Inert system for civil airplane

A civil passenger aircraft, inertization technology, used in fuel tank safety measures, fire rescue and other directions, to achieve high air separation efficiency, improve flight safety, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

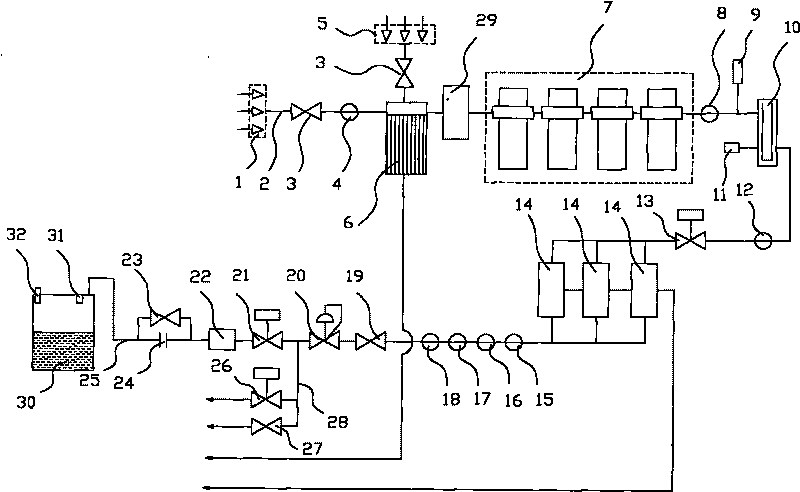

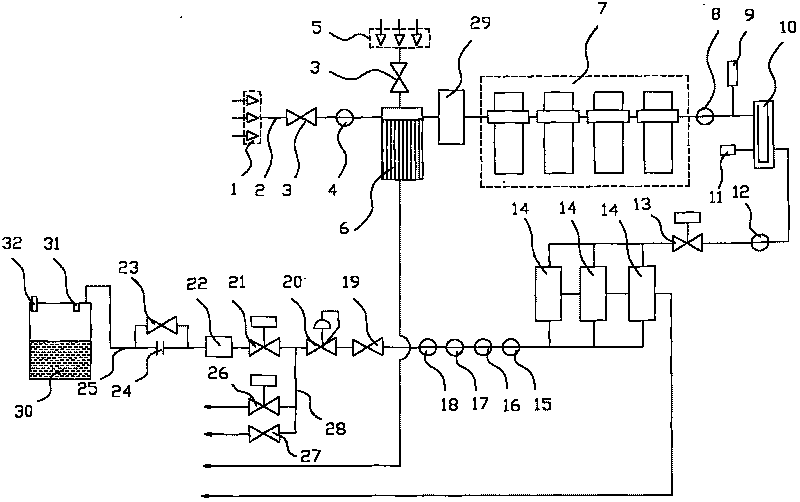

[0008] As an embodiment of the present invention, such as figure 1 As shown, an inertization system for civil passenger aircraft includes an air pretreatment system, a gas membrane separation system and an automatic control system. Under the control of the automatic control system, the compressed air is output through the air pretreatment system and the gas membrane separation system , all equipment is placed in the skid body; the air pretreatment system consists of compressed air intake pipe 2, heat exchanger 6, high-altitude deozone device 29, air filter group 7 and air heater 10 through cold and hot telescopic air pipes and The automatic control system is composed of a programmable automatic control system and a control executive electrical system. The high-temperature compressed gas generated by the aircraft engine compressor 1 provides compressed air for the compressed air intake pipe 2 through the supply pipeline. The cold air produced by the engine external duct 5 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com