Preparation method of high purity hydrogen

A preparation process and high-purity technology, applied in the field of hydrogen preparation technology, can solve the problems of reduced hydrogen production cost, small output and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

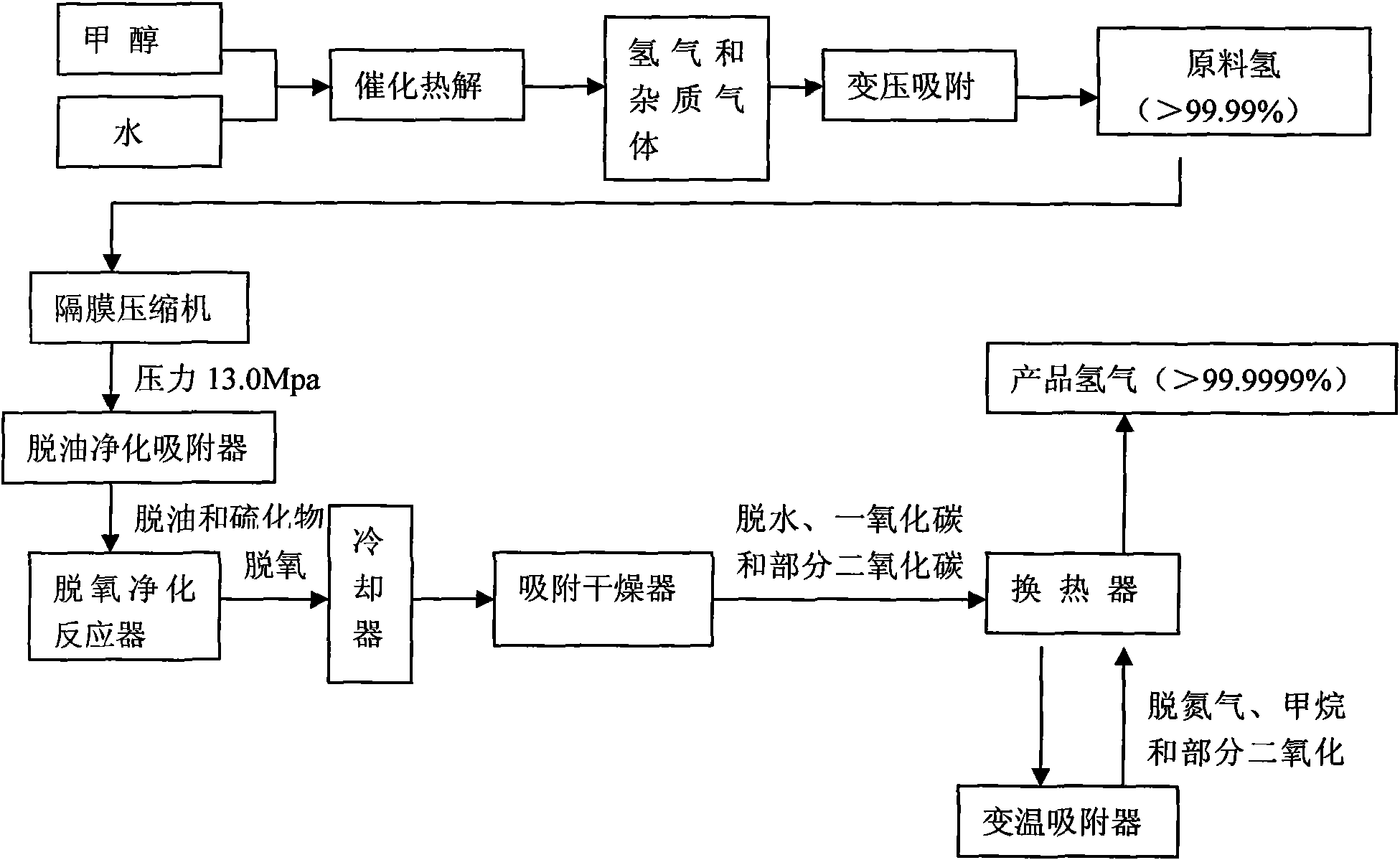

Method used

Image

Examples

Embodiment 1

[0030] Preparation of raw material hydrogen: using methanol and pure water as raw materials, at a temperature of 268°C and a pressure of 1.0Mpa, copper-based catalysts are used to catalyze and pyrolyze to obtain reformed gas mainly containing hydrogen and carbon dioxide; hydrogen and carbon dioxide reformed gas is in the adsorber Carry out pressure swing adsorption separation, fill the adsorbent with selective adsorption performance to carbon dioxide, methane and carbon monoxide in the adsorber, utilize pressure swing adsorption (PSA) technology to extract pure hydrogen from reformed gas, and the described molar ratio is methanol: water=1 : 1.14, PSA pressure 1MPa, desorption pressure 0.02Mpa, adsorption temperature: room temperature, methanol unit consumption 0.61kg / Nm 3 , The purity of the obtained hydrogen: >99.99%, the impurities and contents of the raw hydrogen are shown in Table 1. The production device for raw material gas pure hydrogen is manufactured by Sichuan Yalian...

Embodiment 2

[0037] Preparation of raw material hydrogen: molar ratio: methanol: water = 1:1.15, transformation temperature 271°C, transformation pressure 1.0MPa, pressure swing adsorption pressure 1.0MPa, desorption pressure 0.02Mpa, adsorption temperature at room temperature, methanol unit consumption 0.595kg / Nm 3 , The purity of the hydrogen obtained: >99.99%, the impurities and their contents in the raw hydrogen are shown in Table 3, and the rest are the same as in Example 1.

[0038] Impurity content (weight ratio) in the pure hydrogen raw material gas of table 3

[0039] Impurities

Content (10 -6 )

Nitrogen (N 2 )

52

Oxygen (O 2 )

4

carbon monoxide (CO)

3.6

carbon dioxide (CO 2 )

2.8

Methane (CH 4 )

3

water (H 2 O)

10

[0040] Hydrogen secondary purification: with the secondary purification method of Example 1, the product hydrogen with a purity greater than 99.9999% is obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com