Hot extrusion mold for small-sized aluminum alloy round tube

A technology of hot extrusion die and aluminum alloy, applied in the direction of metal extrusion die, metal extrusion mandrel, etc., to ensure stable production and solve the effect of easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

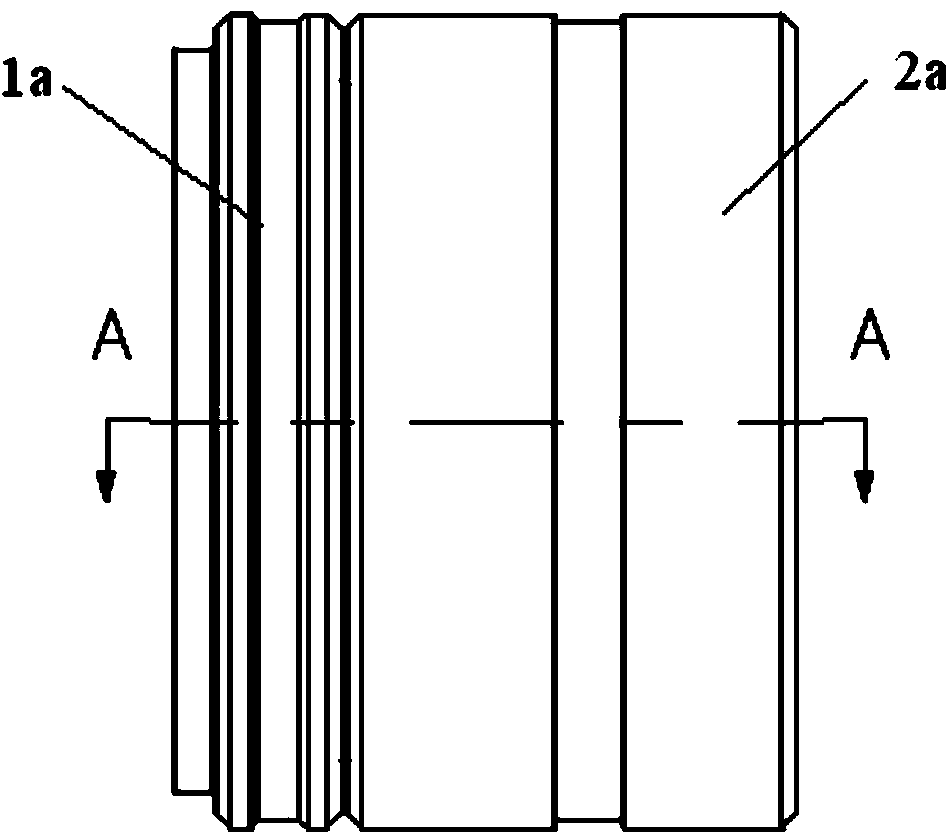

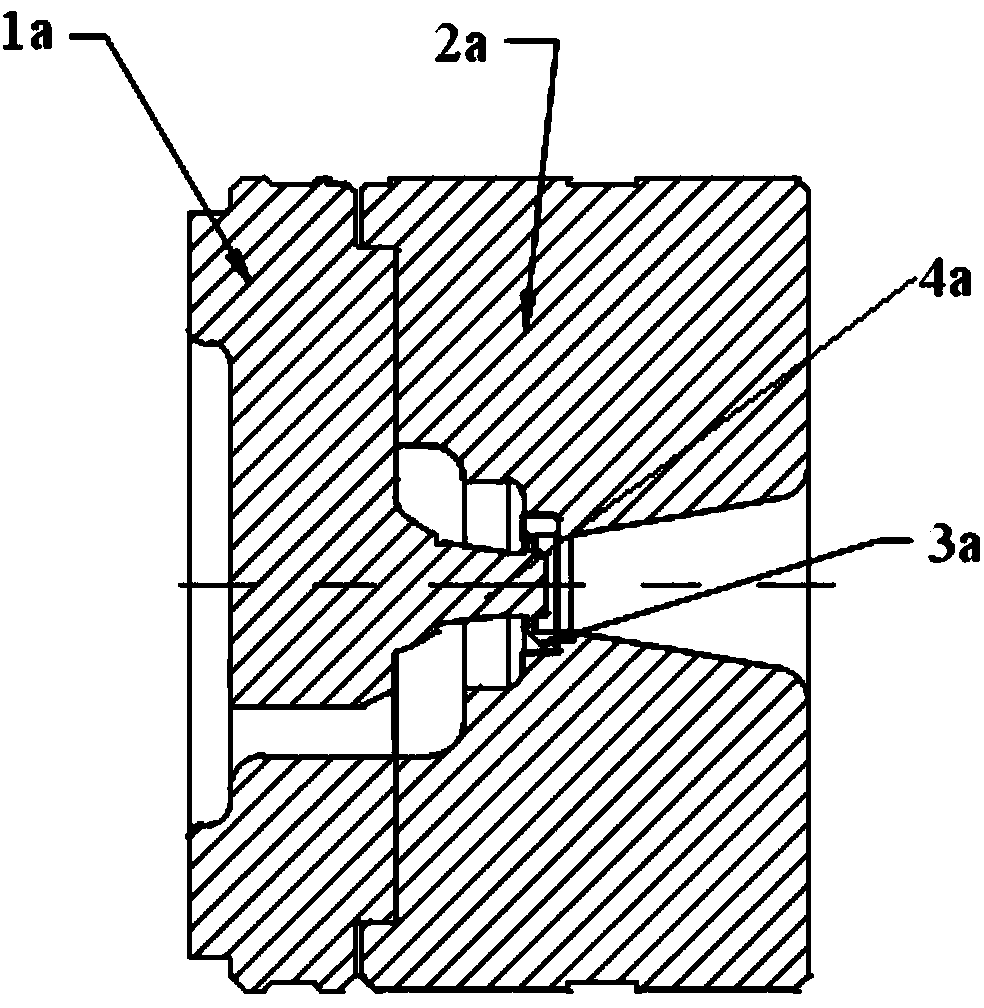

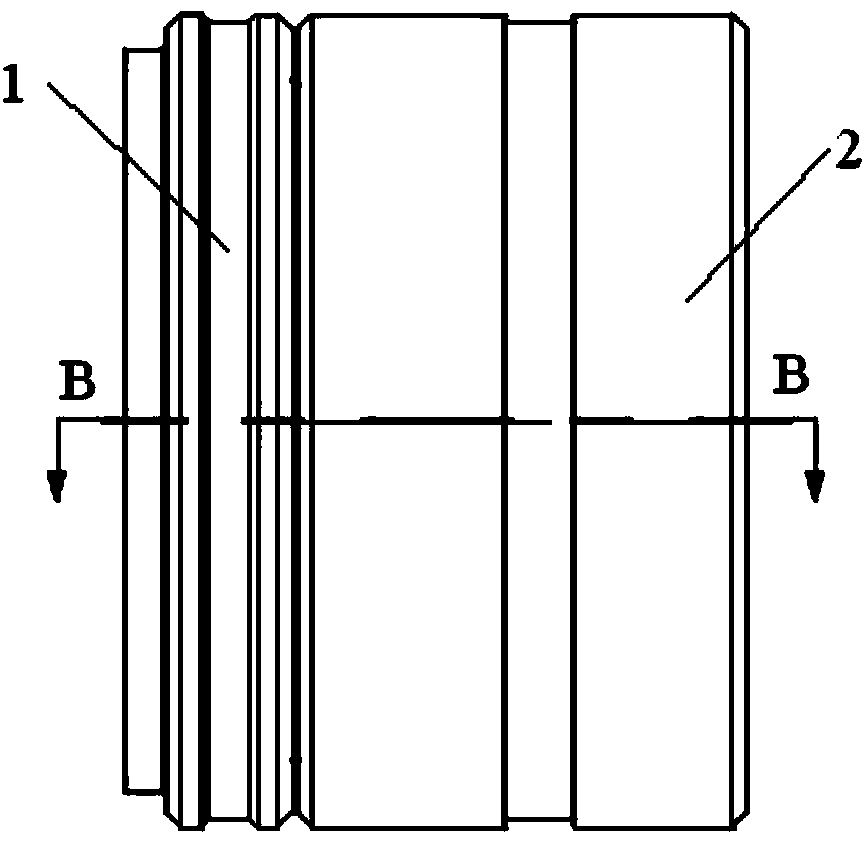

[0016] like Figure 3 ~ Figure 8 Shown: the small-sized aluminum alloy round tube hot extrusion die upper mold 1, lower mold 2, upper mold core 3, lower mold core 4, through hole 5, pressure relief ball 6, core head working belt 7, etc.

[0017] like image 3 , Figure 4 Shown, the present invention comprises upper mold 1 and lower mold 2, and lower mold core 4 is set in the lower mold 2 cavity; As Figure 5 , Image 6 As shown, the center of the upper mold 1 is provided with a through hole 5, and the upper mold core 3 is embedded in the through hole 5; as Figure 7 , Figure 8 As shown, one end of the upper mold core 3 is provided with a pressure relief ball 6, and the other end of the upper mold core 3 is a core head working belt 7, and the core head working belt 7 is in the inner cavity of the lower mold core 4, and is connected with the lower mold core. The core 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com