Preparation method of environment-friendly multi-scale zirconium gel dispersion plugging agent

A technology of zirconium jelly and dispersion, which is applied in the field of preparation of zirconium jelly dispersion plugging agent, which can solve the problems of poor environmental protection, jelly freezing time, difficulty in controlling the depth of jelly strength entering the formation, water swelling injectability and poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

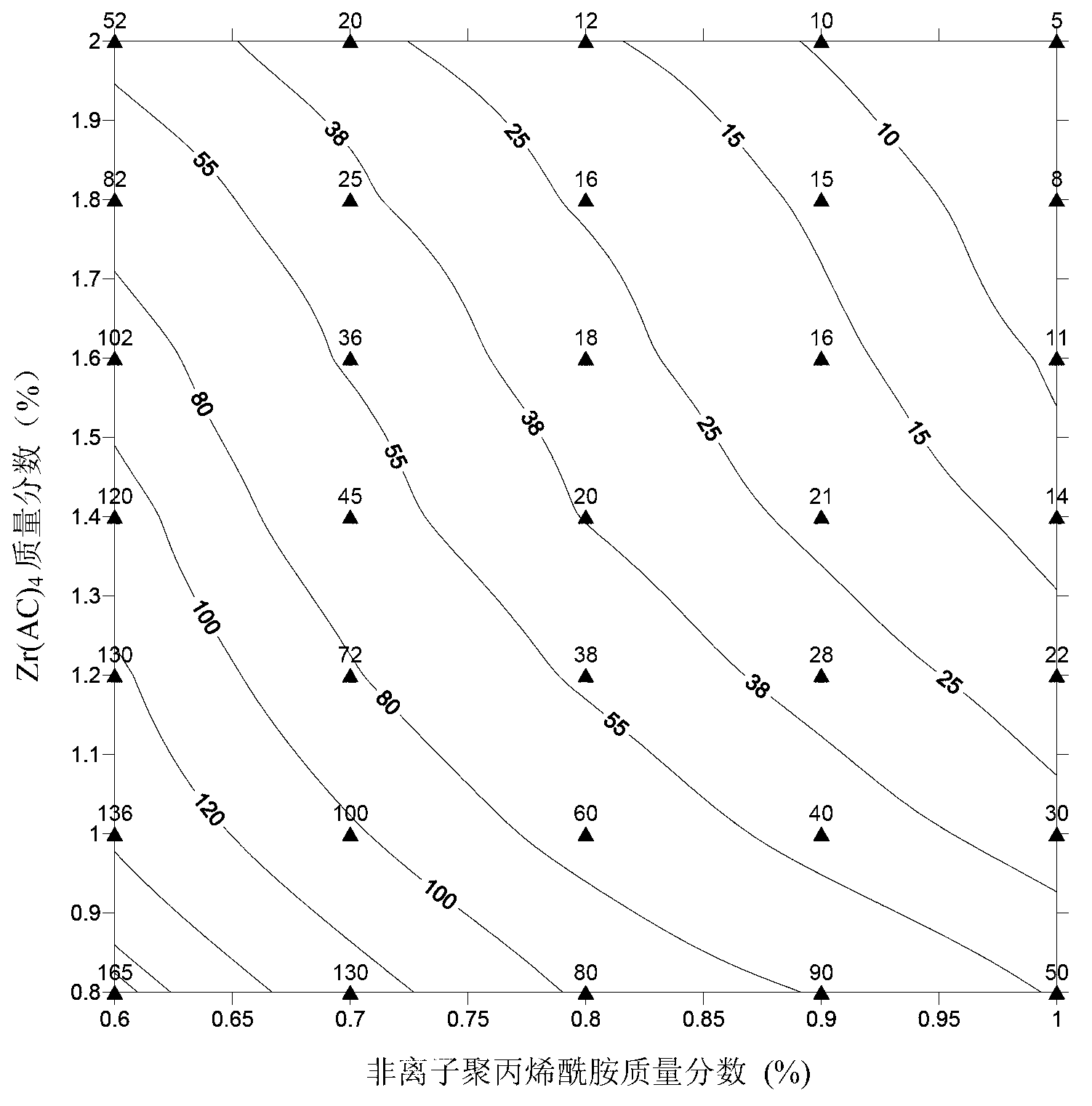

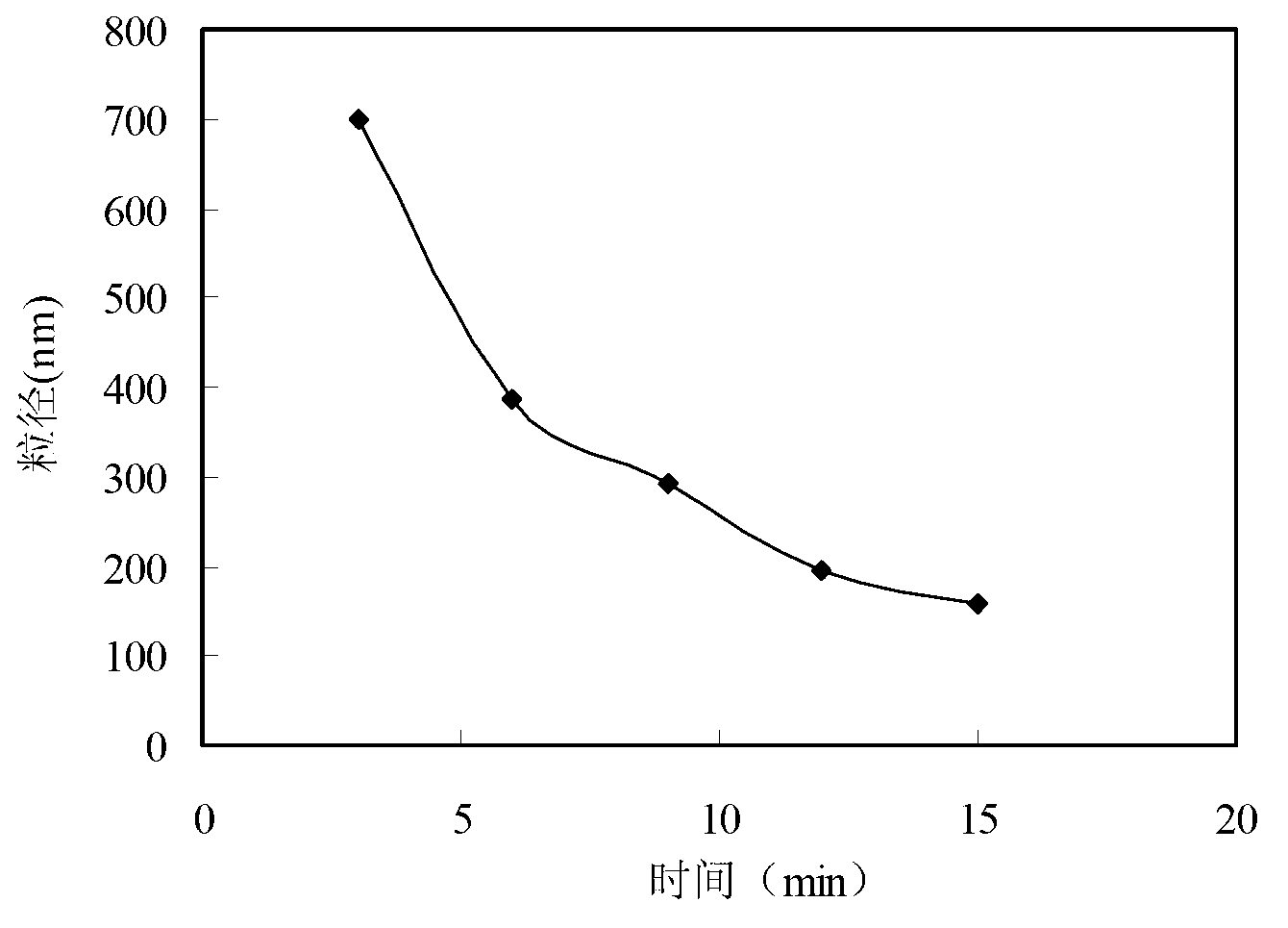

[0055] Take 200g of nonionic polyacrylamide aqueous solution, and add 3.2g of zirconium acetate solution while stirring, so that the mass fraction of zirconium acetate in the gelling solution is 1.6%, and the mass fraction of nonionic polyacrylamide is 0.6%. Stir evenly to obtain a jelly-forming liquid, and the freezing time of the jelly at 30° C. is 100 minutes. Adjust the rotation speed of the colloid mill to 3000rpm, and the shear distance is 10μm. Add the frozen whole jelly and water into the colloid mill at the same time according to the mass ratio of 5:1, and shear at a constant speed for 3 minutes until the end, and the desired nanometer High-grade jelly dispersion, which can be injected after diluting to the required concentration during on-site application.

[0056] The rotational speed of the colloid mill was fixed at 3000 rpm, the shear distance was 10 μm, and the shearing time of the colloid mill was adjusted to 6, 9, 12, and 15 minutes respectively, and the corres...

Embodiment 2

