Method for precisely determining coal injection rate during blowing-down and blowing-in periods of blast furnace

A technology of coal injection and blast furnace, which is applied to blast furnaces, blast furnace details, furnaces, etc., and can solve problems such as the inaccurate calculation of blast furnace coal shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

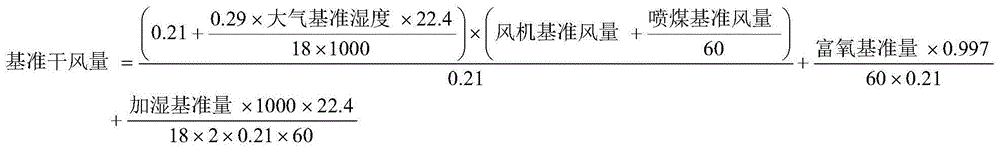

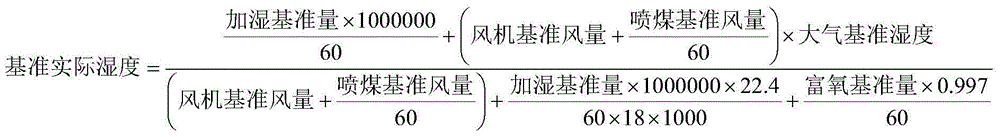

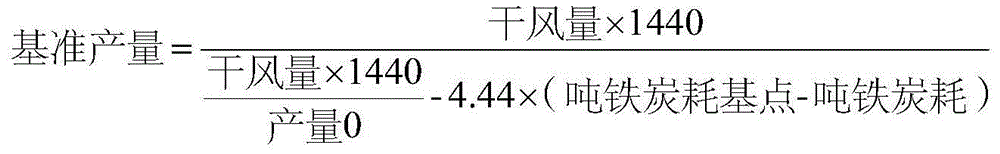

Method used

Image

Examples

Embodiment 1

[0034] At 7:00 on a certain day, the fan supplies air with an air volume of 1000m 3 / min, at 8:00 the air release valve is closed, that is, the air volume enters the blast furnace, and the atmospheric humidity is 8g / m at this time 3 , humidification steam 1t, oxygen enrichment volume is 0, and the air volume has been increased to 3000m by 9:00 3 / min, there is no coal injection before 9:00, the target coal ratio is 180kg / tfe, and the fuel ratio is 530kg / tfe, so how much coal is missing from 8:00 to 9:00? Conditions Pulverized coal contains 70% carbon, and coke contains 87% carbon. The process is as follows:

[0035] 1. Execute the steps (1) to (4) of the plan, and count the coal ratio, fuel ratio, output, air oxygen volume, humidification, etc. during normal production. If the average value of four days of normal production is counted: the air volume is 6600m 3 / min, oxygen enrichment 20000m 3 / h, humidification 3t / h, coal injection wind 5000m 3 / h, coal ratio 200kg / tfe, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com