Foam profile control system suitable for advanced profile control of oilfield and preparation method of foam profile control system

A foam and system technology, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve the problems of easily broken glue, unstable gel foam system, poor sealing effect, etc., and achieve strong salt resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

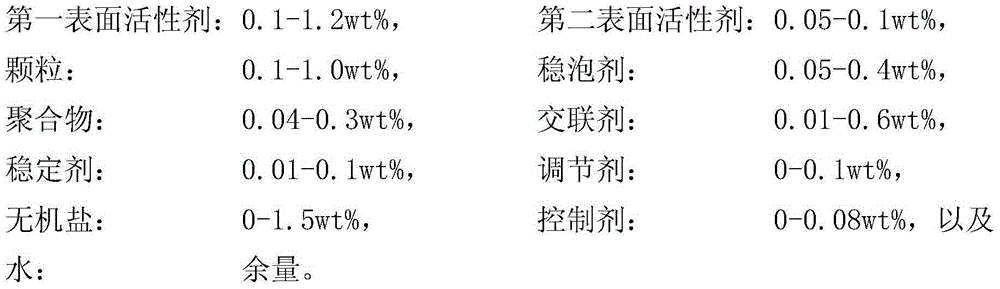

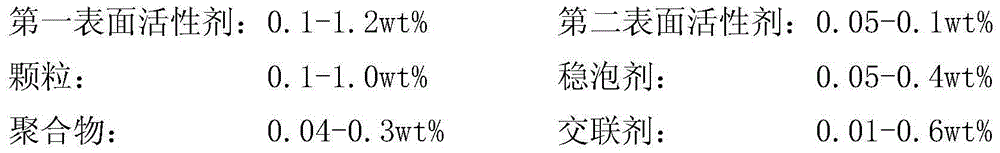

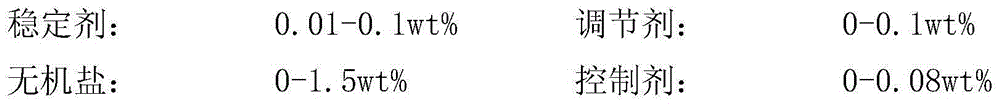

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the above-mentioned foam profile control system, comprising the following steps:

[0050] (1) Mix the second surfactant with water, stir to dissolve it completely, and obtain the second surfactant aqueous solution. Add the particles into the second surfactant aqueous solution and stir for 12 hours, and then use an ultrasonic emulsifier to homogenize and disperse for 30 minutes, so that the particles are uniformly dispersed in the second surfactant aqueous solution. Then, the first surfactant and the foam stabilizer were sequentially added into the second surfactant aqueous solution and stirred slowly for 2 hours to obtain a mixed solution A of the first surfactant, the second surfactant, granules and the foam stabilizer;

[0051] (2) Mix the polymer, inorganic salt and water, stir for 2 h to dissolve completely, and obtain a polymer solution. Then add the crosslinking agent, stabilizer, and regulator into the ...

Embodiment 1

[0057] Embodiment 1, parameters and foam performance of foam profile control system

[0058] Table 1 provides specific examples 1-6 of foam profile control systems suitable for oilfield depth profile control. All are prepared according to the preparation method of the above-mentioned foam profile control system. Then the interfacial tension, bubble volume, foam half-life, gelation time and gel strength at each temperature were measured.

[0059] The US TX500C spinning drop interfacial tensiometer was used to measure the oil-water interfacial tension at 45°C and 4000 rpm. The oil used in the experiment was Daqing crude oil. The foaming ability and foam stabilizing ability of the foam profile control system were measured by Roche foam meter and ultrasonic emulsification machine (manufactured by Hangzhou Chenggong Ultrasonic Equipment Co., Ltd., the instrument model is YPSH520202). Inject carbon dioxide, natural gas or nitrogen into the profile control system for 5 minutes, mix...

Embodiment 2

[0065] Embodiment 2, oil displacement effect of foam profile control system

[0066] 1. Water flooding plugging experiment

[0067]Experimental research method of water flooding foam plugging: a) In a constant temperature box at 90°C, select parallel sand-packing pipes with permeability of 600mD (low-permeability sand-filling pipes) and 3000mD (high-permeability sand-filling pipes). It is 120cm and the diameter is 2.4cm. Evacuate the saturated water in the sand-filled pipe, measure the volume of saturated water, and obtain the pore volume of the sand-filled pipe; then measure the water permeability. b) Inject crude oil into the sand filling pipe, measure the volume of water flowing out from the outlet end, which is the volume of saturated crude oil in the sand filling pipe; the ratio of crude oil volume to pore volume is the oil saturation. c) Water flooding to a water cut above 98%, calculate the diversion rate and recovery factor of the high-permeability and low-permeabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com