Full-digital anhydrous glazing line

A digital and ink technology, applied in the field of full digital anhydrous glazing line, can solve problems such as easy damage, thin and uniform glazing, and discounted value, so as to avoid material waste and ensure stable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

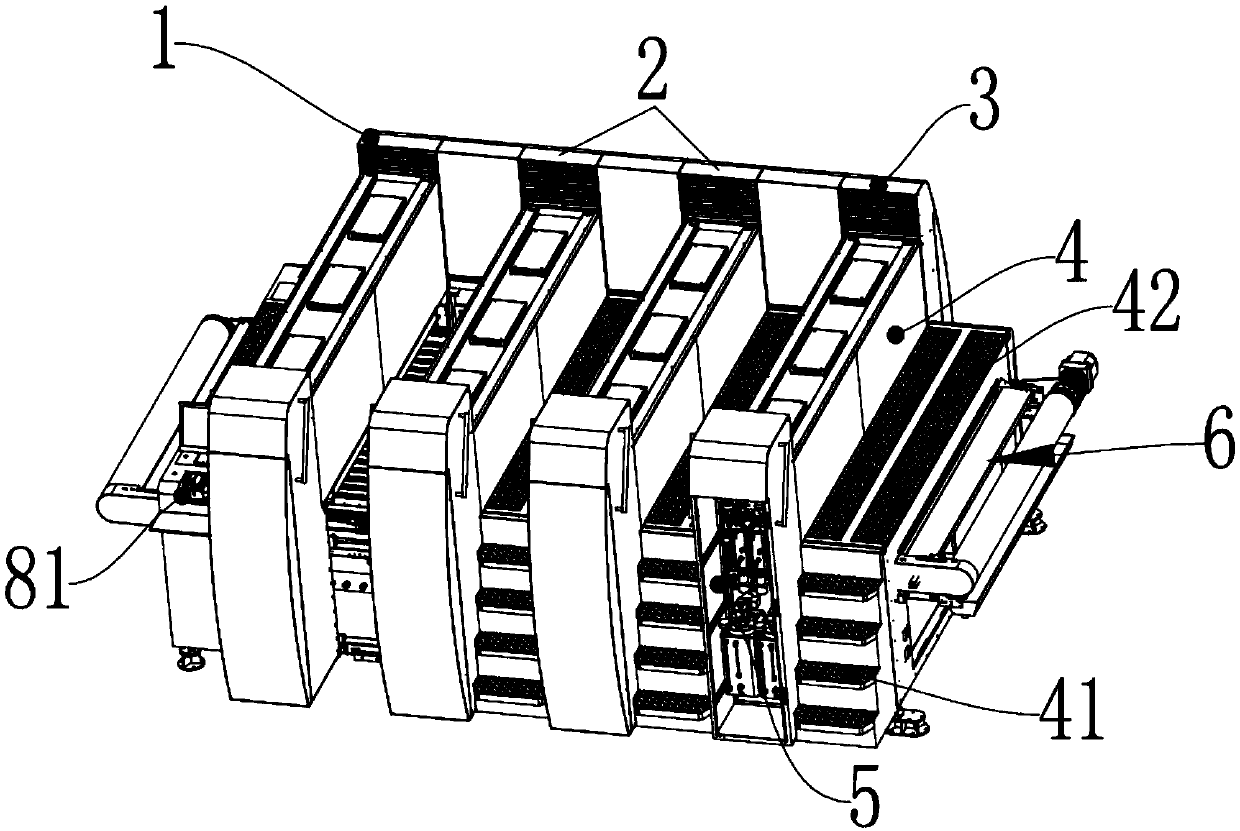

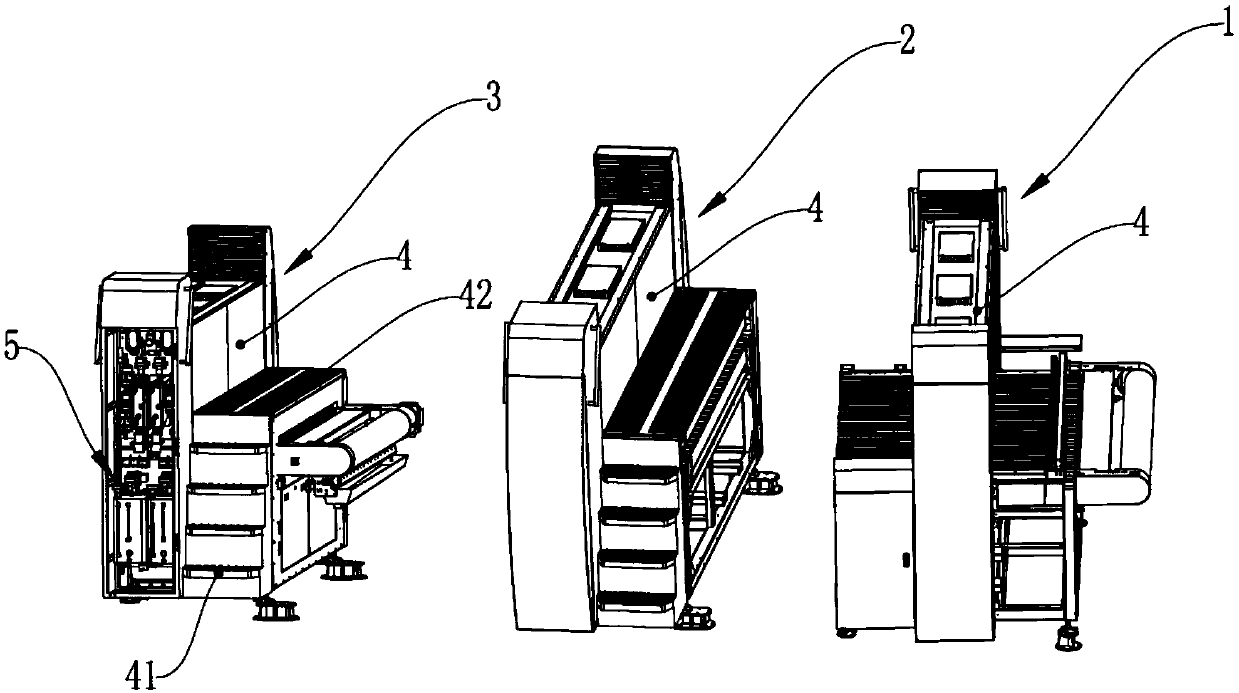

[0055] A fully digital waterless glazing line, including three sets of ceramic slab inkjet machines connected in series, the first set of ceramic slab inkjet machines for digital surface glaze printing, and the second set of ceramic slab inkjet machines for basic ink Printing, the third group of inkjet machines for functional glaze printing.

