Method for treating high-concentration chemical wastewater

A technology for chemical wastewater and treatment methods, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Insufficient and other problems, to achieve the effect of reducing the dosage of chemicals, compact reactor structure, and good sludge retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

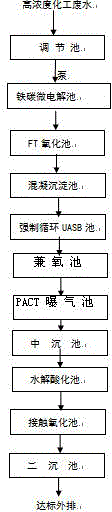

[0022] Such as figure 1 Shown: the specific process is as follows:

[0023] (a) After the wastewater passes through the grid, part of the suspended matter is removed and enters the regulating tank, and then enters the iron-carbon micro-electrolytic cell for micro-electrolysis treatment; the amount of homogeneous particle filler added is 4 times the flow rate of the wastewater.

[0024] (b) Then enter the FT oxidation pool for indirect liquefaction and oxidation of coal / natural gas, specifically: adopt a hierarchical reaction method for oxidation, add Fenton oxidizer in points and sections in the oxidation pool, and the dosage of Fenton oxidizer is wastewater 3 to 5 times the hourly flow.

[0025] (c) The wastewater from the FT oxidation tank enters the coagulation sedimentation tank, and the flocculant PAM with a concentration of 0.1% is added, and the slag and mud produced by the precipitation are transferred to the sludge thickening tank, and the sewage enters the forced ci...

Embodiment 2

[0032] On the basis of Example 1, (a) Waste water passes through the grid to remove part of the suspended matter and enters the regulating tank, and then enters the iron-carbon micro-electrolytic cell for micro-electrolysis treatment; the amount of homogeneous particle filler added is the flow rate of the waste water 6 times.

[0033] (b) Then enter the FT oxidation pool for indirect liquefaction and oxidation of coal / natural gas, specifically: adopt a hierarchical reaction method for oxidation, add Fenton oxidizer in points and sections in the oxidation pool, and the dosage of Fenton oxidizer is wastewater 3 to 5 times the hourly flow.

[0034] (c) The wastewater from the FT oxidation tank enters the coagulation sedimentation tank, and the flocculant PAM with a concentration of 0.1% is added, and the slag and mud produced by the precipitation are transferred to the sludge thickening tank, and the sewage enters the forced circulation UASB tank for further processing. Anaerobi...

Embodiment 3

[0041] On the basis of Example 1, (a) Waste water passes through the grid to remove part of the suspended matter and enters the regulating tank, and then enters the iron-carbon micro-electrolytic cell for micro-electrolysis treatment; the amount of homogeneous particle filler added is the flow rate of the waste water 5 times.

[0042] (b) Then enter the FT oxidation pool for indirect liquefaction and oxidation of coal / natural gas, specifically: adopt a hierarchical reaction method for oxidation, add Fenton oxidizer in points and sections in the oxidation pool, and the dosage of Fenton oxidizer is wastewater 3 to 5 times the hourly flow.

[0043] (c) The wastewater from the FT oxidation tank enters the coagulation sedimentation tank, and the flocculant PAM with a concentration of 0.1% is added, and the slag and mud produced by the precipitation are transferred to the sludge thickening tank, and the sewage enters the forced circulation UASB tank for further processing. Anaerobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com