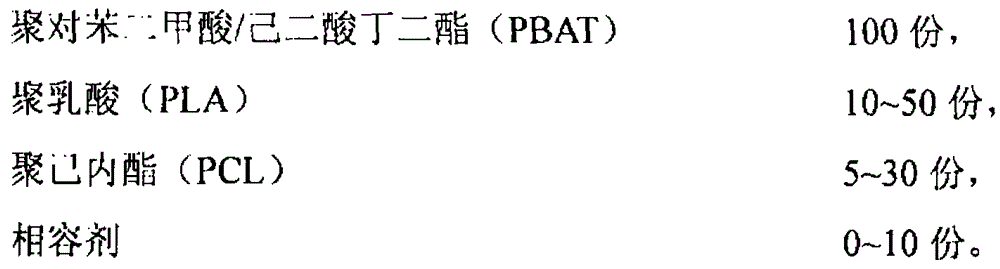

PBAT melt-blowing degradable non-woven fabric and manufacturing method thereof

A non-woven fabric and melt-blown technology, which is applied in the direction of melt spinning, non-woven fabrics, textiles and papermaking, etc., can solve the problem that the performance is difficult to meet the requirements of practical applications, the performance stability needs to be further improved, and the structure of non-woven fabric materials is not enough Uniformity and other issues, to achieve continuous and stable soft hand feeling, conducive to environmental protection, avoid or alleviate the effect of thermal degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Vacuum-dry PBAT, PLA and PCL particles at 60°C for 48 hours, and the moisture content after drying is less than 100ppm;

[0034] (2) Blend 100 parts of PBAT, 10 parts of PLA, and 5 parts of polycaprolactone (PCL) after drying for 3 minutes, heat through a screw extruder, melt at 200 ° C, and extrude into a melt. When the spinneret hole of the die head is extruded, the PBAT polyester melt is stretched into ultra-fine fibers by the high-pressure hot air flow with a flow rate of 50m / sec and a temperature of 210°C on both sides of the spinneret hole, and is condensed on the nozzle from the nozzle. On the drum-type receiver with a distance of 5cm, the drum speed of the receiver is 15r / min, and it is self-bonded into a non-woven fabric. After cooling, the non-woven fabric is removed from the drum with a blade and placed in a drying oven to dry and shape. 70°C, setting time 5h, to obtain PBAT melt-blown biodegradable non-woven fabric.

Embodiment 2

[0036] (1) Air-dry PBAT, PLA and PCL particles at 75°C for 40 hours, and the moisture content after drying is less than 100ppm;

[0037] (2) After drying, 100 parts of PBAT, 20 parts of PLA, 10 parts of polycaprolactone (PCL), and 5 parts of compatibilizer (AX8900) were blended for 5 minutes, heated by a screw extruder, and the melting temperature was 220°C , Extruded into a melt, when the melt is extruded from the spinneret hole of the die, it is blown by a high-pressure hot air flow with a flow rate of 100m / sec and a temperature of 250°C on both sides of the spinneret hole, and the PBAT polyester melt is Stretched into ultra-fine fibers, condensed on the drum receiver with a distance of 15cm from the nozzle, the drum speed of the receiver is 20r / min, self-adhesive into non-woven fabric, after cooling, use a blade to remove the non-woven fabric from the drum Put it into a drying oven to dry and set the shape, the setting temperature is 80°C, and the setting time is 15 hours t...

Embodiment 3

[0039] (1) Vacuum-dry PBAT, PLA and PCL particles at 90°C for 30 hours, and the moisture content after drying is less than 100ppm;

[0040](2) After drying, 100 parts of PBAT, 40 parts of PLA, 25 parts of polycaprolactone (PCL), and 10 parts of compatibilizer (GMA) were blended for 8 minutes, heated by a screw extruder, and the melting temperature was 270°C , Extruded into a melt, when the melt is extruded from the spinneret hole of the die head, it is blown by a high-pressure hot air flow with a flow rate of 150m / sec and a temperature of 230°C on both sides of the spinneret hole, and the PBAT polyester melt is Stretched into ultra-fine fibers, condensed on the roller receiver with a distance of 20cm from the nozzle, the roller speed of the receiver is 30r / min, self-adhesive into non-woven fabric, after cooling, use a blade to remove the non-woven fabric from the roller Put it into a drying oven to dry and set the shape, the setting temperature is 90 ° C, and the setting time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com