Corn slow-release fertilizer

A slow-release fertilizer and corn technology, which is applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of unfavorable food crop promotion and application, non-biodegradable coating materials, and narrow crop range, so as to improve the controlled release performance and nitrogen The utilization rate of the element is beneficial to the absorption and continuous utilization, and the effect of ensuring the degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation of corn slow-release fertilizer

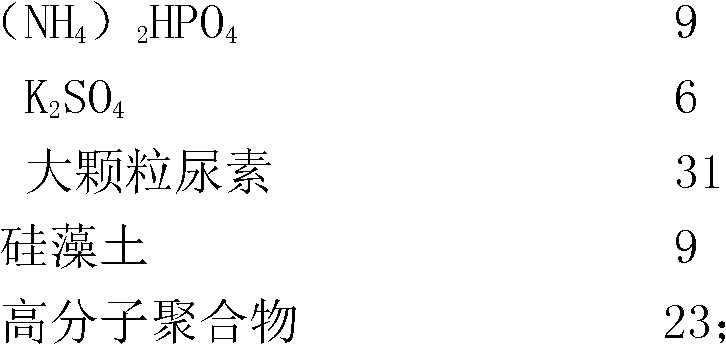

[0017] (1) Take the following components by weight (unit: kilogram):

[0018]

[0019] Wherein: the high-molecular polymer is made of the following components by weight ratio: hydroxypropyl methylcellulose: oxidized starch: polyvinyl phthalate (PVAP): Tween 80: deionized water is 24:6:7.5:0.15:45.

[0020] (2) Use the disk method to first (NH 4 ) 2 HPO 4 、K 2 SO 4 1. Large-grain urea (average particle diameter is 1.6-2.5mm) is mixed with diatomaceous earth and granulated to make the core of fertilizer granules. The average particle diameter of the fertilizer granules is 0.7-1.5cm;

[0021] (3) get the hydroxypropyl methylcellulose, oxidized starch, polyvinyl phthalate (PVAP) of described weight ratio respectively, then will be poured into the container that fills Tween 80 and deionized water , at 28°C, shear and emulsify at 10000r / mim for 35mim to obtain a polymer emulsion;

[0022] (4) Pour the ...

Embodiment 2

[0024] Embodiment 2: the preparation of corn slow-release fertilizer

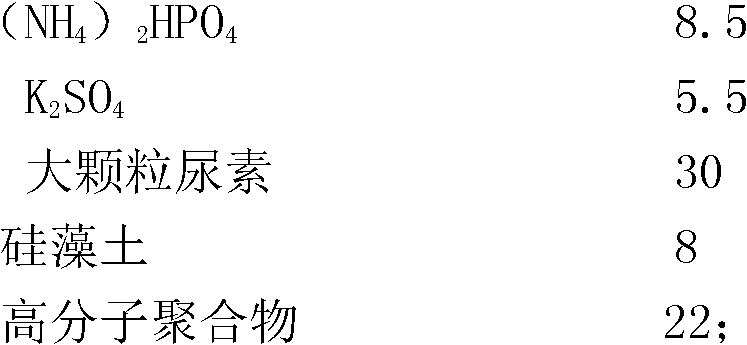

[0025] (1) Take the following components by weight (unit: kilogram):

[0026]

[0027] Wherein: the polymer is made of the following components by weight ratio: hydroxypropyl methylcellulose: oxidized starch: polyvinyl phthalate: Tween 80: deionized water is 24:6 :7.5:0.15:45.

[0028] (2) Use the disk method to first (NH 4 ) 2 HPO 4 、K 2 SO 4 1. Large granule urea (average particle size is 1.6-2.5mm) is mixed with diatomaceous earth and granulated to make the core of fertilizer granules;

[0029] (3) get the hydroxypropyl methylcellulose, oxidized starch, polyvinyl phthalate (PVAP) of described weight ratio respectively, then will be poured into the container that fills Tween 80 and deionized water , at 25°C, shear and emulsify at 10000r / mim for 30mim to obtain a polymer emulsion;

[0030] (4) Pour the fertilizer granules made in step (2) into the heating and drying drum, roll and preheat to 70°...

Embodiment 3

[0032] Embodiment 3: the preparation of corn slow-release fertilizer

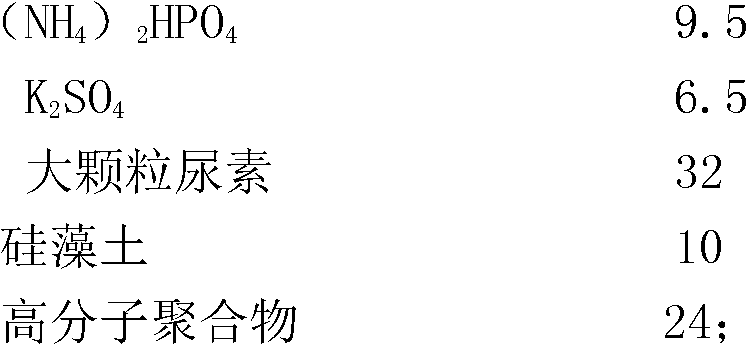

[0033] (1) Take the following components by weight (unit: kilogram):

[0034]

[0035] Wherein: the polymer is made of the following components by weight ratio: hydroxypropyl methylcellulose: oxidized starch: polyvinyl phthalate: Tween 80: deionized water is 24:6 :7.5:0.15:45.

[0036] (2) Use the disk method to first (NH 4 ) 2 HPO 4 、K 2 SO 4 1. Large granule urea (average particle size is 1.6-2.5mm) is mixed with diatomaceous earth and granulated to make the core of fertilizer granules;

[0037] (3) get the hydroxypropyl methylcellulose, oxidized starch, polyvinyl phthalate (PVAP) of described weight ratio respectively, then will be poured into the container that fills Tween 80 and deionized water , at 30°C, shear and emulsify at 10000r / mim for 50mim to obtain a polymer emulsion;

[0038] (4) Pour the fertilizer granules made in step (2) into the heating and drying drum, roll and preheat to 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com