Preparation method of coal-based carbon molecular sieve

A molecular sieve and coal-based carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low nitrogen adsorption, large methane adsorption, increased energy consumption, etc., to achieve large adsorption and process conditions Simple, good kinetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

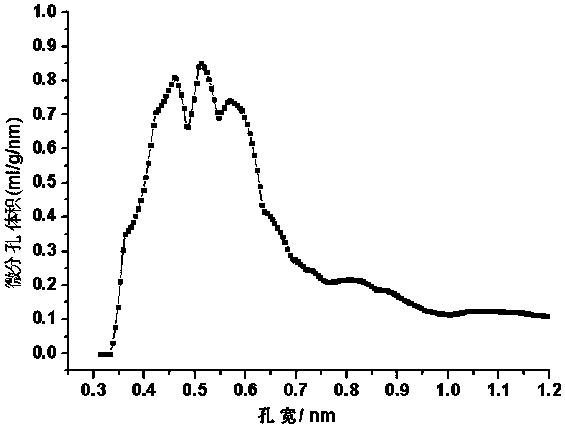

[0022] About 30g of ylang-ylang coal-based activated carbon precursor (when the pore diameter is 0.3-1nm, the pore volume is 0.25-0.30cm3 / g; when the pore size is 1-2nm, the pore volume is 0.05-0.10cm3 / g; The pore volume is 0.08~0.12cm3 / g.), after putting into the high-temperature furnace, first pass nitrogen gas for 15 minutes to drive out the air. Under adjustment, the temperature is raised to a deposition temperature of 850°C. The deposition gas is a mixture of high-concentration methane and nitrogen (the volume fraction of methane is 30%, and the flow rate of methane is 150ml / min). The deposition time is 90 minutes. After the heating is stopped, use the inert gas nitrogen. After cooling to 200°C in a high-temperature furnace at 200ml / min, move the sample to a sealed desiccator, cool to room temperature, and vacuum-seal the package. The pore size distribution of the coal-based carbon molecular sieves below 1 nm after deposition is shown in Table 1 (the pore size distributio...

Embodiment 2

[0024] The deposition time becomes 120min, and all the other test conditions are the same as in Example 1. The pore size distribution of coal-based carbon molecular sieves below 1 nm after deposition is shown in Table 1 (the pore size distribution is calculated by the HK method), see figure 1 , the static nitrogen adsorption capacity and methane adsorption capacity of the prepared coal-based carbon molecular sieve are shown in Table 1.

Embodiment 3

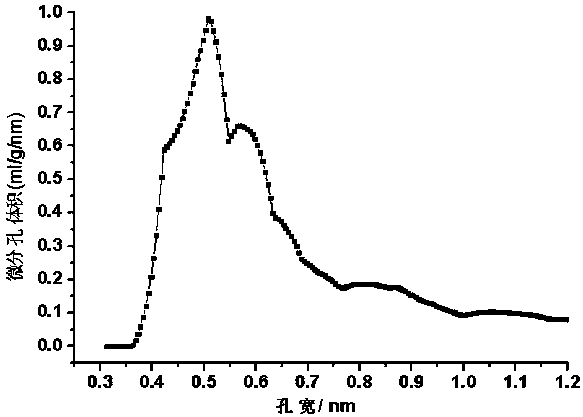

[0026] The deposition time becomes 180min, and all the other test conditions are the same as in Example 1. The pore size distribution of the coal-based carbon molecular sieves below 1 nm after deposition is shown in Table 1 (the pore size distribution is calculated by the HK method). The static nitrogen adsorption capacity and methane adsorption capacity of the prepared coal-based carbon molecular sieves are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com