Jet fan induced draft smoke exhaust device

A technology of air induction and smoke exhaust and jet fan, which is applied in waste heat treatment, furnace, lighting and heating equipment, etc., can solve the problems of impeller dynamic balance failure, affecting the normal production of kiln, bearing bearing bush corrosion, etc., and achieve the solution of dynamic balance failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

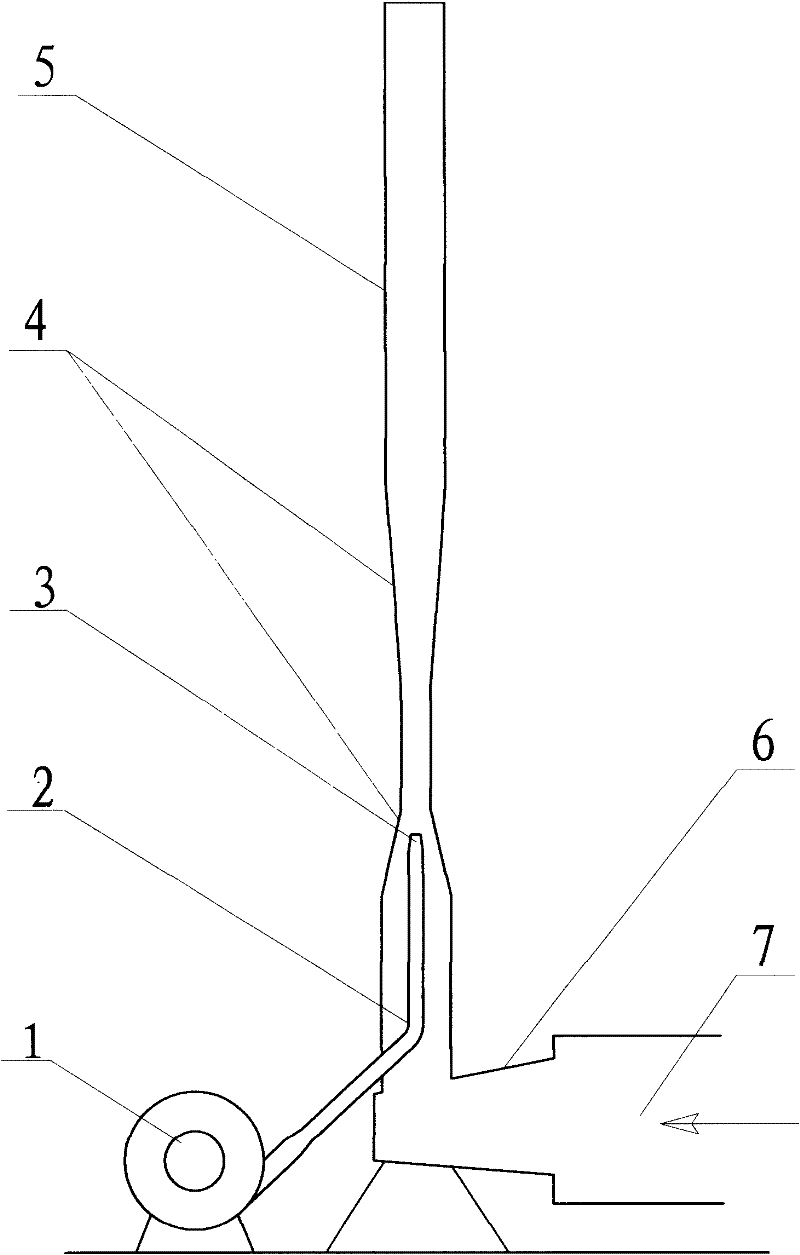

[0009] Combine below figure 1 , describe in detail the specific details and working conditions proposed by the present invention, figure 1 Among them, the end outlet of the air outlet pipe (2) connected to the fan (1) is connected with an injection port (3), and the injection port (3) is installed in the center of the jet flue (4), and the jet flue (4) is connected to the The lower end of the flue (5) is connected to the kiln tail gas inlet (6), and the tail gas inlet (6) is a kiln (7).

[0010] The present invention works like this, after the high-pressure fan (1) pressurizes the air and injects the air into the jet flue (4) at a high speed through the injection port (3), because the jet flue (4) is a continuously shrinking flue , it forms a negative pressure at the kiln exhaust gas inlet (6) with the air flowing through the high-speed jet, so that the exhaust gas in the kiln (7) is taken out to form a non-contact negative pressure smoke exhaust system, which avoids the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com