Solid electrolyte and preparation method and application thereof

A technology of solid electrolyte and solid electrolyte membrane, which is applied in the direction of electrolyte, electrolyte immobilization/gelation, circuit, etc., which can solve the problems of continuous combustion, poor safety, environment and construction personnel injury, and achieve suppression of fire and explosion and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

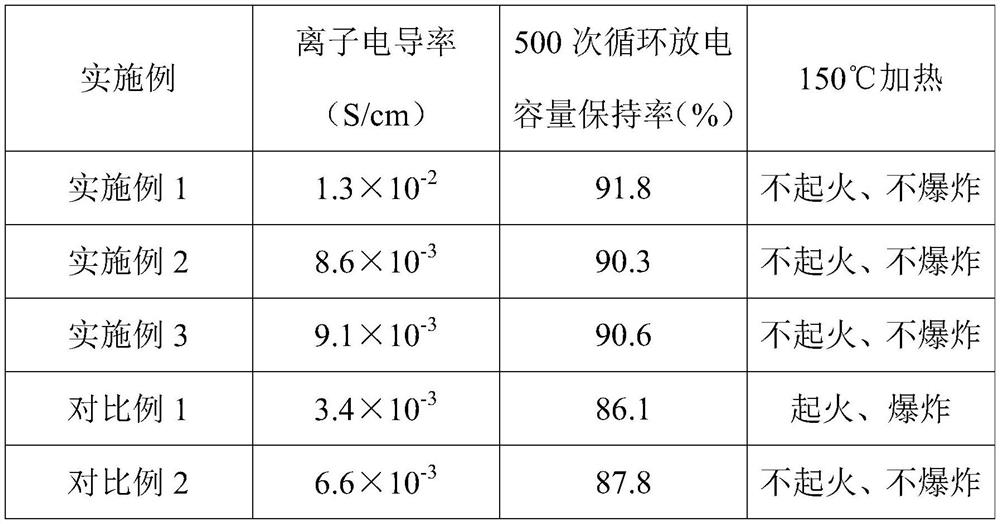

Examples

Embodiment 1

[0044] This embodiment provides a solid electrolyte, which includes flame-retardant microcapsules, polyethylene oxide powder, and ion conductor Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The flame-retardant microcapsules include a capsule wall and a core material; the capsule wall is an ethylene-vinyl acetate copolymer hot melt adhesive with a melting temperature of 110° C., and the core material is aluminum hydroxide with an average particle size of 30 nm.

[0045] The preparation method of the solid electrolyte is as follows:

[0046] (1) Add ethylene-vinyl acetate copolymer hot melt adhesive and aluminum hydroxide into acetone solvent according to the mass ratio of 20:80, and disperse by ball milling for 4 hours to obtain a mixed solution;

[0047] (2) Send the mixed liquid in step (1) into the air-flow spray dryer, the inlet and outlet temperatures are 100°C and 80°C respectively, the acetone solvent is quickly evaporated and removed, and the nanometer powder wrapped by ethylene-v...

Embodiment 2

[0051] This embodiment provides a solid electrolyte, which includes flame retardant microcapsules, polymethyl methacrylate powder and ion conductor Li 1.5 Al 0.5 Ge 1.5 (PO4) 3 ; The flame-retardant microcapsules include a capsule wall and a core material; the capsule wall is polyurethane hot melt adhesive with a melting temperature of 150° C., and the core material is zinc borate with an average particle size of 100 nm.

[0052] The preparation method of the solid electrolyte is as follows:

[0053] (1) Polyurethane hot melt adhesive and zinc borate are added in the acetone solvent according to the mass ratio of 30:70, and the ball mill is dispersed for 4 hours to obtain the mixed solution;

[0054] (2) Send the mixed solution of step (1) into the air-flow spray dryer, the inlet and outlet temperatures are 100°C and 80°C respectively, the acetone solvent is quickly evaporated and removed, and the polyurethane-wrapped nano-zinc borate flame-retardant microcapsules are obtai...

Embodiment 3

[0058] This embodiment provides a solid electrolyte, which includes flame-retardant microcapsules, polyvinylidene fluoride-hexafluoropropylene powder, and ion conductor Li 7 La 3 Zr 2 o 12 ; The flame-retardant microcapsules include a capsule wall and a core material; the capsule wall is polyamide hot-melt adhesive with a melting temperature of 180° C., and the core material is zinc borate with an average particle size of 500 nm.

[0059] The preparation method of the solid electrolyte is as follows:

[0060] (1) The polyamide hot melt adhesive and zinc borate are added in the acetone solvent according to the mass ratio of 15:85, and ball milling is dispersed for 4 hours to obtain a mixed solution;

[0061] (2) Send the mixed solution of step (1) into the air-flow spray dryer, the inlet and outlet temperatures are 100°C and 80°C respectively, the acetone solvent is quickly evaporated and removed, and the polyurethane-wrapped nano-zinc borate flame-retardant microcapsules ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com