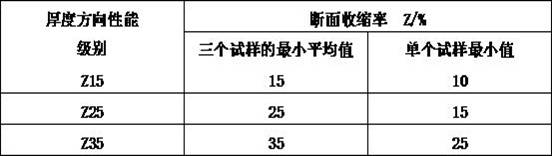

Method for improving Z-direction performance of Q390E thick plate with thickness of 50-80mm

A performance and plate technology, applied in the field of improving the Z-direction performance of Q390E thick plates with a thickness of 50-80mm, can solve the problems of long production cycle, unfavorable batch supply, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Example: steel type Q390EZ35, slab thickness 250mm, pre-desulfurization treatment of molten iron→converter→LF+RH refining→250mm thick slab→heating→controlled rolling and controlled cooling→stack cold rolling to make 50~80mm medium plate, quantity 8 The tonnage is 121.3 tons, including 4 pieces of 50mm and 4 pieces of 80mm.

[0014] 1. Melting composition: C 0.085%; Mn 1.46%; Si 0.20%, S 0.0032%, P≤0.010%, Als0.028%, Nb 0.030%, Ti 0.04%.

[0015] 2. Converter tapping ladle slag washing, adding 8kg / t high-alkalinity synthetic slag, the composition of the synthetic slag contains by weight percentage: 60%≤CaO≤70%, BaO 15-20%, 02 ≤3.0%, 02 o 3 ≤4.5%, 2.0%≤Na 2 O≤4.1%, CaF2≤7.5%, MgO≤4%. Synthetic slag is added in two times, 1 / 3 of the total amount of synthetic slag is added to the ladle before tapping, and the alloy and deoxidizer are included in 1 / 4 of tapping, until 3 / 4 of tapping is completely added.

[0016] 3. The slab has a good low-magnification structure, with cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com