Drilling wastes recycling method

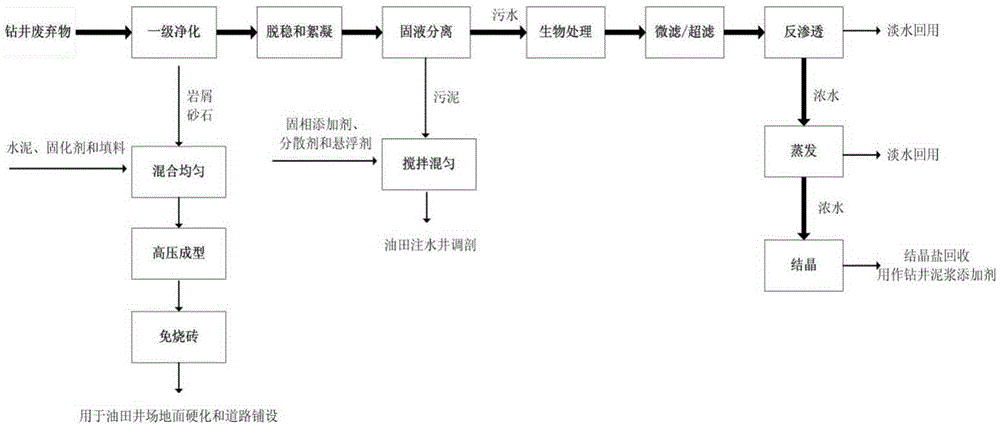

A drilling waste recycling technology, applied in chemical instruments and methods, mining wastewater treatment, special compound water treatment, etc., can solve the problems of incompatibility between economic benefits and environmental benefits, high and low cost of treatment, and achieve Ensure long-term stable operation, solve secondary pollution, and eliminate pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Utilize the method of the present invention to process the drilling waste of certain oil field C block, concrete steps are as follows:

[0025] (1) The drilling waste is sent to the shale shaker for primary purification, and the cuttings and sand that are larger than the diameter of the sieve hole in the drilling waste and partially smaller than the diameter of the sieve hole are solidified and removed by mechanical vibration.

[0026] Among them, the mud shaker is composed of a mud feed box, a screen box, a screen, a vibrator and a shock absorber. The mud feed box adopts a weir type, and the screen is a fully bonded ditch edge rigid screen. The size of the screen is 0.2~1.0mm; the adjustable range of screen box inclination is -2°~+1°.

[0027] The cuttings and sand obtained by solidification and removal are added with cement, curing agent and filler with a mass concentration of 20%, 10% and 3% respectively. The compressive strength of fired bricks reaches 15MPa / cm, th...

Embodiment 2

[0041] Utilize the method of the present invention to process the drilling waste of certain oil field E block, concrete steps are as follows:

[0042] (1) The drilling waste is sent to the shale shaker for primary purification, and the cuttings and sand that are larger than the diameter of the sieve hole in the drilling waste and partially smaller than the diameter of the sieve hole are solidified and removed by mechanical vibration.

[0043] Among them, the mud shaker is composed of a mud feed box, a screen box, a screen, a vibrator and a shock absorber. The mud feed box adopts a box type, and the screen is a fully bonded ditch edge rigid screen. 1.0~2.0mm; the adjustable range of screen box inclination is +1°~+3°.

[0044] The cuttings and sand obtained by solidifying and removing are added cement, curing agent and filler with a mass concentration of 10%, 8% and 2% respectively. The compressive strength of fired bricks reaches 18MPa / cm, the flexural strength reaches 3.2MPa,...

Embodiment 3

[0057] Utilize the method of the present invention to process the drilling waste of certain oilfield P block, concrete steps are as follows:

[0058] (2) The drilling waste is sent to the shale shaker for primary purification, and the cuttings and sand that are larger than the diameter of the sieve hole in the drilling waste are solidified and removed by adsorption through mechanical vibration.

[0059] Among them, the mud shaker is composed of a mud feed box, a screen box, a screen, a vibrator and a shock absorber. The mud feed box adopts a weir type, and the screen is a fully bonded ditch edge rigid screen. The size of the screen is 2.0~4.0mm; the adjustable range of screen box inclination is -1°~+6°.

[0060] The cuttings and sand obtained by solidification and removal are added with cement, curing agent and filler with a mass concentration of 15%, 5% and 1% respectively. The compressive strength of fired bricks reaches 16MPa / cm, the flexural strength reaches 2.8MPa, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com