Degradable high-barrier composite film and preparation method thereof

A high-barrier composite film and degradable polymer technology, applied in the field of packaging films, can solve the problems of complex processing, high price, and difficult recycling of different materials, achieve peel strength between layers, good barrier properties, and ensure compost degradability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

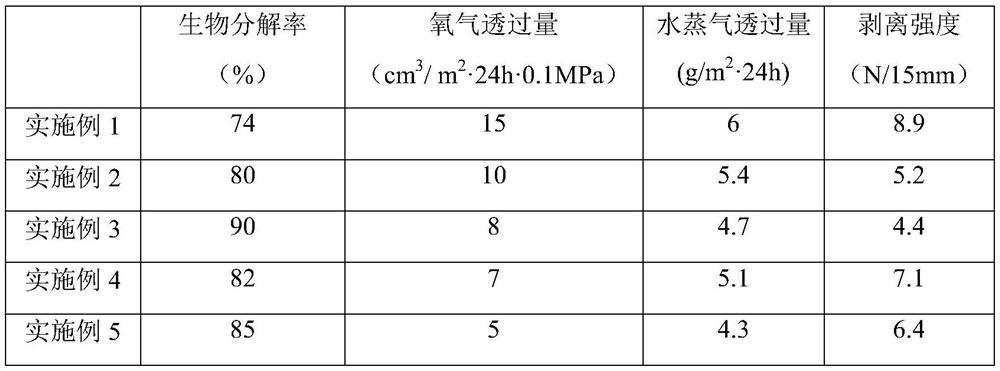

Examples

Embodiment 1

[0037] A biodegradable high-barrier composite film has an A / C double-layer structure.

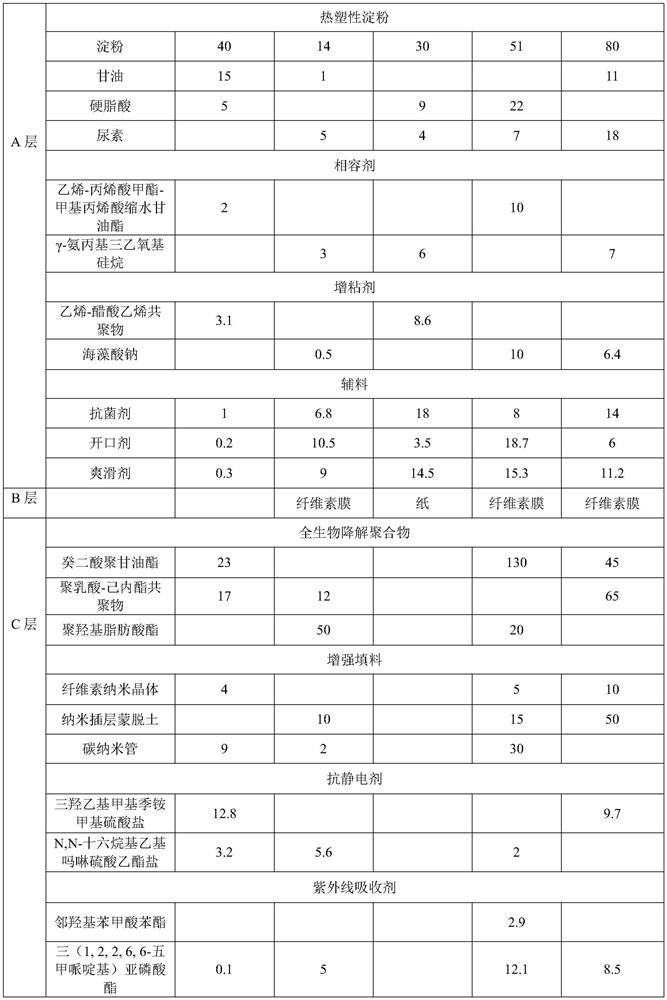

[0038] The layer A has a thickness of 50 μm and is processed from modified polybutylene terephthalate-adipate copolymer particles with an average particle size of 1 mm, an intrinsic viscosity ([η]) of 0.9 dl / g, and a molecular weight of 150,000 become. The A layer includes the following components in parts by weight: 50 parts of polybutylene terephthalate-adipate copolymer, 60 parts of thermoplastic starch, 2 parts of ethylene-methyl acrylate-glycidyl methacrylate, 3.1 parts of ethylene-vinyl acetate copolymer, 1.5 parts of auxiliary materials.

[0039] The C layer has a thickness of 6 μm and contains the following components in parts by mass: 23 parts of polyglycerol sebacate, 17 parts of polylactic acid-caprolactone copolymer, 4 parts of cellulose nanocrystals, and 9 parts of carbon nanotubes , 12.8 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 3.2 parts of N,N-hexa...

Embodiment 2

[0047] A biodegradable high-barrier composite film has an A / B / C three-layer structure.

[0048] The layer A has a thickness of 55 μm, and is processed from modified polybutylene terephthalate-adipate copolymer particles with an average particle size of 3 mm, an intrinsic viscosity ([η]) of 1.2 dl / g, and a molecular weight of 100,000 become. The A layer includes the following components in parts by weight: 103 parts of polybutylene terephthalate-adipate copolymer, 20 parts of thermoplastic starch, 3 parts of γ-aminopropyl triethoxysilane, alginic acid 0.5 parts of sodium, 26.3 parts of auxiliary materials.

[0049] The B layer has a thickness of 400 μm and is made of cellulose film.

[0050] The thickness of the C layer is 230 μm, including the following components in parts by mass: 12 parts of polylactic acid-caprolactone copolymer, 50 parts of polyhydroxyalkanoate, 10 parts of nano-intercalated montmorillonite, 2 parts of carbon nanotubes 5.6 parts of N,N-hexadecylethylmor...

Embodiment 3

[0059] A biodegradable high-barrier composite film has an A / B double-layer structure.

[0060] The layer A has a thickness of 100 μm, and is processed from modified polybutylene terephthalate-adipate copolymer particles with an average particle size of 2 mm, an intrinsic viscosity ([η]) of 1.5 dl / g, and a molecular weight of 180,000 become. The A layer includes the following components in parts by weight: 80 parts of polybutylene terephthalate-adipate copolymer, 30 parts of thermoplastic starch, 6 parts of γ-aminopropyltriethoxysilane, ethylene- 8.6 parts of vinyl acetate copolymer, 35.5 parts of auxiliary materials.

[0061] The B layer has a thickness of 300 μm and is made of paper.

[0062] The preparation method of above-mentioned degradable high-barrier composite film, comprises the following steps:

[0063] S1: Dry the starch with a linearity of 25% at 60°C for 48 hours, weigh it with stearic acid and urea at a ratio of 30:9:4, add it to a high-speed mixer and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com