[0058] Take 200g of nonionic polyacrylamide aqueous solution, and add 3.2g of zirconium acetate solution while stirring, so that the mass fraction of zirconium acetate in the gelling solution is 1.6%, and the mass fraction of nonionic polyacrylamide is 0.6%. Stir evenly to obtain a jelly-forming liquid, and the freezing time of the jelly at 30° C. is 102 minutes. Adjust the rotation speed of the colloid mill to 2000rpm, and the shear distance is 10μm. Add the frozen whole jelly and water into the colloid mill at the same time according to the mass ratio of 5:1, and shear at a constant speed for 3 minutes until the end, and the required micron High-grade jelly dispersion, which can be injected after diluting to the required concentration during on-site application.

[0059] The fixed colloid mill rotating speed is 2000rpm, and the shear interval is 10 μm, and the colloid mill shearing time is adjusted to be 6, 9, 12, and 15 minutes respectively, and the corresponding micron-siz...

Embodiment 3

[0061] Take 200g of nonionic polyacrylamide aqueous solution, and add 3.2g of zirconium acetate solution while stirring, so that the mass fraction of zirconium acetate in the gelling solution is 1.6%, and the mass fraction of nonionic polyacrylamide is 0.6%. Stir evenly to obtain a jelly-forming liquid, and the freezing time of the jelly at 30° C. is 102 minutes. Adjust the rotation speed of the colloid mill to 1000rpm, and the shear distance is 10μm. Add the frozen whole jelly and water into the colloid mill at the same time according to the mass ratio of 5:1, and cut at a constant speed for 3 minutes until the end to obtain the required millimeter. High-grade jelly dispersion, which can be injected after diluting to the required concentration during on-site application.

[0062] Fix the colloid mill rotation speed to 1000rpm, the shear time to 3 minutes, adjust the colloid mill shear spacing to 30, 50, 70, 90, 110, 130 μm respectively, and obtain the corresponding millimeter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com