Pneumatic de-molding type sewage treatment combined filler and matched device thereof

A combined packing and sewage treatment technology, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve the problem of affecting the contact between sewage and biofilm, the degradation of packing degradation performance, and low bio-adhesion and other problems, to achieve the effects of accelerating shedding, increasing oxygen content, and improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

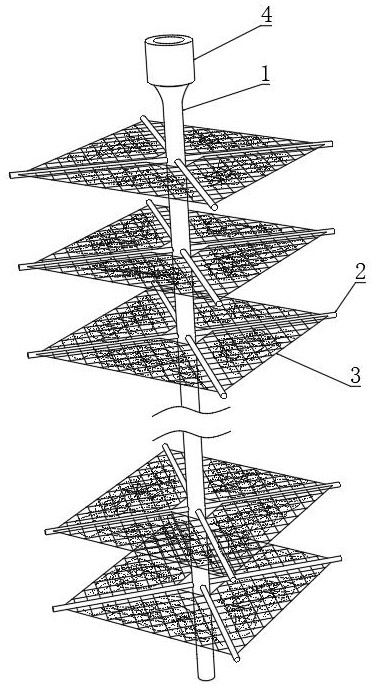

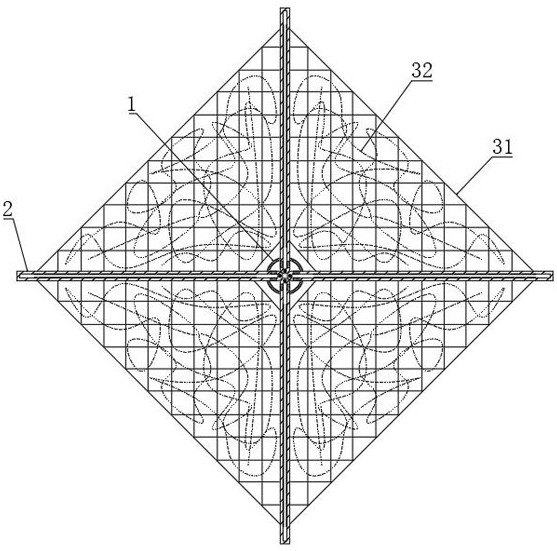

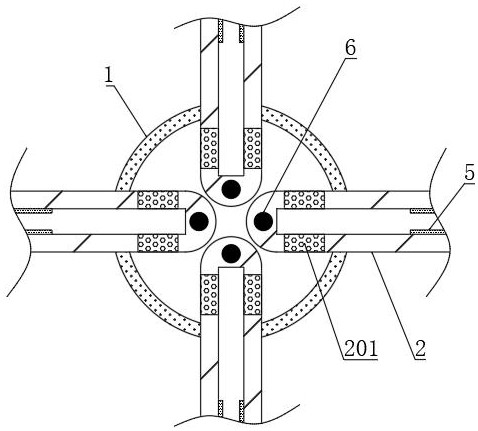

[0049] see figure 1 and figure 2 , a pneumatic off-mode sewage treatment combined filler, comprising a hollow elastic bag rope 1, a plurality of evenly distributed film-hanging monomers are arranged on the hollow elastic bag rope 1, and the film-hanging monomers include a plurality of air filter shaping tubes 2, and more A filter air shaping tube 2 is distributed on the outside of the hollow elastic bag rope 1 in a "ten" shape, and one end of the air filter shaping tube 2 runs through the outer end of the hollow elastic bag rope 1 and is fixedly connected with the hollow elastic bag rope 1, adjacent A film-attached wire mesh 3 is arranged between a pair of air filter shaping tubes 2. The film-attached wire mesh 3 is located outside the hollow elastic bag rope 1. The film-attached wire mesh 3 includes a carrier fixedly connected to the filter air shaping tube 2. The net 31 and the carrier net 31 are intertwined with a plurality of wrapping filaments 32, the carrier net 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com