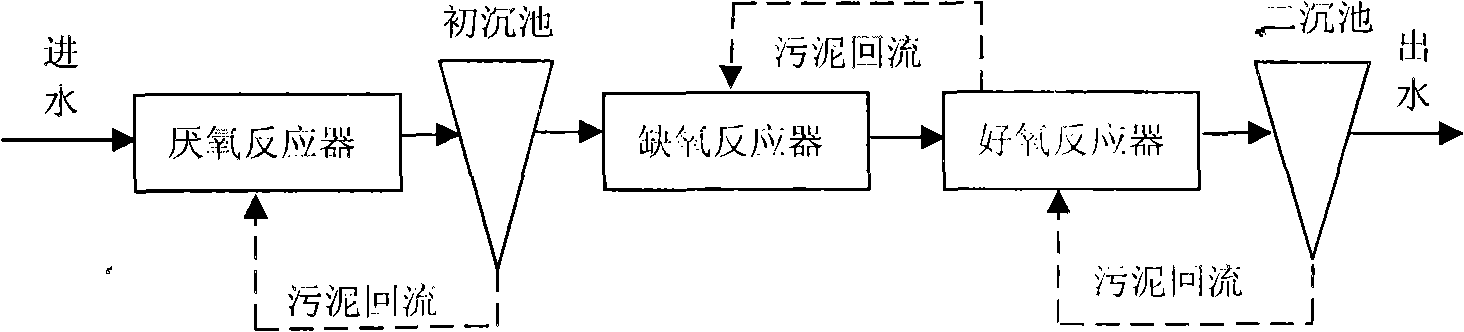

Device for improving AAO treated dyeing wastewater and method thereof

A printing and dyeing wastewater, aerobic reactor technology, applied in the textile industry wastewater treatment, aerobic and anaerobic process treatment and other directions, can solve the problems that the printing and dyeing wastewater is not easy to treat and reach the standard, and the treatment operation cost is high, and the treatment operation cost and one-time investment are achieved. The effect of low cost, convenient operation and maintenance, and simple operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

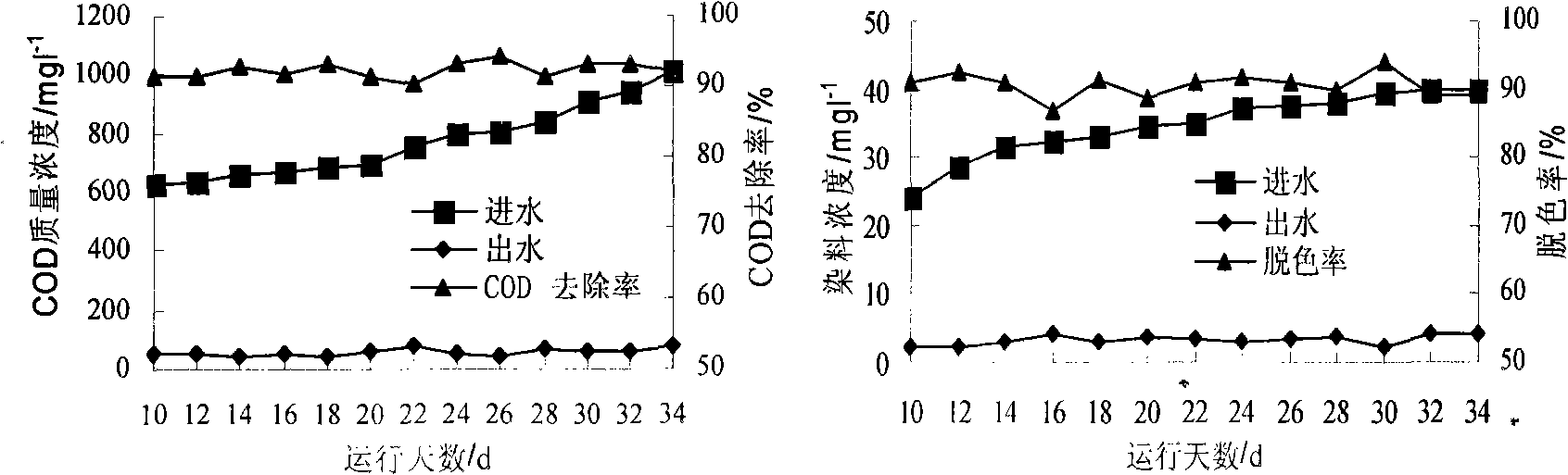

[0026] The printing and dyeing wastewater was treated by the improved AAO device.

