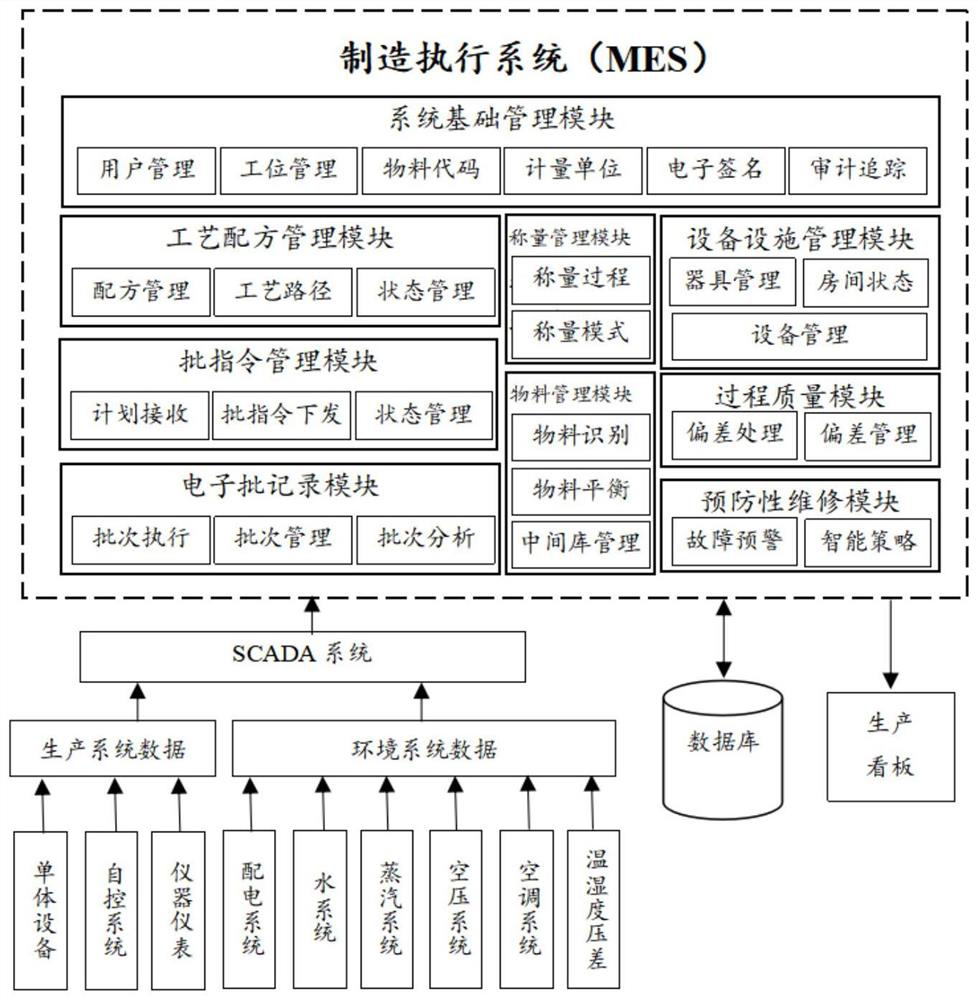

Method for producing formula food for special medical purposes by using manufacturing execution system

A manufacturing execution system and formula food technology, applied in manufacturing computing systems, neural learning methods, data processing applications, etc., can solve the lack of preventive maintenance functions, non-compliance, and the inability to achieve customized product process routes and complete product production. Periodic management and control and other issues to achieve the effect of reducing the number of emergency shutdowns, ensuring stable production, and ensuring effectiveness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0172] Example: Establish a preventive maintenance model for the motor of a certain production equipment

[0173] First, the SCADA system is used to collect the parameter signals of the motor in real time, and a training sample library is established. The parameter signal here refers to the power, current, voltage, shaft temperature, and vibration signal of the motor under normal use.

[0174] Secondly, the BP neural network is used to train samples to establish a fault prediction model.

[0175] Thirdly, when the performance of the motor begins to decline, the MES system judges through the fault prediction model, displays early warning information in time, and provides maintenance strategies to guide the operator in maintenance.

[0176] The motor preventive maintenance model improves the stability of equipment operation, reduces the number of emergency shutdowns of equipment, and can effectively ensure the stable production of the workshop.

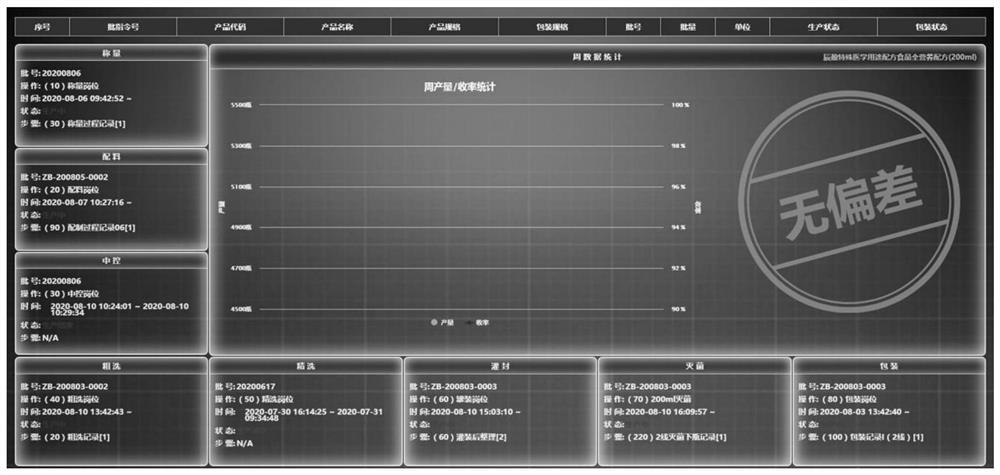

[0177] Such as Figure 11 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com