Multi-block equal-fluidity energy-gathering parallel synchronous oil displacement method for heterogeneous oil reservoir

An oil displacement method and equal fluidity technology, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve problems such as ineffective water circulation, and achieve low driving resistance, small amount of displacing agent, and displacement high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

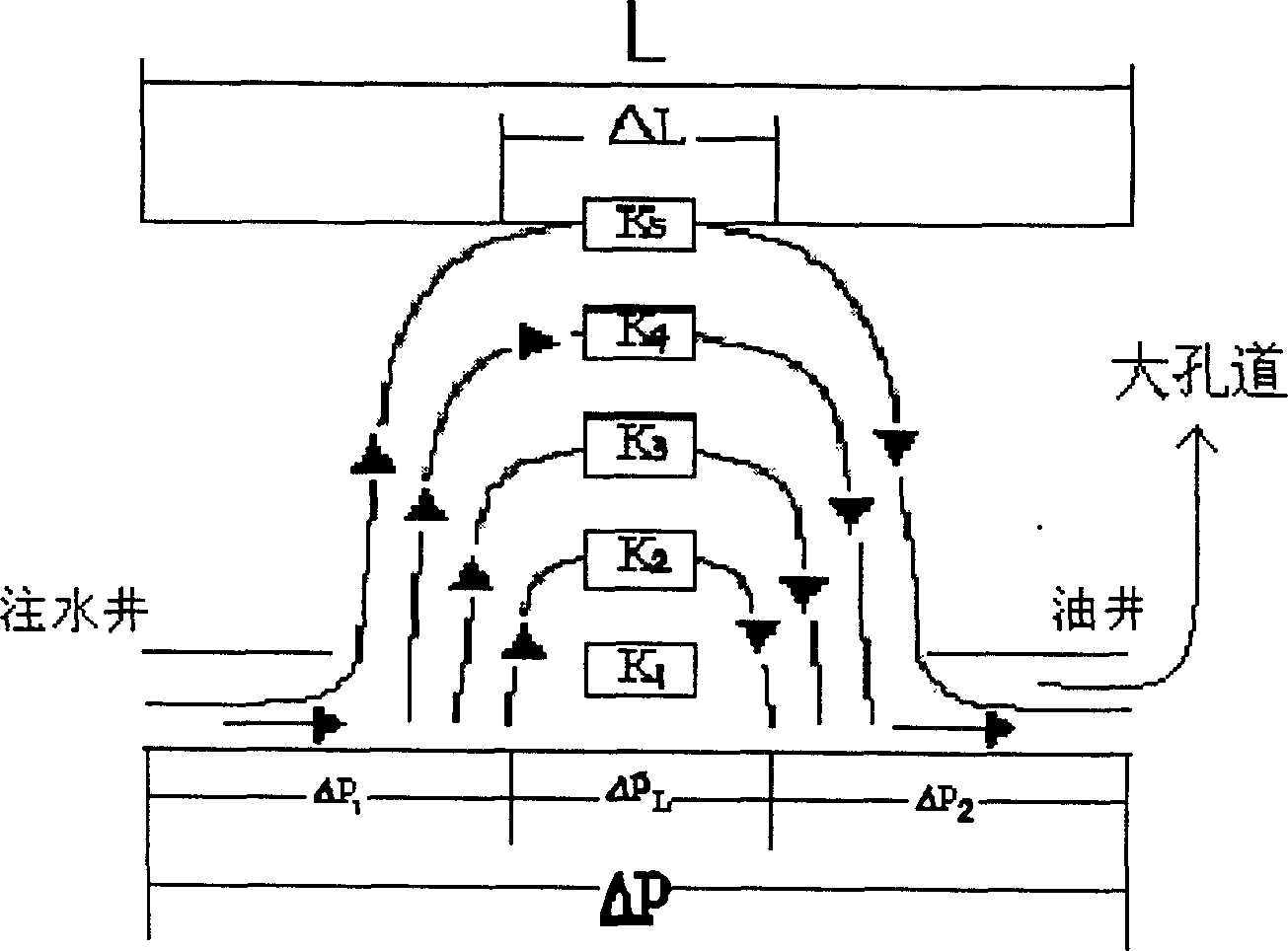

Method used

Image

Examples

Embodiment 1

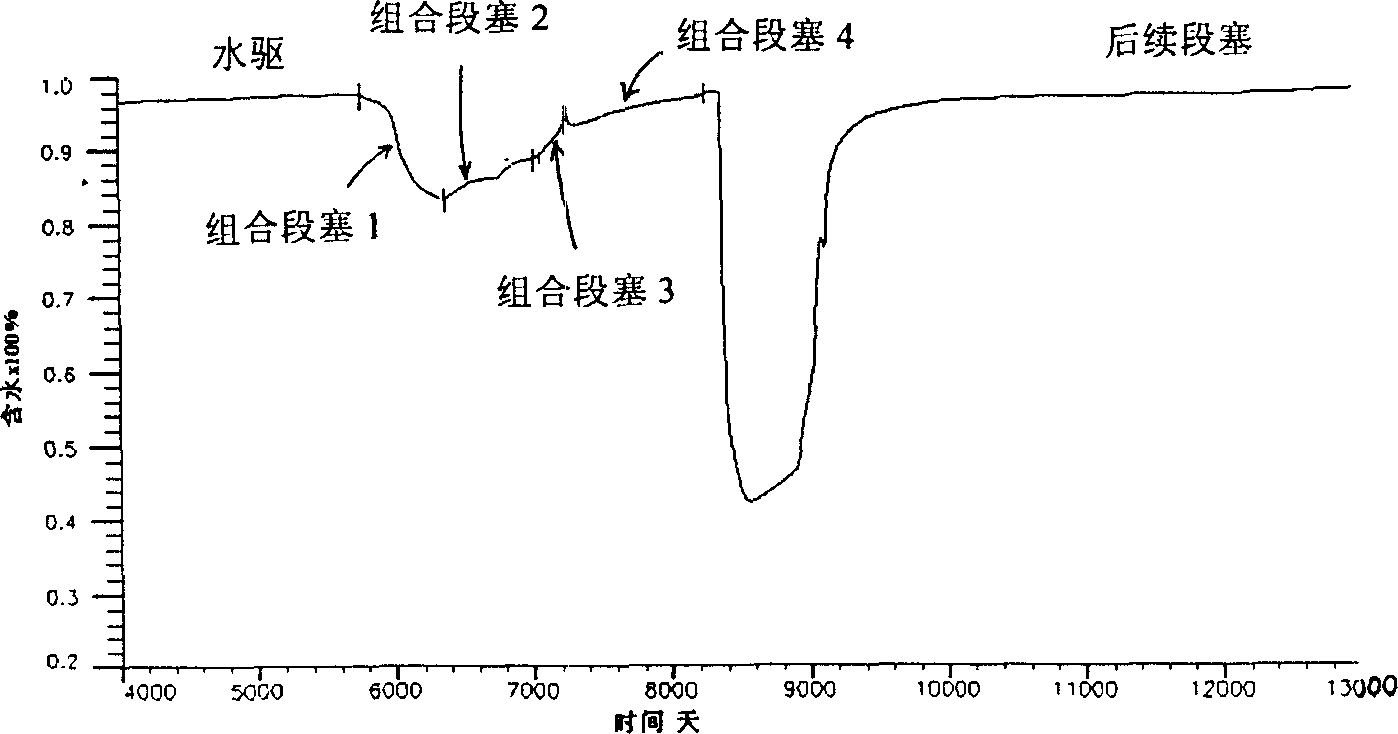

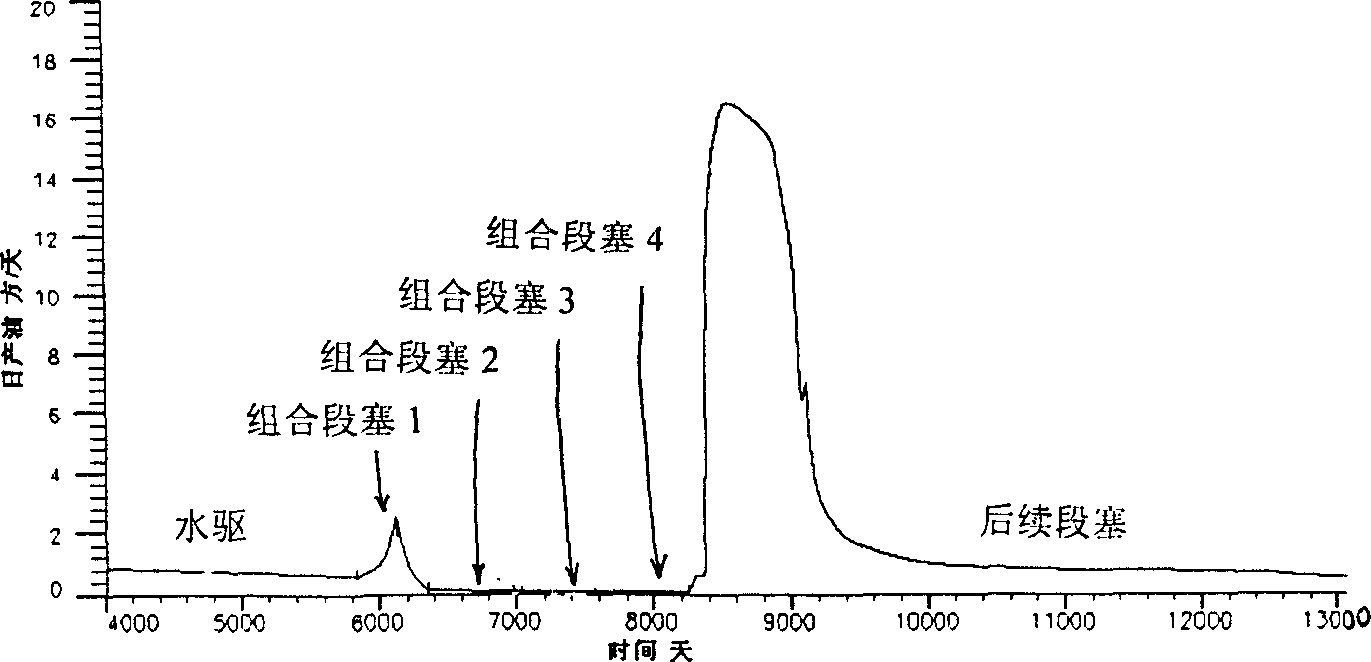

[0041] Embodiment 1: numerical simulation

[0042] (1) Reservoir model

[0043] The depth of the top of the reservoir is 1000m, and the thickness of the oil layer is 6m, with a positive rhythm distribution. Reservoir temperature is 45°C, underground crude oil viscosity is 8×10 -3 Pa.s. Original oil-gas ratio: 50, original oil saturation 80%, residual oil saturation 20%, bound water saturation 20%. The original formation pressure is 10Mpa, and the bubble point pressure is 8Mpa. See Table 2 for the distribution status of oil layers.

[0044] thickness

