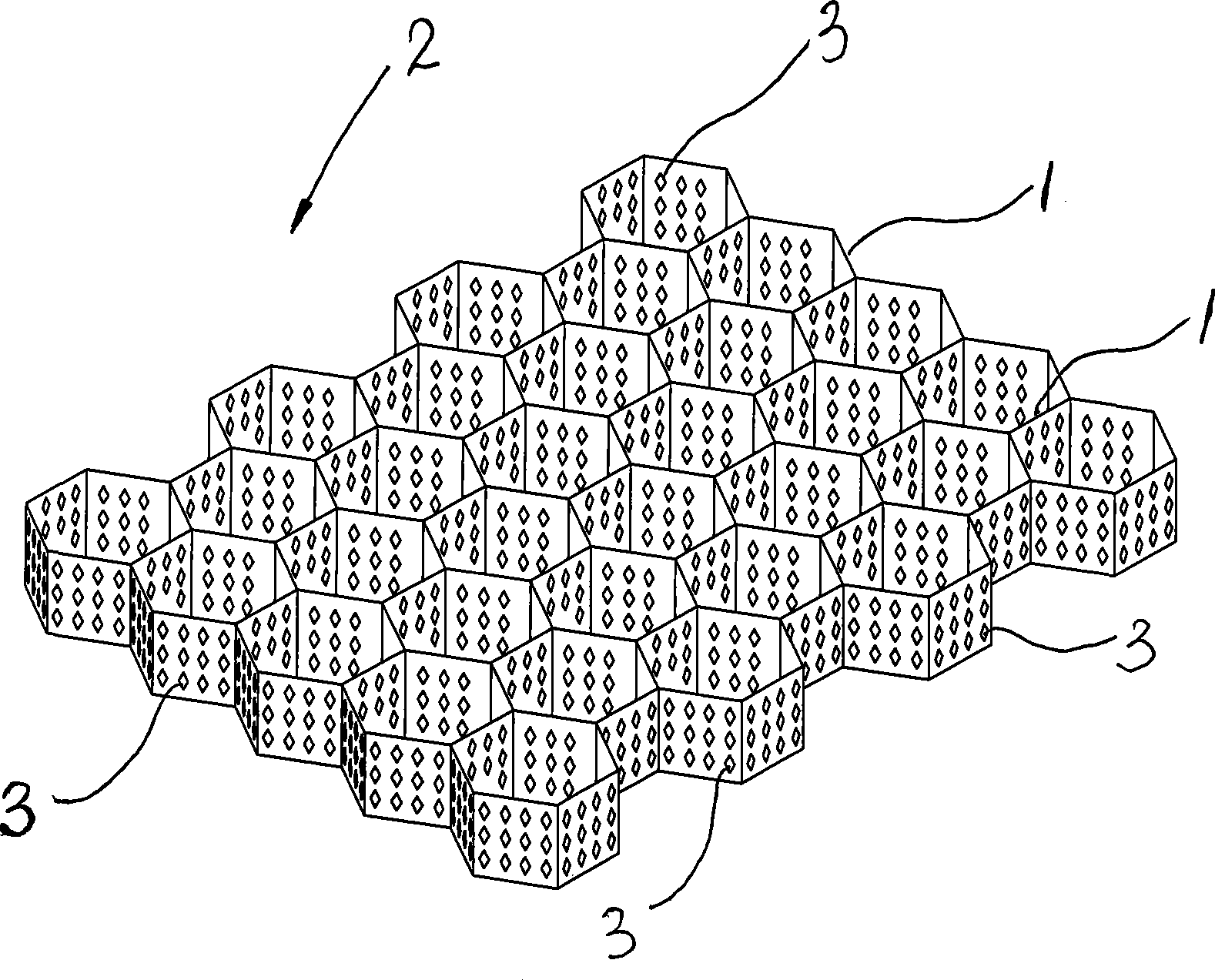

[0030] as attached figure 1 And attached figure 2 A high-strength lightweight honeycomb core is shown, which includes a honeycomb core 2 composed of a plurality of plates 1, and a plurality of diamond-shaped holes 3 are evenly distributed on the plate 1, and the two adjacent The distance between the diamond-shaped small holes 3 is 8mm.

[0031] The thickness of the board 1 is 0.01mm-0.08mm. The height of the honeycomb core formed by combining the plurality of plates 1 is 2-90 mm.

[0032] The plate 1 is an aluminum alloy plate, the composition and weight ratio of the aluminum alloy plate are: 0.6% Si, 0.7% Fe, 0.8% Ti, 0.085% Cu, 1.5% Mn, 0.05% Zn, the rest is aluminum, which increases the physical and chemical properties of the alloy aluminum plate, and overcomes the shortcomings of the original honeycomb aluminum plate that is easy to deform due to thermal expansion and cold contraction. Because the aluminum honeycomb plate 1 has pinholes, the entire aluminum honeycomb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com