High-barrier polylactic acid film and preparation method thereof

A polylactic acid, high-barrier technology, applied in chemical instruments and methods, unsaturated alcohol copolymer adhesives, adhesive types, etc., can solve poor barrier properties, low oxygen barrier properties, and limit the application of polylactic acid films, etc. problem, to achieve the effect of ensuring degradability and solving poor barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

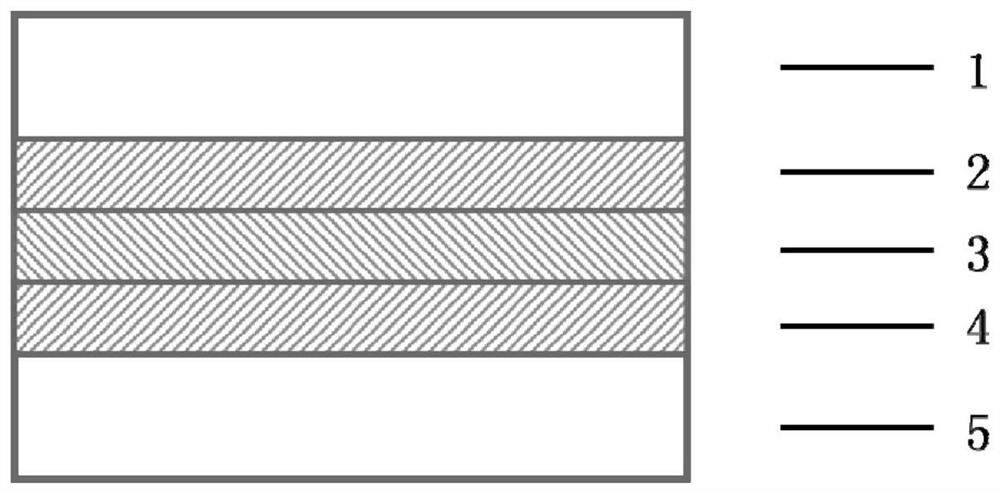

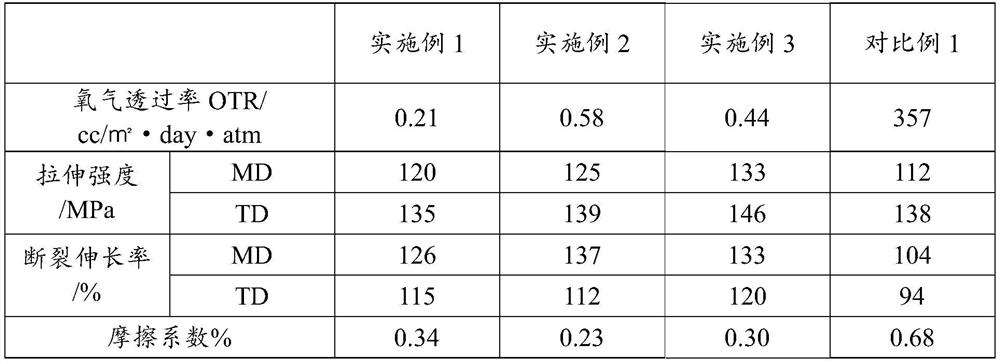

[0041] In this embodiment, a high-barrier polylactic acid film is composed of the following mass percentages: first surface layer 1 polylactic acid 99.4%, anti-blocking agent cross-linked polymethyl methacrylate particles 0.5%, erucamide 0.1%; The junction layer 2 is composed of 43% polylactic acid, 55% polyvinyl alcohol, and 2% ethylene-methyl acrylate copolymer; the barrier layer 3 is composed of 100% polyvinyl alcohol; the second adhesive layer 4 is composed of 43% polylactic acid, polyvinyl alcohol Vinyl alcohol 55%, ethylene-methyl acrylate copolymer 2%; the second surface layer 5 polylactic acid 99.4%, blocking agent cross-linked polymethyl methacrylate particles 0.5%, erucamide 0.1%. The thicknesses of the five layers are 10um / 5um / 5um / 5un / 10um respectively.

Embodiment 2

[0043]The difference between Example 2 and Example 1 is that this example is a high-barrier polylactic acid film, which is composed of the following mass percentages: first surface layer 1 polylactic acid 99.6%, anti-blocking agent cross-linked polymethyl methacrylate particles 0.2% , composed of 0.2% erucamide; the first bonding layer 2 is composed of 23% polylactic acid, 74% polyvinyl alcohol, and 3% ethylene-methyl acrylate copolymer; the barrier layer 3 is composed of 100% polyvinyl alcohol; the second The adhesive layer 4 is composed of 23% polylactic acid, 74% polyvinyl alcohol, and 3% ethylene-methyl acrylate copolymer; the second surface layer 5 is 99.6% polylactic acid, and 0.2% of cross-linked polymethyl methacrylate particles, Composition of erucamide 0.2%. The thickness of the five layers are 12um / 5um / 4um / 5un / 12um respectively.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is: this embodiment is a kind of high barrier polylactic acid film, which is composed of the following mass percentages: the first surface layer 1 polylactic acid 99.4%, anti-blocking agent cross-linked polymethyl methacrylate particles 0.3% , composed of 0.3% erucamide; the first bonding layer 2 is composed of 32% polylactic acid, 65% polyvinyl alcohol, and 3% ethylene-methyl acrylate copolymer; the barrier layer 3 is composed of 100% polyvinyl alcohol; the second The adhesive layer 4 is composed of 32% polylactic acid, 65% polyvinyl alcohol, and 3% ethylene-methyl acrylate copolymer; the second surface layer 5 is 99.4% polylactic acid, and 0.3% of cross-linked polymethyl methacrylate particles of the blocking agent. Composition of erucamide 0.3%. The thickness of the five layers are 8um / 6um / 4um / 6un / 8um respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com