Filter

A filter and filtrate technology, applied in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of reducing the amount of catalyst, decreasing production capacity, accumulating filters, etc., to maintain stable production, Avoid fluctuations and maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

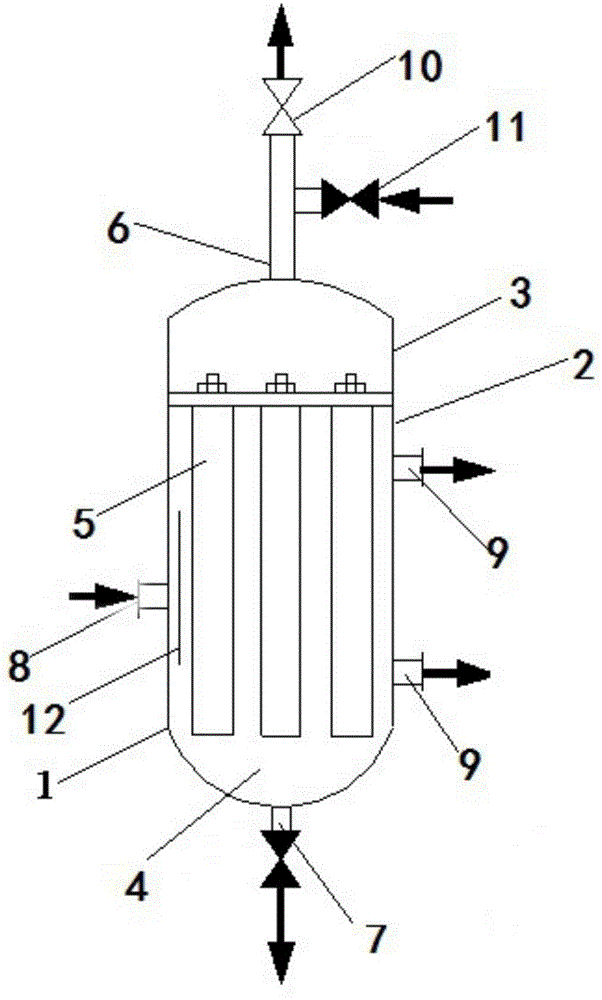

[0034] Such as figure 1 As shown, a filter 1 of the present invention, the filter 1 includes a cylinder body 2, an upper head 3 and a lower head 4; the cylinder body 2 is provided with a filter element 5, and the outer wall of the cylinder body 2 There is a circular tube;

[0035] The upper part of the cylinder body 2 is provided with an upper head 3, and the top of the upper head 3 is provided with a filtrate discharge / recoil liquid inlet 6; the filtrate discharge / recoil liquid inlet 6 is the same port ;

[0036] The bottom of the cylinder body 2 is provided with a lower head 4, and the lower head 4 is provided with a discharge port 7;

[0037] The side wall of the cylinder 2 is provided with a reaction circulation liquid inlet 8 and a reaction circulation liquid outlet 9;

[0038] The filtrate discharge / backflush inlet 6 is connected to the regulating valve 10 and the backflush valve 11 respectively;

[0039] The reaction circulation liquid outlet 9 is one or more; the a...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is that there are three reaction circulation liquid outlets 9 , and the reaction circulation liquid outlet 9 and the reaction circulation liquid inlet 8 are evenly distributed on the same circumference of the cylinder 2 . The circumferential position is half the length of the cylinder body 2 .

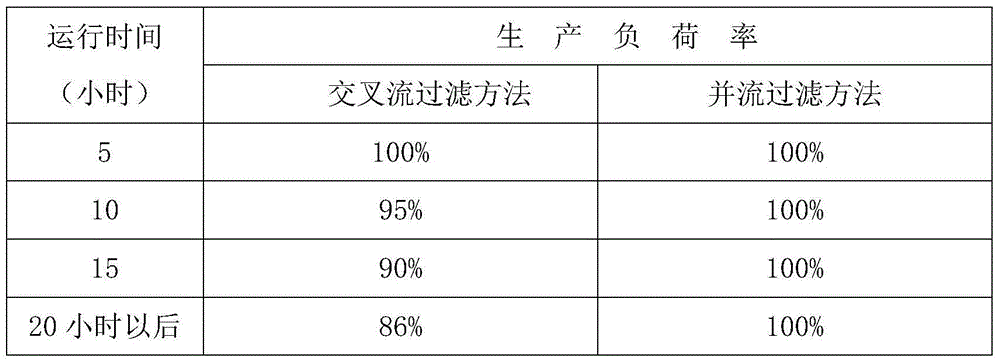

[0057] Table 1 shows the change of the production load rate of the cross-flow filtration method and the co-flow filtration method under the same conditions as the operating time of the device increases. It is not difficult to see the accumulation of the catalyst in the filter 1. Under the same reaction conditions, the accumulation of the catalyst in the filter 1 can be known from the reduction of the production load rate.

[0058] Table 1

[0059]

[0060] From the comparative comparison in Table 1, it can be seen that the co-current filtration method can effectively prevent the accumulation of catalyst in the filter 1, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com