Multi-aperture graphene film manufacturing method and gas separation element

A graphene film and a manufacturing method technology are applied in the field of multi-porous graphene film manufacturing, can solve the problems of complex operation, unclear molecular passivation mechanism, difficult control of conditions, etc., and achieve a simple preparation process and are suitable for large-scale industry. Effects of application, strong selectivity and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

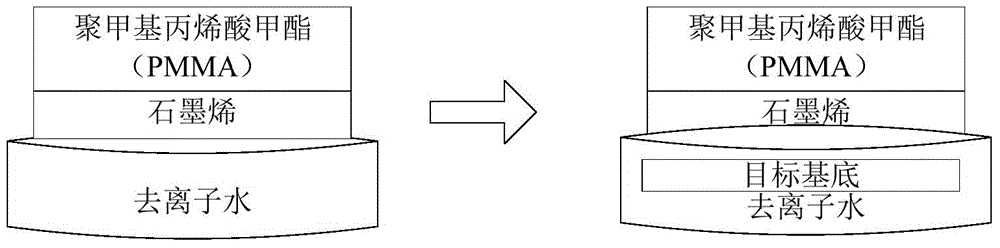

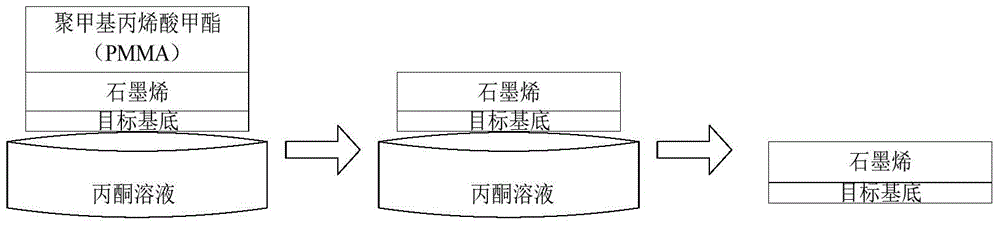

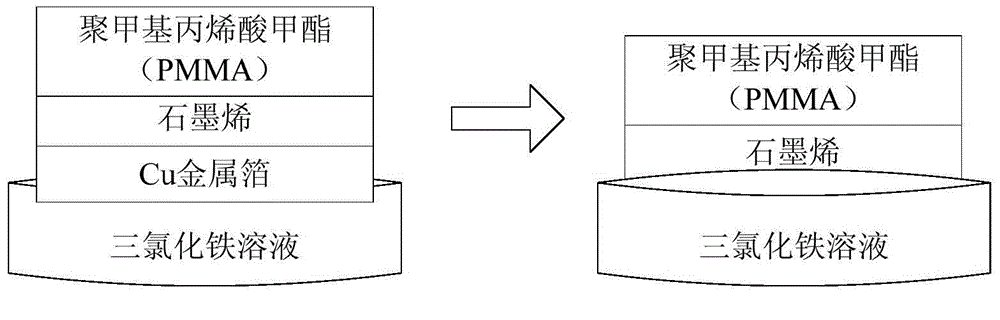

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0020] As described in the background section, although single-layer or multi-layer intrinsic graphene is theoretically considered to be an ideal membrane for permeation and separation, it cannot actually be applied to membrane separation due to the lack of channels for gas permeation. There is also no technique disclosed for producing gas permeable pores in graphene membranes. In order to solve this problem, the idea of the present invention is to consciously create lattice defects in the graphene film, and then use energy beam radiation in a certain energy range to make the graphene carbon rings without destroying the normal graphene structure. The carbon bonds with lattice defects in the hexagonal structure are broken, thereby creating pores for gas to pass through, and then obtaining a multi-aperture graphene membrane that can be used for membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com