Degradable polyurethane biological material and preparation method thereof

A biomaterial and polyurethane technology, applied in the field of degradable polyurethane biomaterials and its preparation, can solve the problems of slow degradation rate, low melting point, strong hydrophobicity, etc., and achieve easy processing and molding, excellent mechanical properties, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

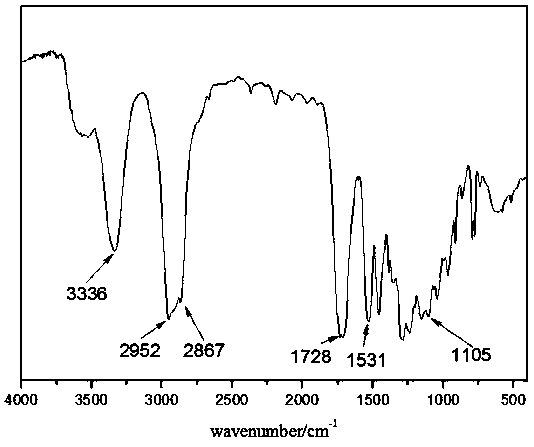

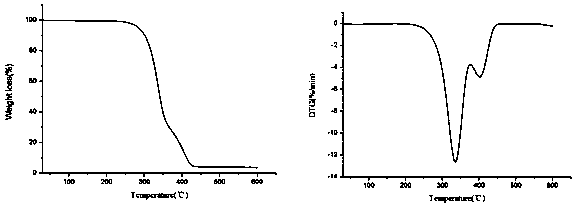

[0025] In a three-neck flask equipped with a stirring device and protected by a nitrogen atmosphere, 32g of polyε-caprolactone diol 1000 and 16g of polyethylene glycol 2000 through vacuum dehydration were added dropwise to 30.4g of isophorone diisocyanate , reacted for 3 hours at 75°C; added 10g of dimethyl carbonate and 0.2g of dibutyltin dilaurate, added 7.9g of 1,4-butanediol, and reacted for 4h at 65°C to obtain polyurethane solution; after adding 60 g of dimethyl carbonate to adjust the concentration of the solution, cast the polyurethane solution on a polytetrafluoroethylene mold, and volatilize the solvent in a fume hood at room temperature to a constant weight to obtain the desired polyurethane film.

Embodiment 2

[0027] In a three-neck flask equipped with a stirring device and protected by a nitrogen atmosphere, 32g of polyε-caprolactone diol 1000 and 8g of polyethylene glycol 1000 through vacuum dehydration were added dropwise to 30.4g of isophorone diisocyanate , under the condition of 80°C, react for 2h; after adding 10g of dimethyl carbonate and 0.2g of dibutyltin dilaurate, add 7.9g of 1,4-butanediol, and react for 4h under the condition of 70°C to obtain polyurethane solution; after adding 50 g of dimethyl carbonate to adjust the concentration of the solution, cast the polyurethane solution on a polytetrafluoroethylene mold, and volatilize the solvent in a fume hood at room temperature to constant weight to obtain the required polyurethane film.

Embodiment 3

[0029] In a three-neck flask equipped with a stirring device and protected by a nitrogen atmosphere, 64g of polyε-caprolactone diol 2000 and 16g of polyethylene glycol 2000 through vacuum dehydration were added dropwise to 30.4g of isophorone diisocyanate , under the condition of 80°C, react for 3h; after adding 15g of dimethyl carbonate and 0.3g of dibutyltin dilaurate, add 7.9g of 1,4-butanediol, and react for 5h under the condition of 70°C to obtain polyurethane solution; after adding 60 g of dimethyl carbonate to adjust the concentration of the solution, cast the polyurethane solution on a polytetrafluoroethylene mold, and volatilize the solvent in a fume hood at room temperature to a constant weight to obtain the desired polyurethane film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com