Calibration method of side guide plate of finishing mill

A calibration method and side guide plate technology, applied in the field of steelmaking, can solve problems such as unguaranteed plate shape, unstable rolling of strip steel, and large moderate deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with embodiment:

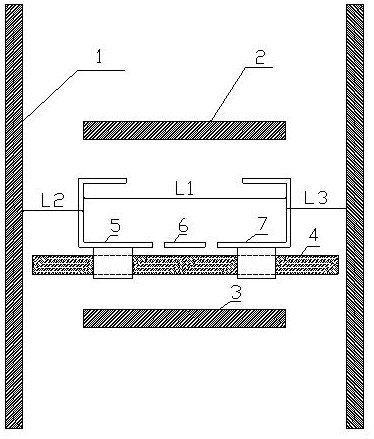

[0008] A calibration method for a side guide plate of a finishing mill, characterized in that: the equipment involved in the calibration method includes a frame archway 1, an upper entrance guide 2, an entrance lower guide 3, a side guide plate A 5 on the operating side, and a transmission The side guide plate B 7 on the side, the calibration method is completed by the following steps:

[0009] The first step: the side guide plate A 5 and the side guide plate B 7 are installed on the slideway 4 with a beam 6 in the middle;

[0010] Step 2: Before calibration, check whether there is any foreign matter on the side guide A5 and side guide B 7 slideway;

[0011] Step 3: Open both sides of side guide plate A 5 and side guide plate B 7 to a certain extent at the same time, and manually close and open the side guide plate A 5 and side guide plate B 7 to test whether the movement is flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com