(m)

Penetration

(×10 -3 um 2 )

upper level

2

100

0.24

Middle

2

700

0.28

lower level

2

2200

0.34

[0045] (2) Fluid data

[0046] The specific gravity of water is 1, and the underground viscosity is 0.5×10 -3 Pa.s, oil specific gravity 0.84, rock density 1.7g / cubic centimeter.

[0047] Through labo...

Embodiment 2

[0057] Embodiment two: indoor experiment (physical simulation)

[0058] Two cuboid cores with positive rhythm distribution were prepared in the laboratory. 3×3×30cm, the high, medium and low permeability are 300, 700, 2000 mD respectively, and the thickness is equal. Under the condition of 45 degrees, the experimental brine is saturated, and then the simulated oil is saturated. The simulated oil has a viscosity of 5 mPas and is blended from crude oil and kerosene from the No. 3 Oil Production Plant in Daqing. In the experiment, the main agent of the slug is hydrolyzed polyacrylamide with a molecular weight of 2500×104. The experiment was carried out at 45 degrees. Water flooding to 98% water content first, followed by injection of two sets of slugs, each group of slugs consisting of three fluids with different viscosities, and then water flooding to 98% water content. The experiment refers to the numerical simulation and experimental conditions to select the polymer concen...

Embodiment 3

[0062] Embodiment three, field application

[0063] Ji 45 block oil-bearing area, 1.03Km 2 , geological reserves: 1.26 million tons, air permeability: 214.7×10-3μm 2 . , Interlayer permeability difference: 20.8~22.7, intralayer permeability difference: 1.6~1071 Formation temperature: 48℃. Formation water salinity: 4517mg / L, number of water injection wells: 5, number of production wells: 19, daily oil production: 45.9 tons, water cut: 84%. The slug is made of gel, and the polymer is hydrolyzed polyacrylamide, with a molecular weight of 1800×104. A combined slug (profile control slug—main slug—replacement slug) is injected, followed by water injection. The amount used is shown in Table 7:

[0064]

[0065] After the slug is injected, the oil will be increased by 40,869 tons during the effective period, the recovery rate will be increased by 6.2%, and the input-output ratio is 1:3.81.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com