Degradable fiber and preparation method thereof

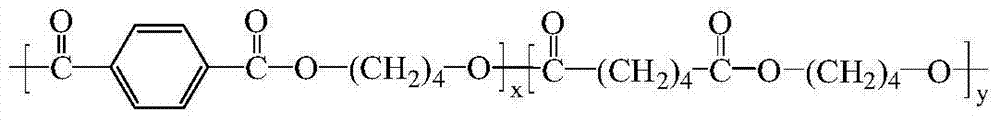

A technology for degrading fiber and butylene adipate, which is applied in the field of degradable fiber and its preparation, can solve the problems of limiting the application of polylactic acid, increasing processing steps, and poor thermal stability, so as to maintain degradability and improve compatibility properties, improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Vacuum-dry the PBAT and PLA particles, and the water content is less than 200ppm;

[0033] (2) 60 parts of PBAT, 40 parts of PLA, 0.5 parts of compatibilizer (GMA), 0.2 parts of nucleating agent (calcium stearate), 0.2 parts of antioxidant (2,6- Di-tert-butyl-4-methylphenol) are blended, melt-spun through a screw-type spinning machine, and after cooling, oiling, pre-drawing, and winding are carried out to obtain a uniform structure and controllable fineness. fiber. Wherein, the spinning temperature is 240°C, and the spinning speed is 500m / min;

[0034] (3) Drawing the fiber obtained in step (2) at a processing ratio of 1.5, a winding speed of 300m / min, and a processing temperature of 60°C to obtain a drawn filament.

Embodiment 2

[0036] (1) Vacuum-dry the PBAT and PLA particles, and the water content is less than 200ppm;

[0037] (2) After drying in step (1), 70 parts of PBAT, 25 parts of PLA, 4 parts of compatibilizer (ATBC), 1 part of nucleating agent (titanium dioxide), 0.8 parts of antioxidant (2,6-ditertiary Butyl-4-methylphenol) are blended, melt-spun by a screw-type spinning machine, and after cooling, oiling, pre-drawing, and winding are performed to obtain primary fibers with uniform structure and controllable denier. Wherein, the spinning temperature is 220°C, and the spinning speed is 800m / min;

[0038] (3) The fibers obtained in step (2) are drawn at a processing ratio of 2.1, a winding speed of 500 m / min, and a processing temperature of 80° C. to obtain drawn filaments.

Embodiment 3

[0040] (1) Vacuum-dry the PBAT and PLA particles, and the water content is less than 200ppm;

[0041] (2) 80 parts of PBAT, 15 parts of PLA, 2 parts of compatibilizer (AX8900), 2 parts of nucleating agent (calcium carbonate), 1 part of antioxidant (β-(3, 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate) for blending, melt spinning through a screw-type spinning machine, after cooling, oiling, pre-drawing, winding After treatment, the as-spun fibers with uniform structure and controllable fineness can be obtained. Wherein, the spinning temperature is 205°C, and the spinning speed is 1500m / min;

[0042] (3) Drawing the fiber obtained in step (2) at a processing ratio of 2.5, a winding speed of 600m / min, and a processing temperature of 100°C to obtain a drawn filament.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com