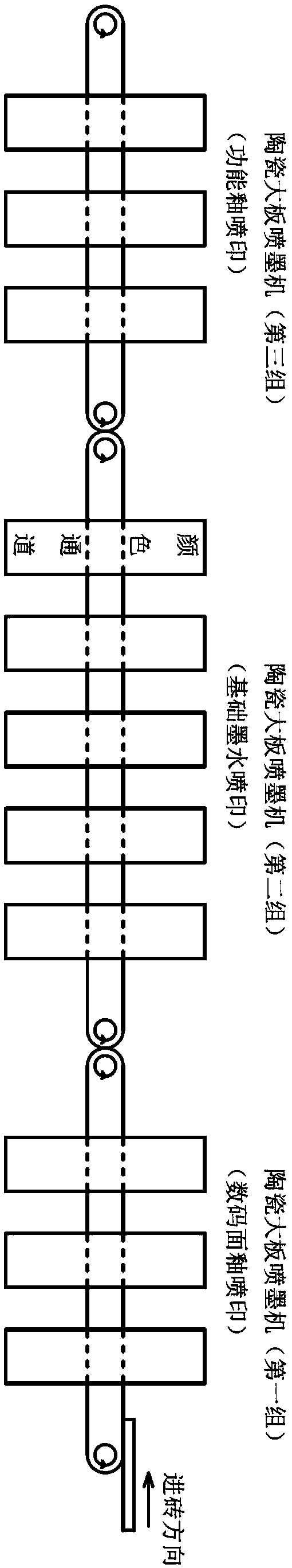

[0056] Digital spray glaze uses glaze as the solute to disperse in organic solvents to form a stable suspension, which is applied to the surface of tiles through the printing nozzle, showing richer and finer texture and color effects. Such as figure 1 , the waterless glazing line is realized through the series connection of three ceramic large-plate inkjet machines, and the basic glaze, color ink, and functional ink can be combined arbitrarily.

[0057] And it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com