[0027] Control the influent COD of printing and dyeing wastewater at 620-1050mg / L, and the dye concentration between 20-40mg / L. After improving the AAO treatment device, the system effluent COD and residual dyes are respectively 45-80mg / L and 2-4.5mg / L, the COD removal rate and dye decolorization rate are both greater than 90%, and the chromaticity of the effluent dye is 40-80 times.

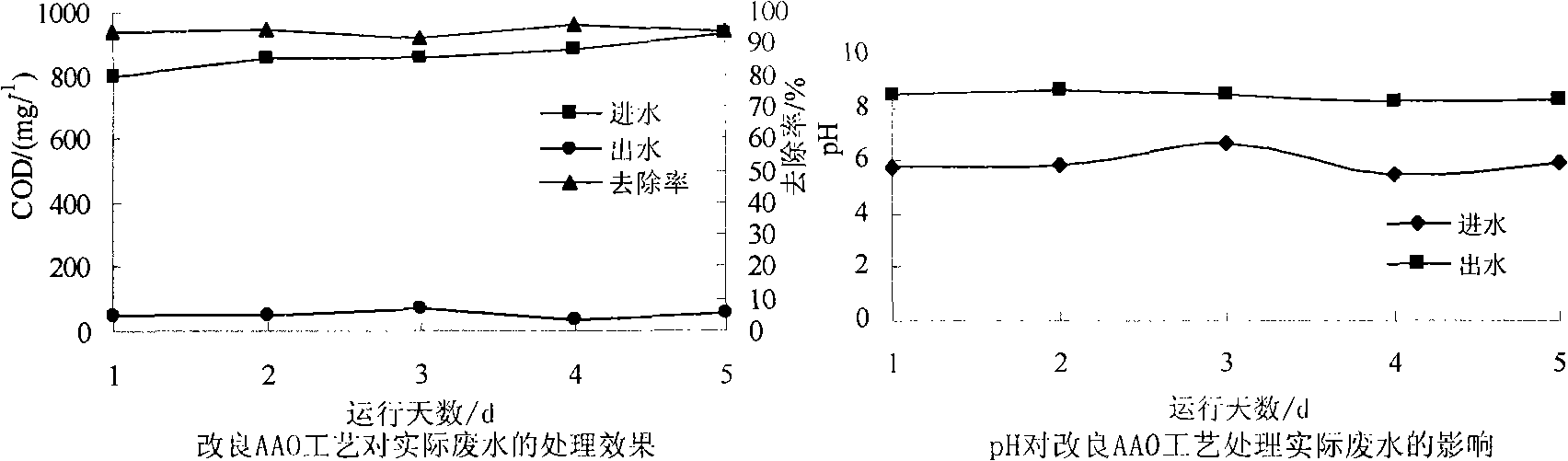

Embodiment 2

[0029] Control the COD of the actual printing and dyeing wastewater influent at 750-1000mg / L, and the pH between 5.5-7, so that the wastewater is treated by the improved AAO device. The COD removal rate, decolorization rate and pH changes of the system effluent show that the actual wastewater COD is 750 ~1000mg / L, the average removal rate of COD reaches 93.86%, the average chromaticity of the effluent is 20-40 times, the pH of the effluent is maintained between 8.26-8.66, and the COD, turbidity and chromaticity of the effluent all reach the "Urban Sewage Recycling - Industrial Water Quality" (GB / T19923-2005) requirements.

Embodiment 3

[0031] Control the influent COD of printing and dyeing wastewater at 600-1100mg / L, the dye concentration at 25-35mg / L, set the hydraulic retention time at 29h, and set the sludge age at 40 days, so that the wastewater is treated by the improved AAO device. The experimental results show that the COD removal rate and the dye decolorization rate of the system are maintained at a high level, the average COD removal rate and the average dye decolorization rate are 92.36% and 90.29%, respectively, and the concentration fluctuations of COD and dyestuff in the system effluent are small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com