Automatic foam discharging ball filling device and method

A technology of automatic filling and soaking volleyball, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as unpredictable accidents, difficult maintenance, complex structure, etc. Mining requirements, ease of installation and maintenance, and the effect of maintaining stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

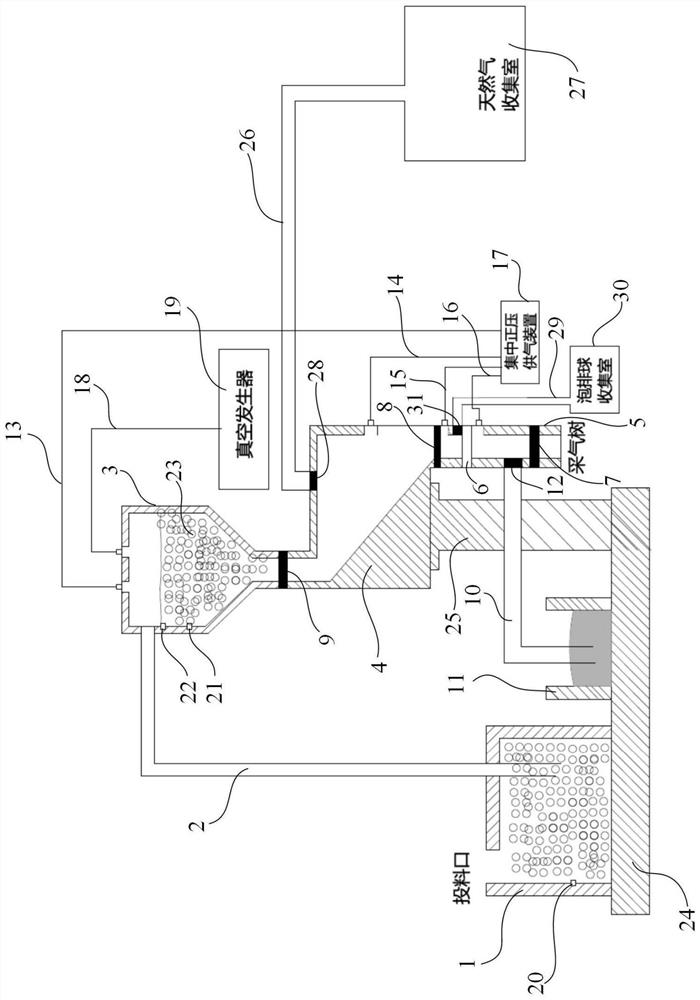

[0041] like figure 1 As shown, the bubble volleyball automatic filling device provided in this embodiment includes a storage mechanism, a transmission mechanism and an exhaust gas processor 11 . The storage mechanism includes a silo 1 and a storage chamber 3 . The conveying mechanism includes a dehydration chamber 4 communicated with the material storage chamber, and an air filter chamber 5 communicated with the dehydration chamber 4 . The input end of the filter chamber 5 is communicated with the Christmas tree. The silo 1 and the waste gas processor 11 are installed on the base 24 ; the dehydration chamber 4 is installed on the base 24 through the support column 25 .

[0042] The storage chamber 3 is located above the storage bin 1 and the dehydration chamber 4 , and the storage chamber 3 communicates with the storage bin 1 through the feeding pipeline 2 . The top of the material storage chamber communicates with the centralized positive pressure air supply device 17 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com