Preparation method of water used for oilfield flooding, water flooding and water gathering

An oilfield water injection and polymer injection technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing membrane area, low viscosity of polymer solution, and increasing land occupation Area and other issues, to achieve the effect of reducing the amount of use, improving the efficiency of polymerization, and reducing the area occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

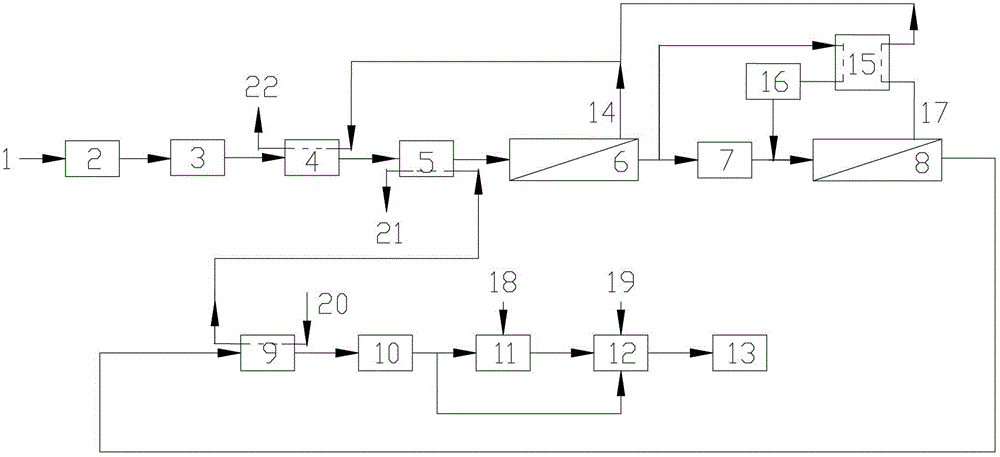

Image

Examples

Embodiment 1

[0024] The sea water temperature of the present embodiment is 2 ℃, concrete steps are:

[0025] In the first step, the seawater 1 is sterilized and algae-killed through the electrolytic chlorine production device 2;

[0026] In the second step, a self-cleaning filter 3 with a specification of 50 μm is used to remove suspended particles and some algae with a particle size of 50 μm or more in seawater, so as to filter seawater;

[0027] In the third step, the filtered seawater enters the titanium plate type primary preheater 4, and conducts countercurrent flow heat exchange with the nanofiltration concentrated water and ultrafiltration concentrated water, recovers the heat of the nanofiltration concentrated water, raises the seawater temperature to 8°C, and recovers heat The subsequent nanofiltration concentrated water is directly discharged;

[0028] In the fourth step, the preheated seawater enters the titanium plate type secondary preheater 5, and conducts countercurrent hea...

Embodiment 2

[0035] The sea water temperature of the present embodiment is 22 ℃; According to the step of embodiment 1, wherein different points are explained as follows:

[0036] The third step can be canceled.

[0037] In the fourth step, the seawater enters the titanium plate type secondary preheater 5, and conducts countercurrent heat exchange with the produced water to further increase the temperature of the raw water to 32°C;

[0038] In the fifth step, the seawater enters the ultrafiltration device 6, which uses a PP ultrafiltration membrane with a molecular weight cut-off of 80,000 Daltons to obtain ultrafiltration water; the water recovery rate of the ultrafiltration device is 93%. The average SDI of the ultrafiltration product water is 3.0, and the average turbidity is 0.1NTU;

[0039] In the sixth step, 45% of the ultrafiltration product water is directly transported by the high-pressure pump 7 into the nanofiltration device 8, and the rest of the ultrafiltration product water ...

Embodiment 3

[0044] The sea water temperature of the present embodiment is 3 DEG C, according to the steps of embodiment 1, wherein the differences are explained as follows:

[0045] In the third step, after the seawater passes through the primary preheater 4, the temperature is increased to 8°C;

[0046] In the fourth step, after the seawater passes through the secondary preheater 5, the temperature rises to 28°C;

[0047] In the fifth step, the ultrafiltration membrane adopts a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20,000 Daltons, and the operating pressure of the ultrafiltration device 6 is 0.08MPa;

[0048] In the sixth step, the nanofiltration membrane adopts a membrane element with a rejection rate of less than 60% for divalent cations. The sulfate content in the nanofiltration product water is 68mg / L, the total content of calcium and magnesium ions is 400mg / L, and the salinity is 16020mg / L ;

[0049] In the seventh step, the nanofiltration wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com