Composite red mud depositing separating washing method and tank

A settling separation and settling tank technology, which is applied in settling tanks, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problems of large hydrolysis loss, long material residence time, and poor buffering, so as to reduce filtration Section, reduce production costs, the effect of production stability and optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

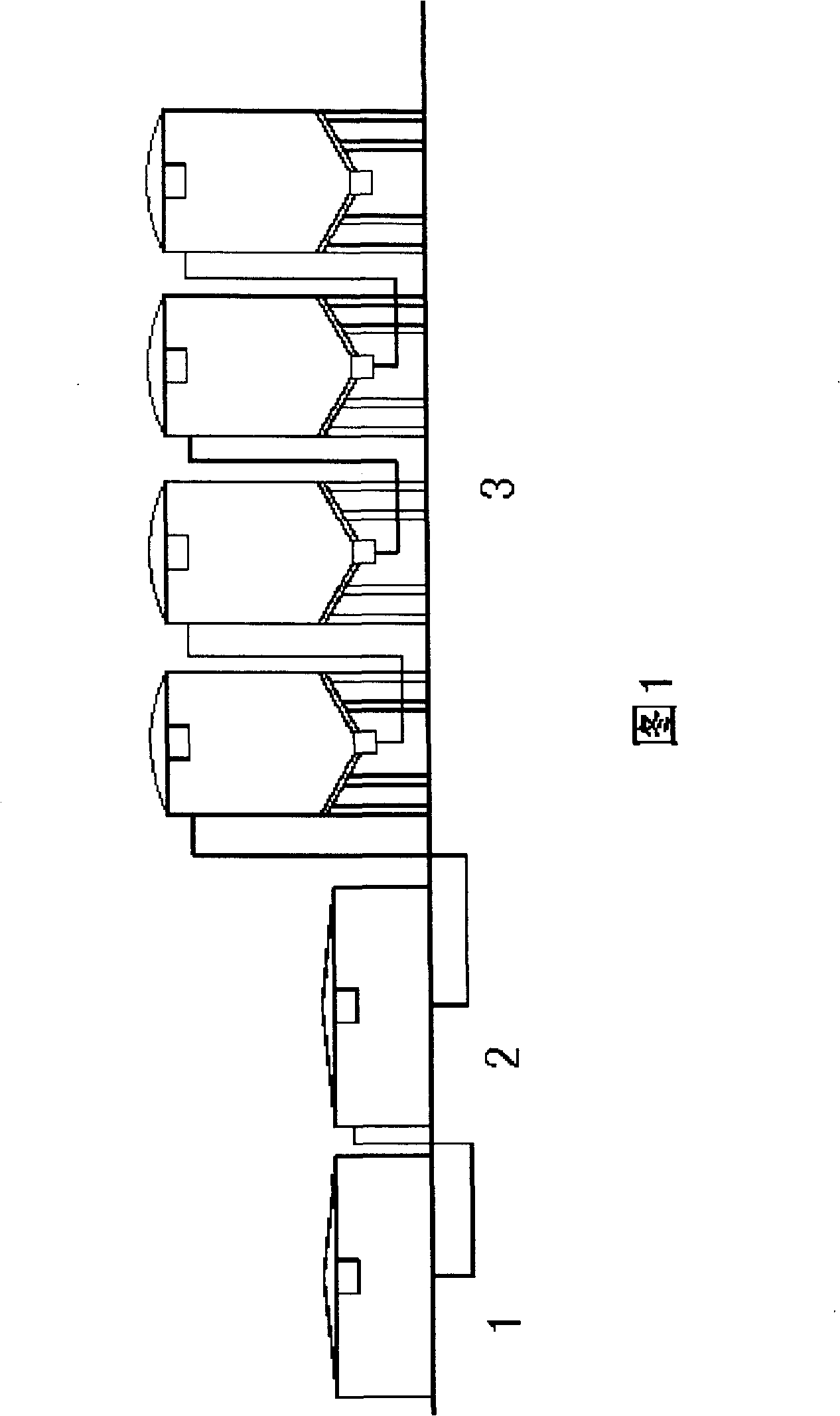

[0011] Embodiments of the present invention: the present invention adopts two flat-bottomed settling tanks as separate settling tanks (1) and public settling tanks (2) respectively, and four high-efficiency settling tanks are connected behind as washing settling tanks (3), and the dissolved slurry After dilution, it enters the separation and settling tank (1) for separation, the overflowed sodium aluminate solution is sent to the subsequent section for processing, and the red mud flowing out of the bottom enters the washing and settling tank (3) for washing, and the washed red mud is directly Sent to the red mud dam for stockpiling, when the separation settling tank (1) or the washing settling tank (3) needs to be overhauled, the public settling tank (2) then replaces their work respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com