Gas diffusion electrode of zinc-air battery and preparation method for gas diffusion electrode

A technology of gas diffusion electrodes and zinc-air batteries, which is applied to fuel cell half-cells and primary battery-type half-cells, can solve the problems of low gas permeability of polymer membranes, increase the separation coefficient, reduce the limiting current, Effect of Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

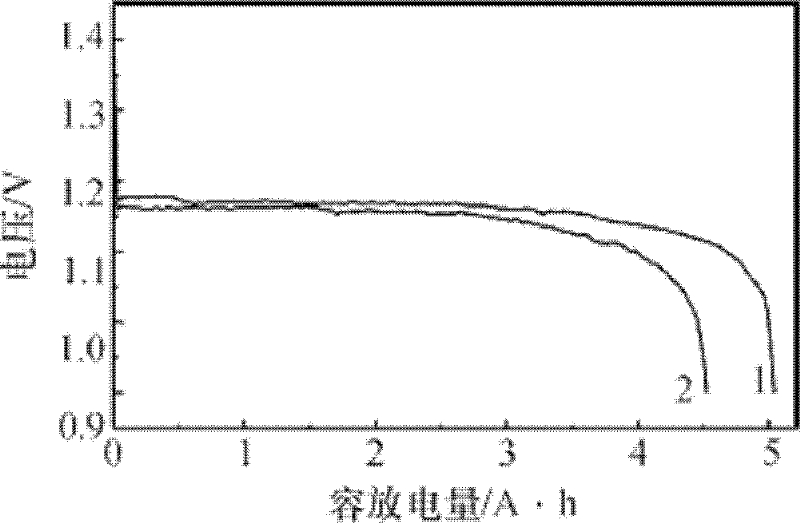

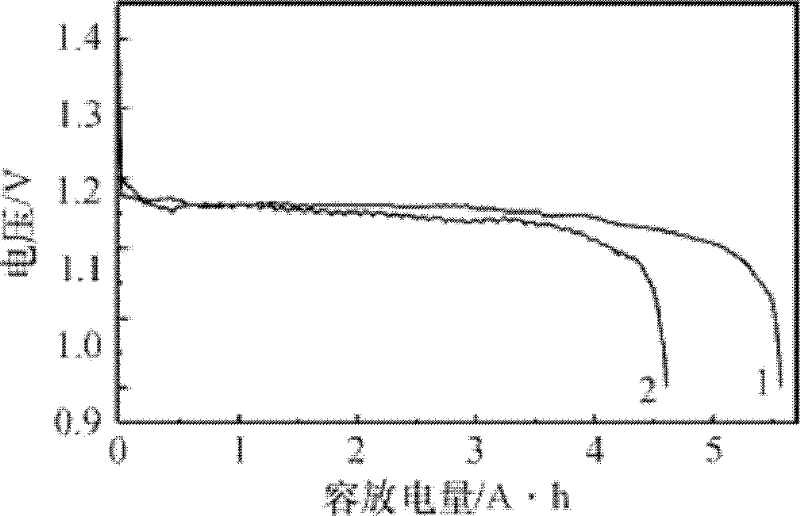

[0042] Preparation of AA-type zinc-air battery samples and determination of their discharge performance

[0043] The AA-type zinc-air battery sample adopts an external oxygen cylindrical structure, uses paste zinc paste as the negative electrode, and the diaphragm material is polypropylene non-woven fabric. The air diffusion electrode obtained by the invention is assembled into an AA-type zinc-air battery. The BS-9300 battery performance tester produced by Guangzhou Electrical Apparatus Research Institute was used to test the constant current discharge performance of AA zinc-air batteries. The discharge current of the zinc-air battery is 50mA, and the end-of-discharge voltage is 0.9V.

Embodiment 1

[0049] Air Diffusion Electrode (Uncoated Polymer)

[0050]Activated carbon, polytetrafluoroethylene emulsion (solid content is 60%), anhydrous sodium sulfate and Co-PPy-C composite catalyst (mass ratio is 4.5~7.5: 1~2.5: 1: 1~5, in this example 5: 1: 1: 3 was selected in .) mixing, with ethanol as dispersant, heated and stirred to a paste and rolled into a catalytic layer; acetylene black, polytetrafluoroethylene emulsion, anhydrous sodium sulfate (mass ratio of 7~12: 4~11: 1~4, selected 10: 5: 2 in the present embodiment.) mixing, with ethanol as dispersant, after heating and stirring until pasty, roll into a waterproof breathable layer; The waterproof and air-permeable layer, the current collector and the catalytic layer are laminated in the order of outside to inside, and then roll-formed, and dried at 70° C. for 30 minutes to obtain the air diffusion electrode 1 .

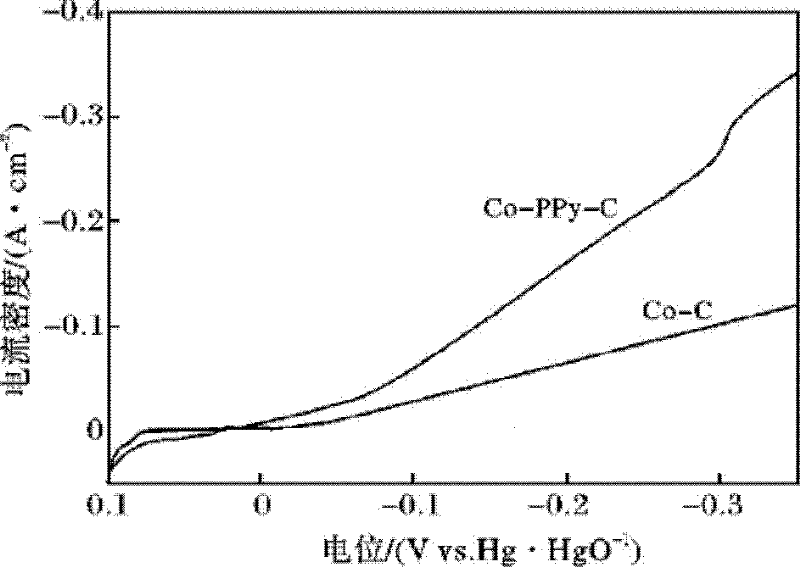

[0051] The above-mentioned Co-PPy-C composite catalyst is prepared by the following method: After mixing an...

Embodiment 2

[0054] Take 3 milliliters of 20% tetrafluoroethylene / hexafluoropropylene copolymer solution, directly apply it on the air-permeable side of the air-diffusion electrode 1, and dry it in the air for several hours to obtain the air-diffusion electrode 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com